Pretty in Pink

This is what happens when nice watercooling equipment encounters an absolutely garbage-tier case. After some major modifications and adjustments, it's just proof you can make a great looking build in a case that may not have had anything close to watercooling in mind.

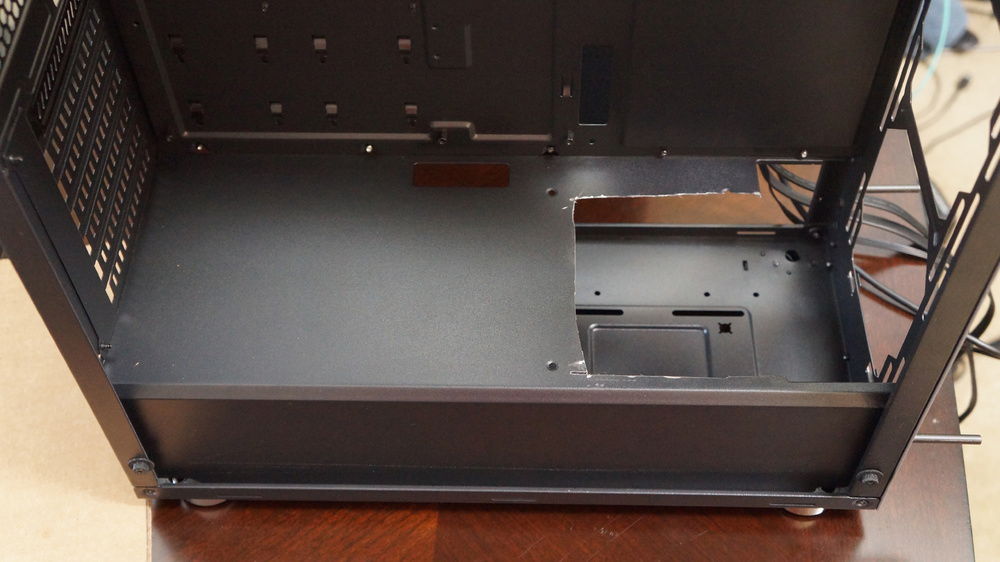

Case

Starting with the case, it's the Computer Upgrade King USA (CUKUSA) Stratos, a thin stainless steel case based on dimensions better suited in 2005. After some Dremel work and a complete rework of the front of the case to fix major airflow issues, it seems like you can actually fit a few radiators in there.

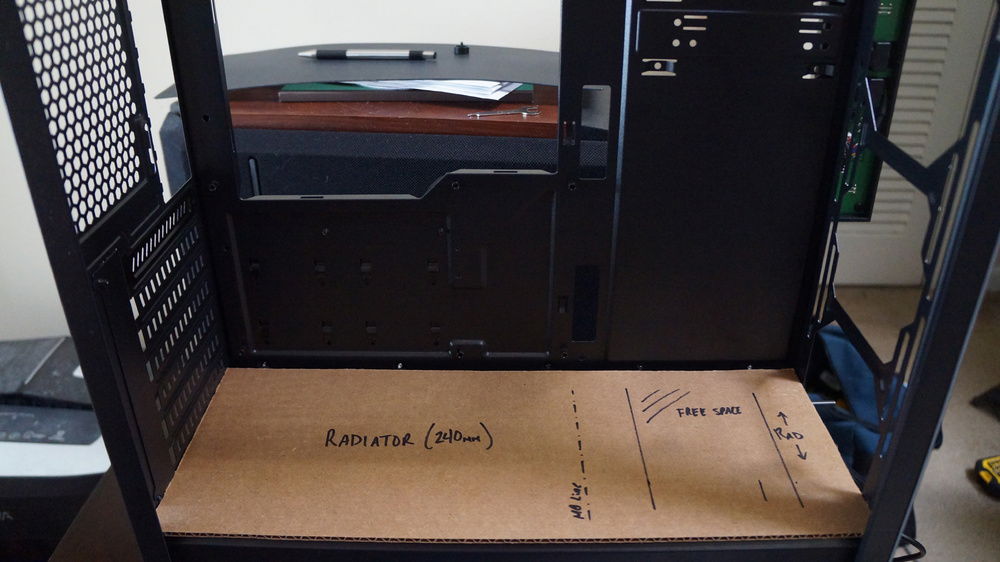

Watercooling

So, with the additional airflow, managed to get a 360mm and a 240mm radiator inside the case. They're not the thickest radiators, but they handled the load of both GPUs and the CPU without any real complaints.

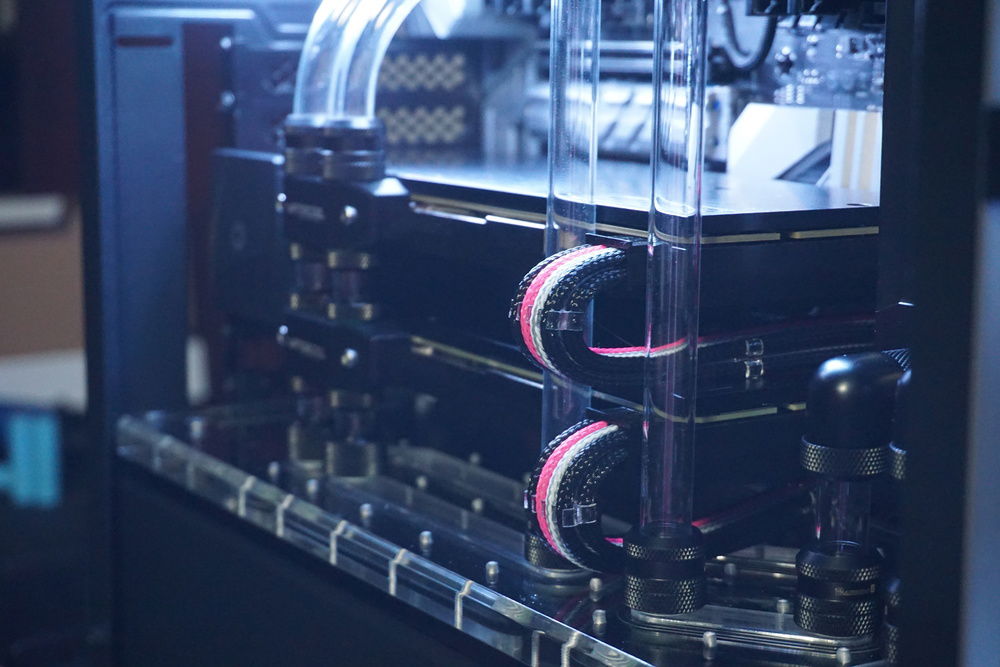

Lack of Space

While you can fit everything into the case, routing coolant was going to be a major issue. The distro plate took a bit to figure out, and was absolutely critical in connecting everything together. Without it, I don't think this build would've turned out as well. Also, learning a bit of Fusion 360 always helps with future projects.

Things of Note

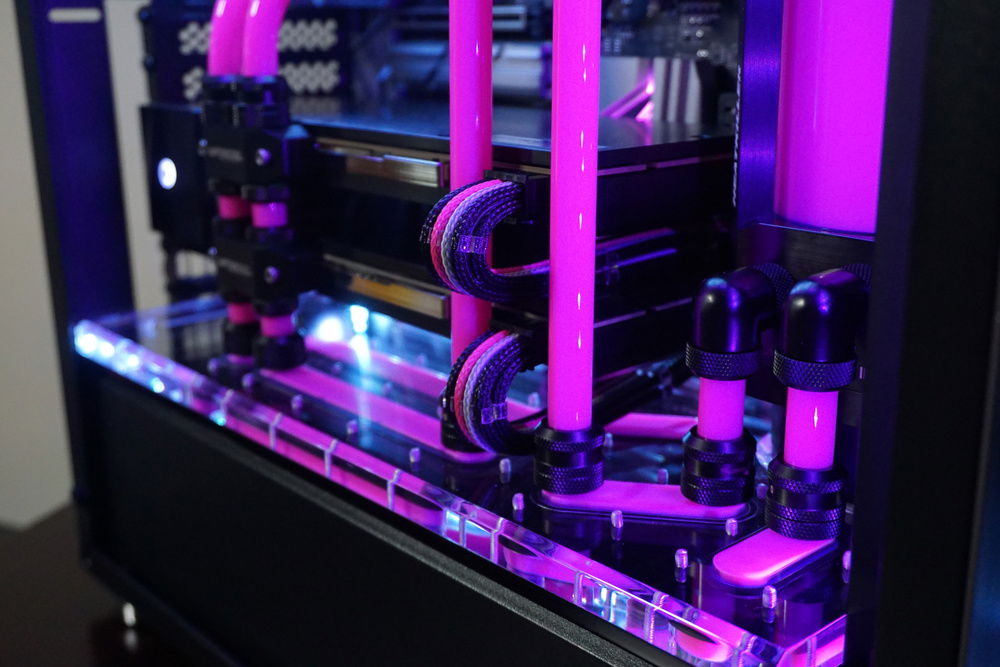

With the dual 1080s, the Threadripper CPU, and all of the Heatkiller blocks, there was a lot of black in the build. I figured that some white lighting and pink coolant would look absolutely great and would contrast the motherboard perfectly. The final touch was ensuring that some appropriately themed custom cables and then getting everything assembled.

The tubing is acrylic which tends to resist things like the collars of fittings biting into the tubing and leaving gouges. The overall loop layout is CPU/GPU/GPU all in parallel. It was a bit of a gamble, but the temperatures all worked out without issue.

Case

Starting with the case, it's the Computer Upgrade King USA (CUKUSA) Stratos, a thin stainless steel case based on dimensions better suited in 2005. After some Dremel work and a complete rework of the front of the case to fix major airflow issues, it seems like you can actually fit a few radiators in there.

Watercooling

So, with the additional airflow, managed to get a 360mm and a 240mm radiator inside the case. They're not the thickest radiators, but they handled the load of both GPUs and the CPU without any real complaints.

Lack of Space

While you can fit everything into the case, routing coolant was going to be a major issue. The distro plate took a bit to figure out, and was absolutely critical in connecting everything together. Without it, I don't think this build would've turned out as well. Also, learning a bit of Fusion 360 always helps with future projects.

Things of Note

With the dual 1080s, the Threadripper CPU, and all of the Heatkiller blocks, there was a lot of black in the build. I figured that some white lighting and pink coolant would look absolutely great and would contrast the motherboard perfectly. The final touch was ensuring that some appropriately themed custom cables and then getting everything assembled.

The tubing is acrylic which tends to resist things like the collars of fittings biting into the tubing and leaving gouges. The overall loop layout is CPU/GPU/GPU all in parallel. It was a bit of a gamble, but the temperatures all worked out without issue.

Color(s): Black Pink Silver

RGB Lighting? Yes

Theme: none

Cooling: Custom Liquid Cooling

Size: ATX

Type: General Build

Hardware

CPU

$ 850.00

Motherboard

$ 468.00

Memory

$ 160.00

Graphics

$ 299.00

Graphics

$ 299.00

PSU

$ 279.99

Case

Case Fan

$ 39.61

Cooling

$ 209.06

Cooling

$ 33.12

Cooling

$ 159.99

Cooling

$ 159.99

Cooling

$ 196.00

Cooling

$ 145.29

Monitor

$ 592.95

Approved by: