Silent BOS 801

Started this project in January 2020 so I'm posting updates retroactively. Do check back over the next couple of days as I catch up to March.

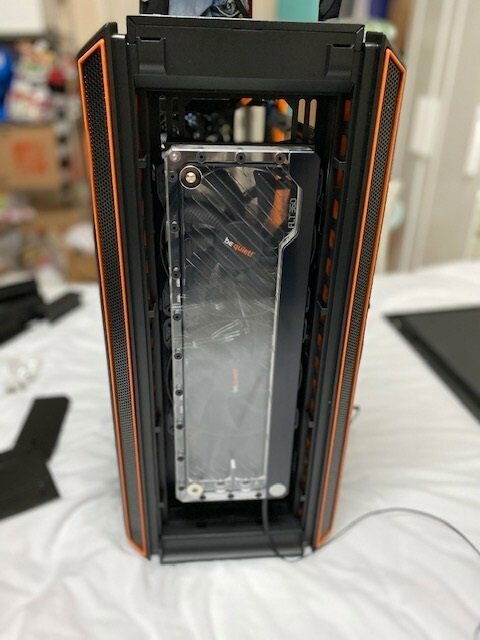

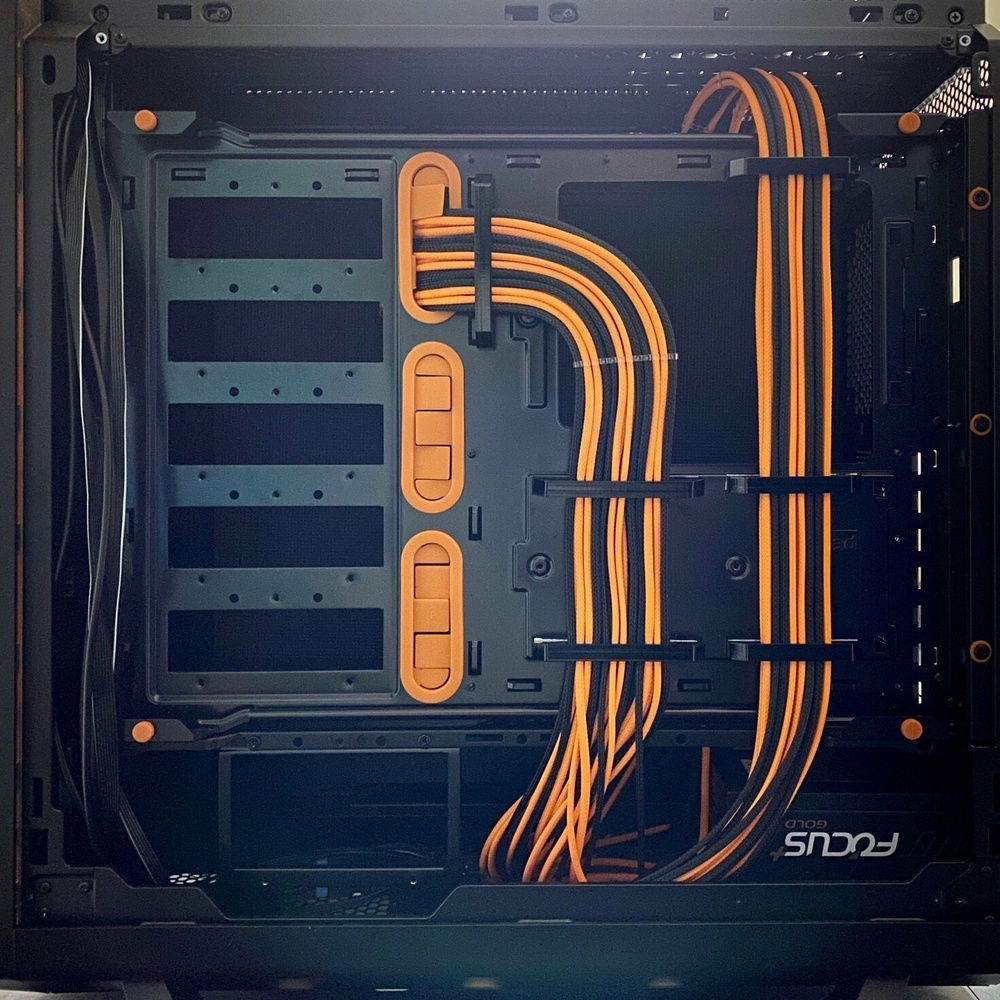

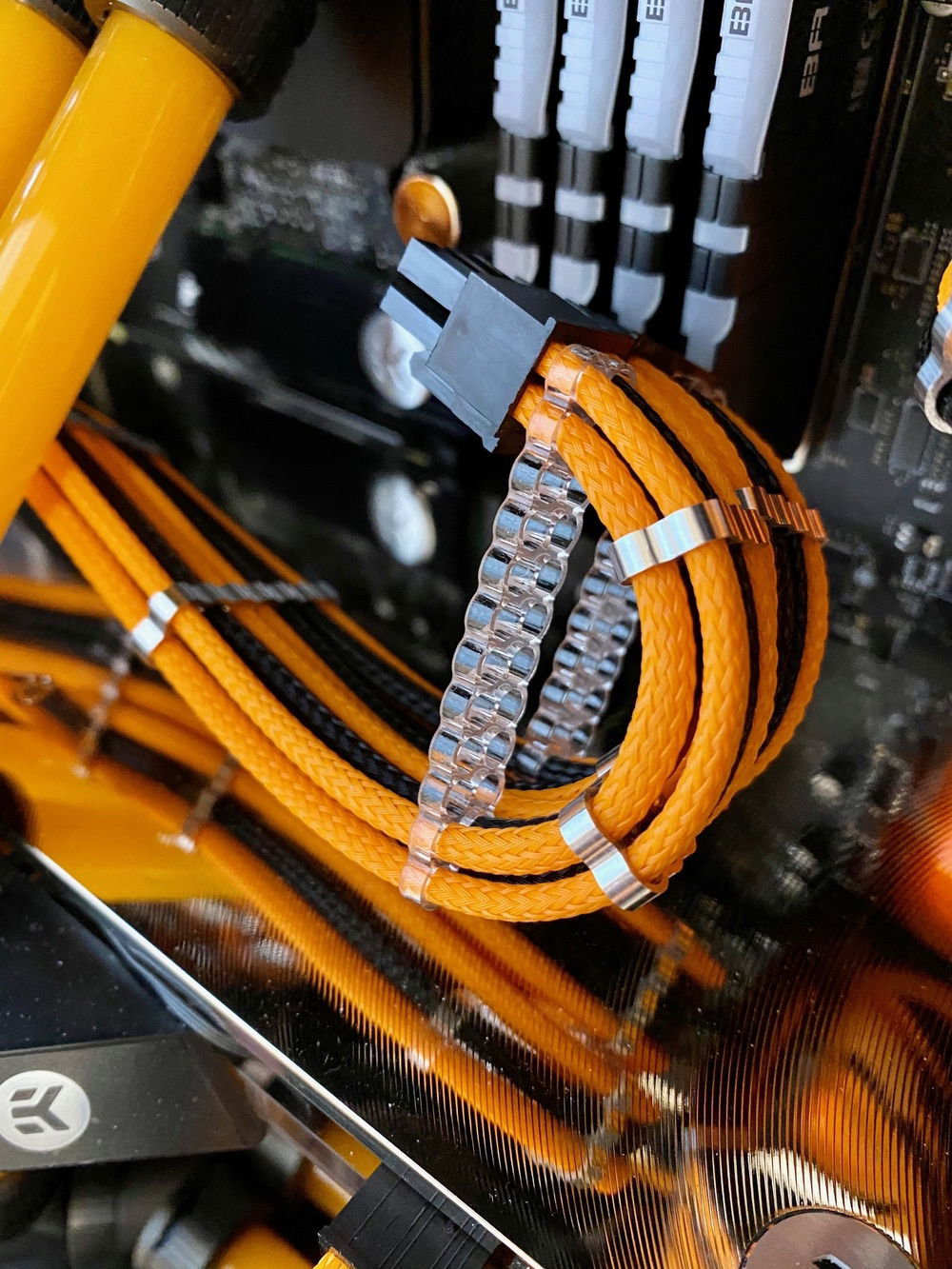

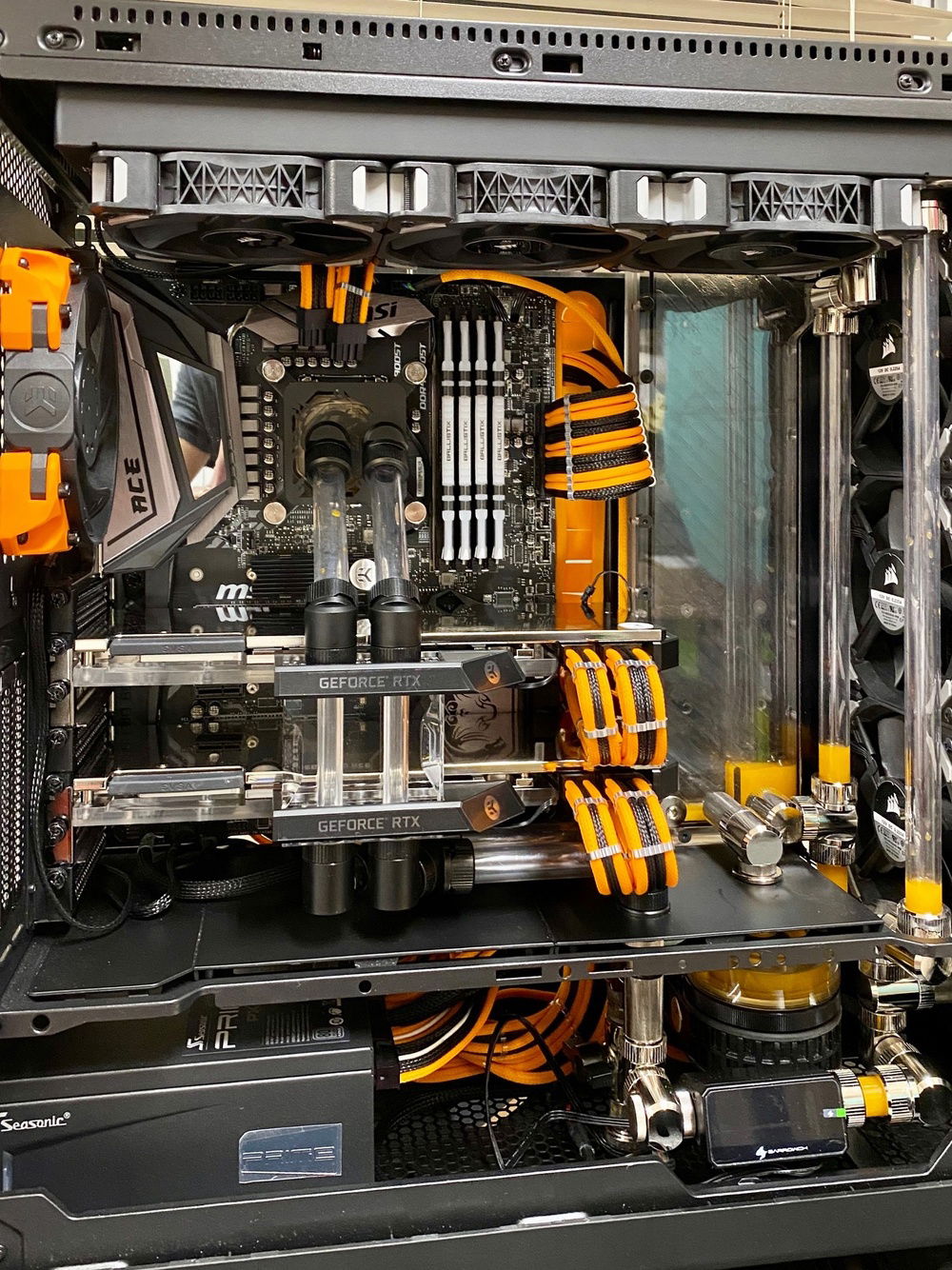

This all started out with my tinkering with an Aurora R8 which I bought mid-2019. First, the fans were too loud, then I wanted an unlocked CPU, and the next thing I know, I was cutting the R8 with a Dremel and attempting custom cable sleeving. Then over the year-end holiday, I had a bunch of rewards points to spend and I pulled the trigger on a be Quiet! Silent Base 801. I ordered a silver windowed version but BQ-USA told me they were out of stock so I settled for orange. Hence I named the build BOS for Black-Orange-Silver.

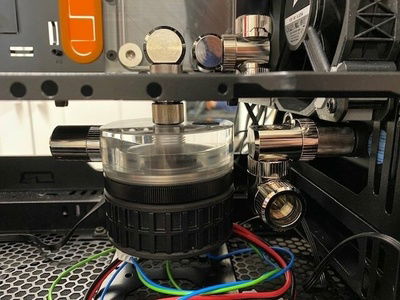

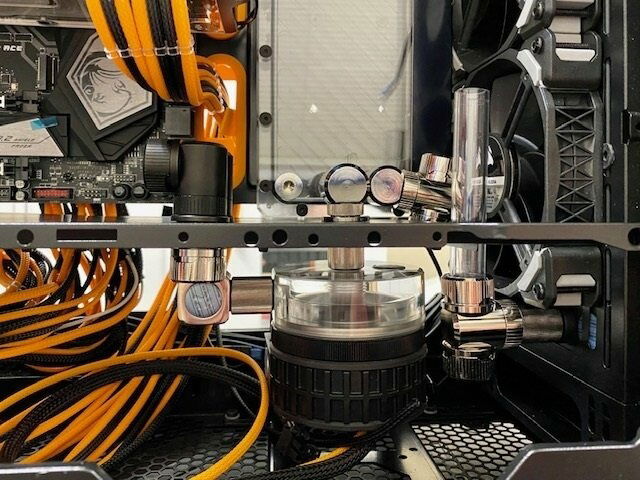

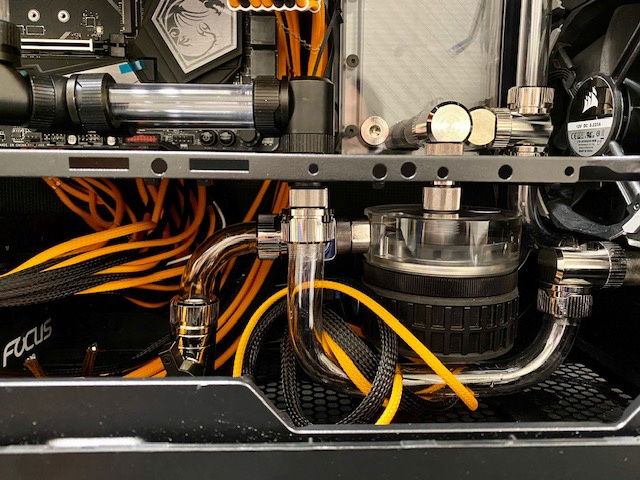

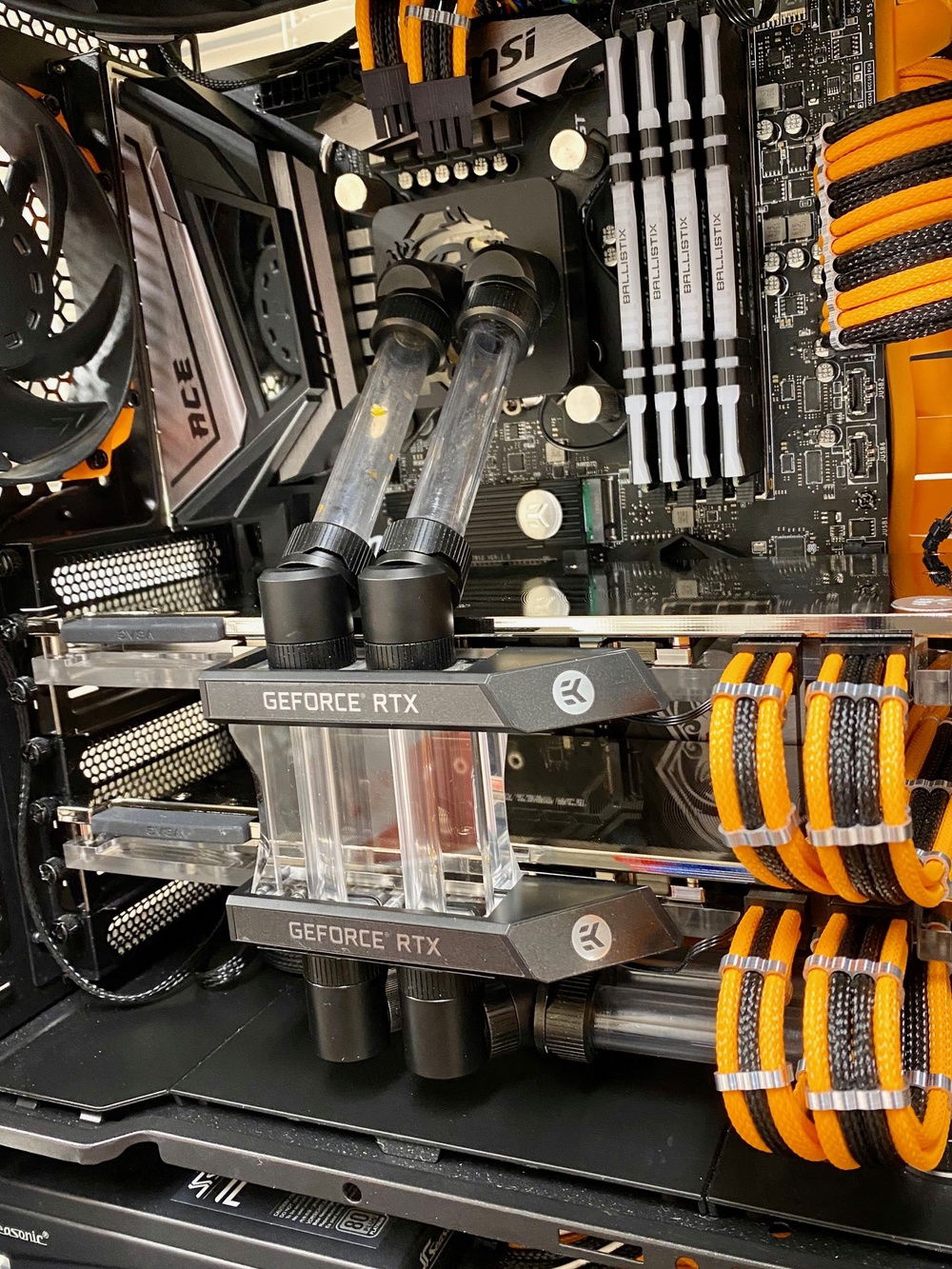

Initially meant for a case swap to bring all my components from the R8 over to this new case but then I spent remaining rewards points on a great motherboard deal. So I told myself, ok, I'll just get a nice NZXT AIO liquid cooler and call it a day. But no... EKWB just had to launch their flat reservoir. I get tempted easily by distro plates so with this looking like a vagrant-case's distro plate (hey, this is no O11D), I bought my first EK part. And like they said, the rest is history.

This all started out with my tinkering with an Aurora R8 which I bought mid-2019. First, the fans were too loud, then I wanted an unlocked CPU, and the next thing I know, I was cutting the R8 with a Dremel and attempting custom cable sleeving. Then over the year-end holiday, I had a bunch of rewards points to spend and I pulled the trigger on a be Quiet! Silent Base 801. I ordered a silver windowed version but BQ-USA told me they were out of stock so I settled for orange. Hence I named the build BOS for Black-Orange-Silver.

Initially meant for a case swap to bring all my components from the R8 over to this new case but then I spent remaining rewards points on a great motherboard deal. So I told myself, ok, I'll just get a nice NZXT AIO liquid cooler and call it a day. But no... EKWB just had to launch their flat reservoir. I get tempted easily by distro plates so with this looking like a vagrant-case's distro plate (hey, this is no O11D), I bought my first EK part. And like they said, the rest is history.

Color(s): Black Orange Silver

RGB Lighting? Yes

Theme: none

Cooling: Custom Liquid Cooling

Size: ATX

Type: General Build

Build Updates

Fixed flow meter

New Year, New Beginning

1/20 - Early parts and cable planning

1/25 - More parts-fitting

2/2 - Completed 24-pin cable + Fan-tasy

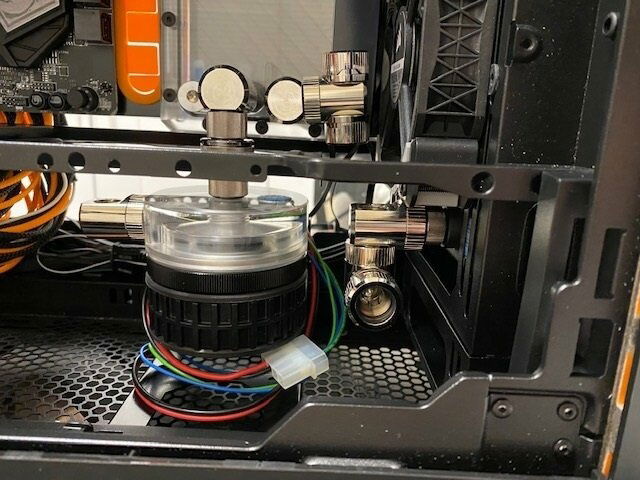

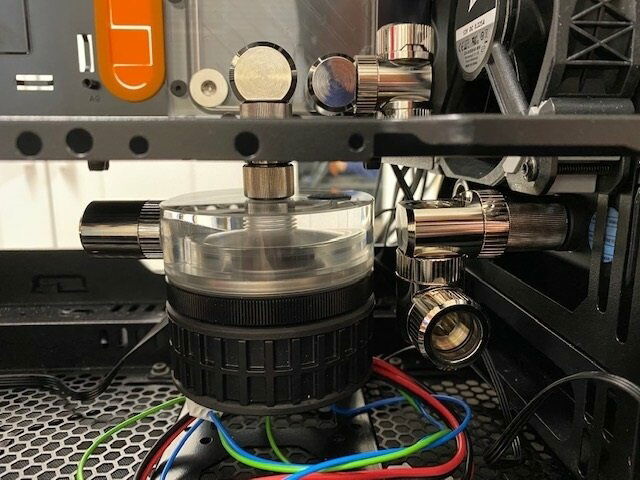

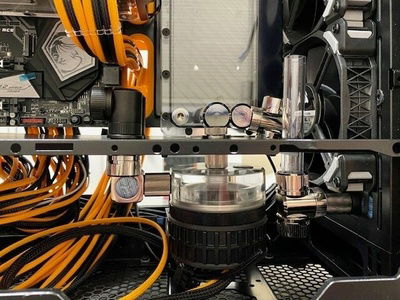

2/17 - Reservoir and radiators placement

3/1 - Crossing the mod chasm

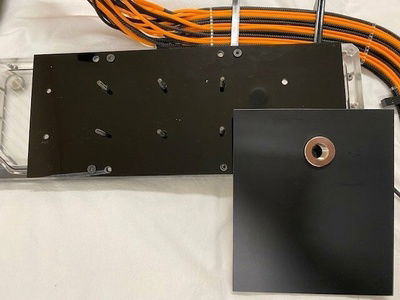

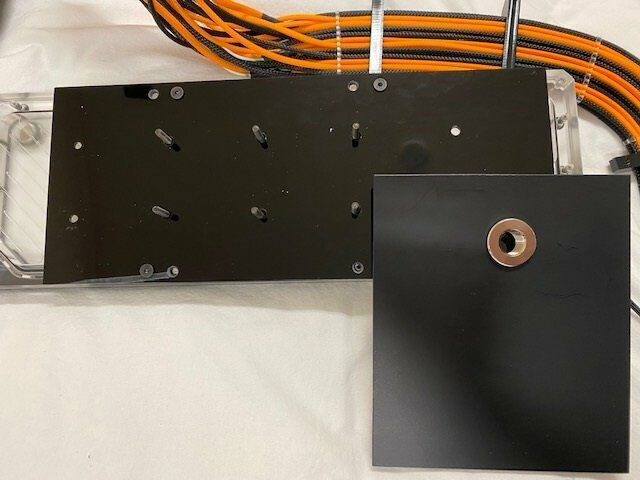

3/2 - Waterblocks and a speedbump

3/7 - More sleeving

3/11 - Installed All Pass Through Fittings

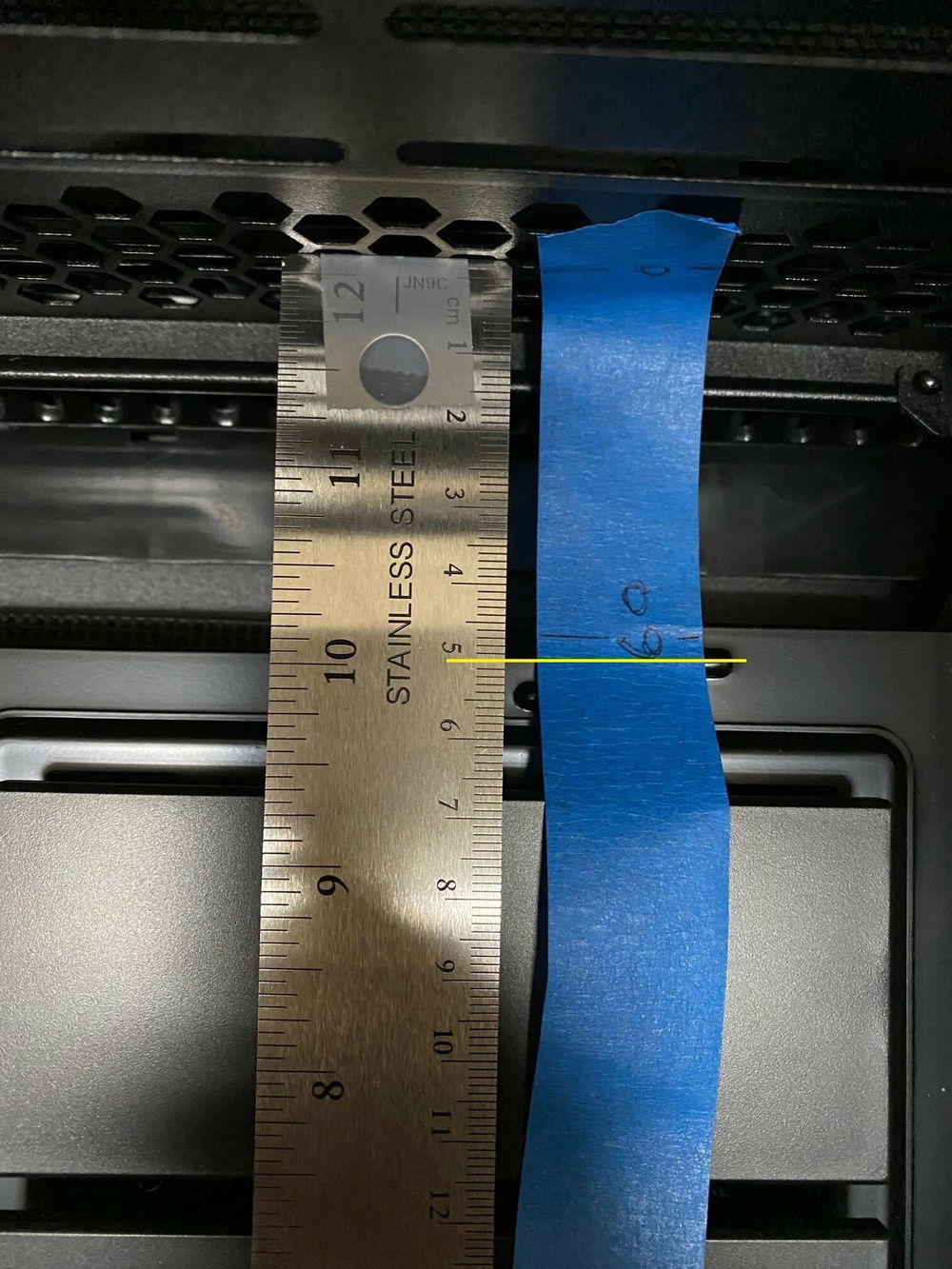

3/14 - Hardline It

3/22 - Completing The Build

More Power!!

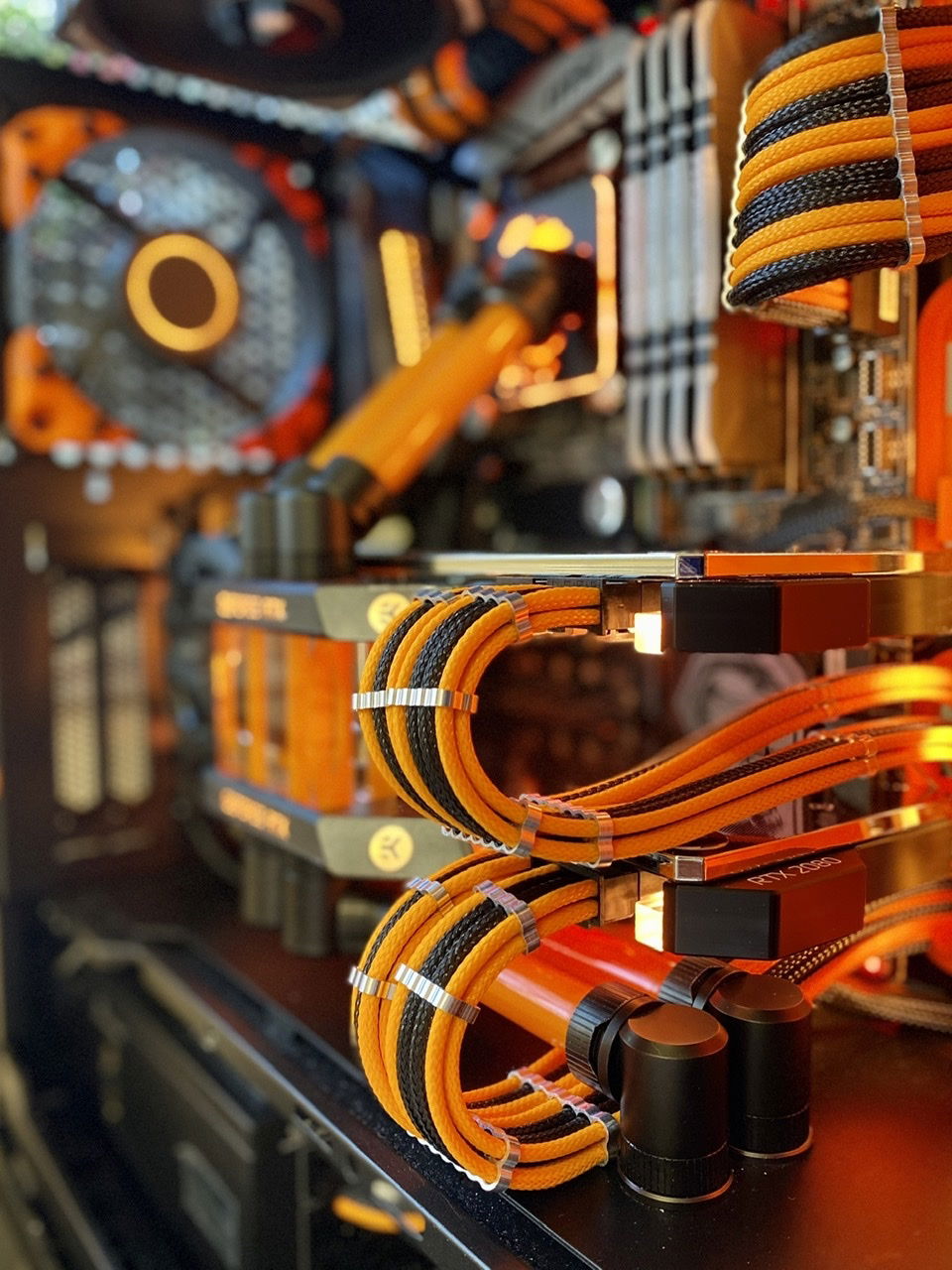

Second Graphics Card Cable

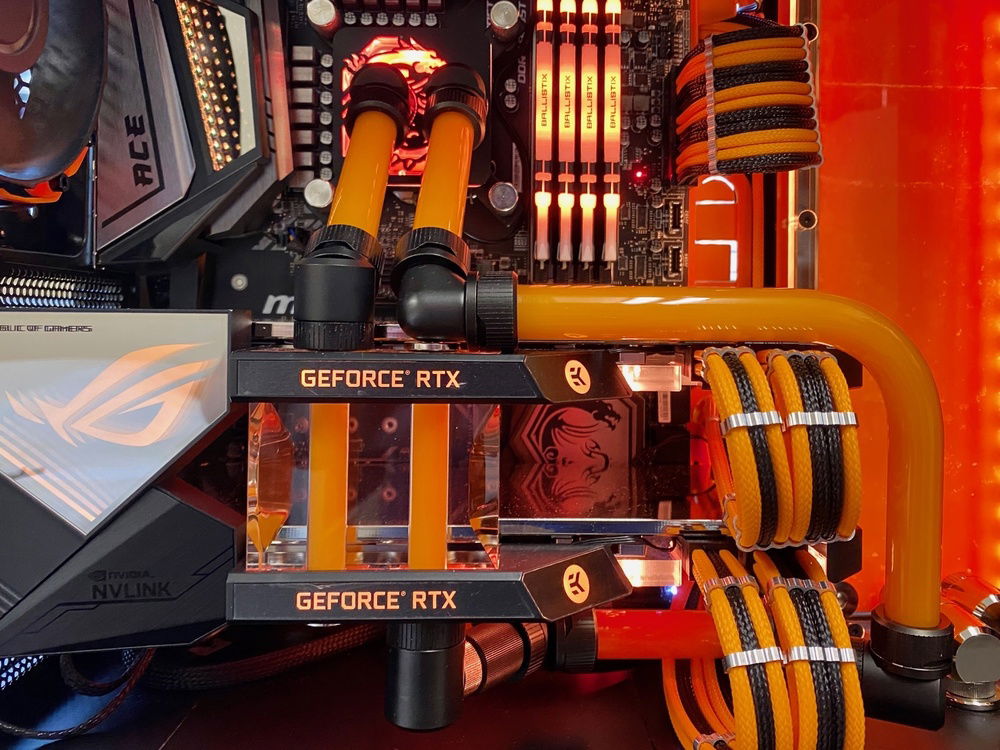

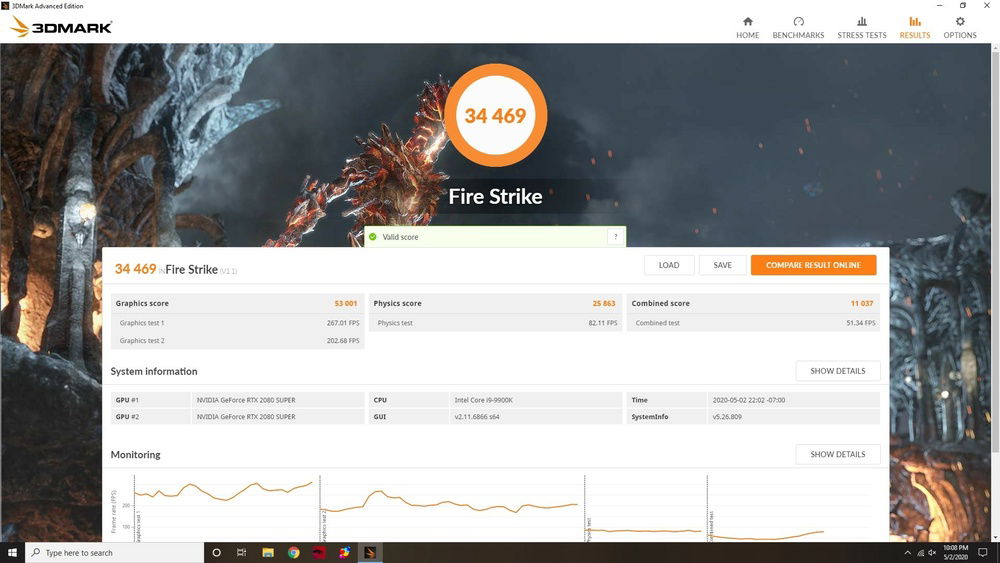

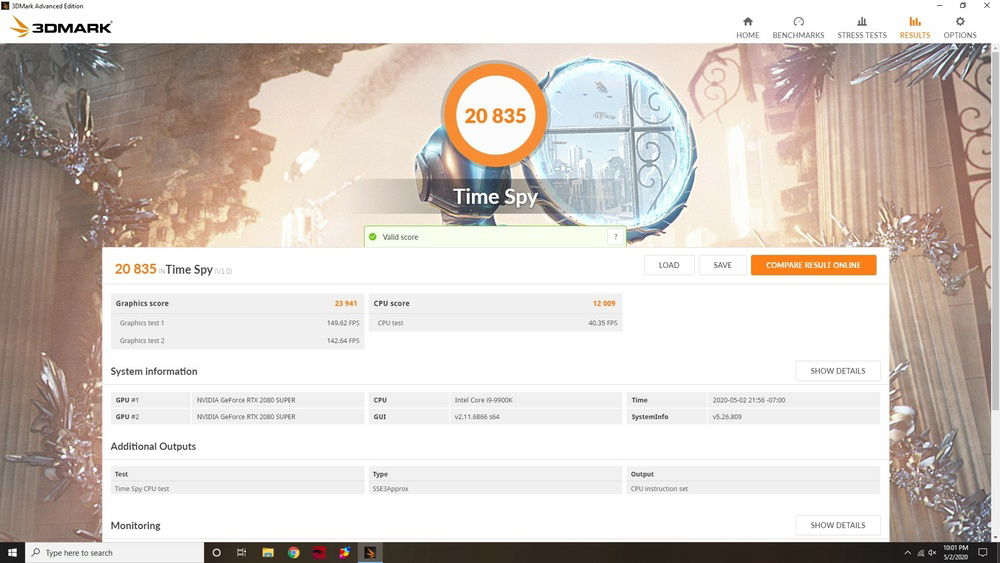

Complete dual graphics card

Serializing the CPU and GPUs waterblocks

Hardware

CPU

$ 449.00

Memory

$ 428.08

Graphics

$ 2,098.00

Case

$ 132.13

Case Fan

$ 378.00

Case Fan

$ 62.99

Cooling

$ 100.00

Cooling

$ 99.87

Cooling

$ 29.95

Cooling

$ 35.97

Cooling

$ 24.99

Cooling

$ 299.85

Cooling

$ 15.99

Cooling

$ 309.99

Cooling

$ 287.98

Cooling

$ 89.95

Cooling

$ 59.94

Cooling

$ 1,259.91

Cooling

$ 59.94

Cooling

$ 48.18

Cooling

$ 59.40

Cooling

$ 111.86

Cooling

$ 24.99

Cooling

$ 149.99

Cooling

$ 116.00

Accessories

$ 51.95

Accessories

$ 29.98

Accessories

$ 28.87

Accessories

$ 37.98

Estimated total value of this build:

$ 7,463.45

Approved by: