Industrial 719 - WIP

Building a workstation/gaming rig.

Color(s): Black Gray

RGB Lighting? No

Theme: Industrial

Cooling: Custom Liquid Cooling

Size: E-ATX

Type: General Build

Build Updates

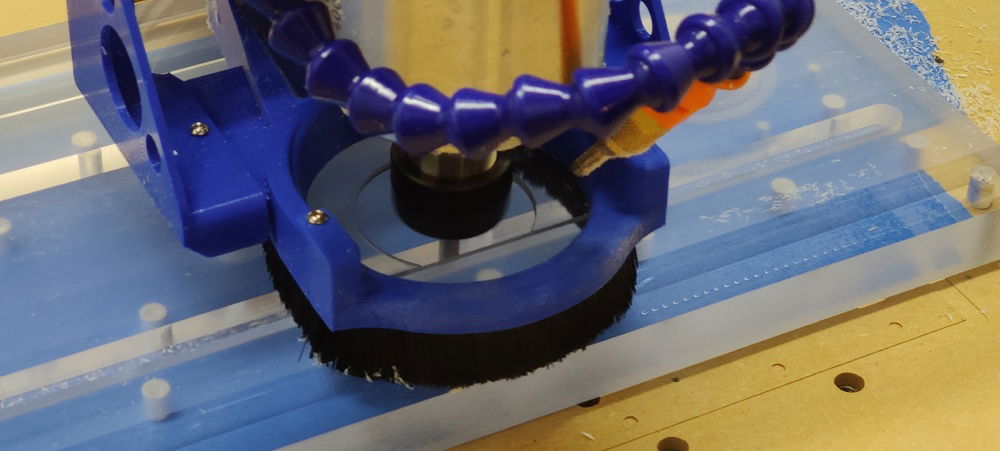

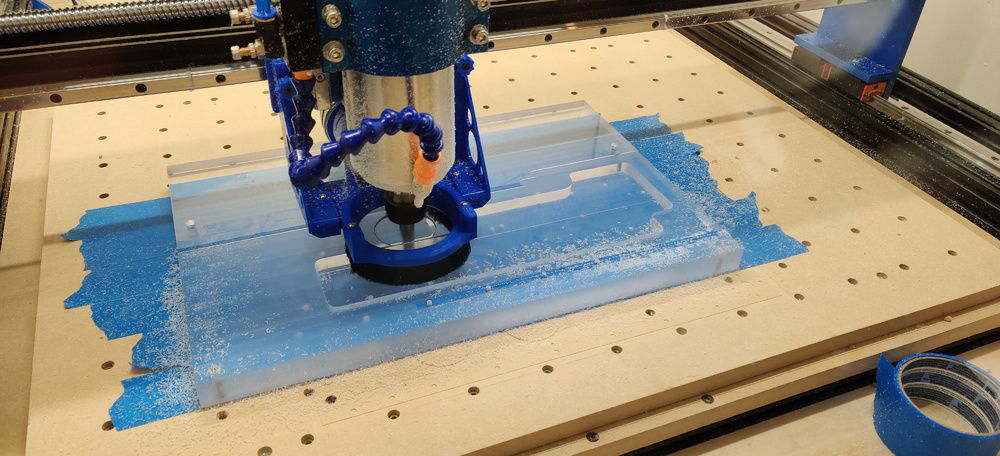

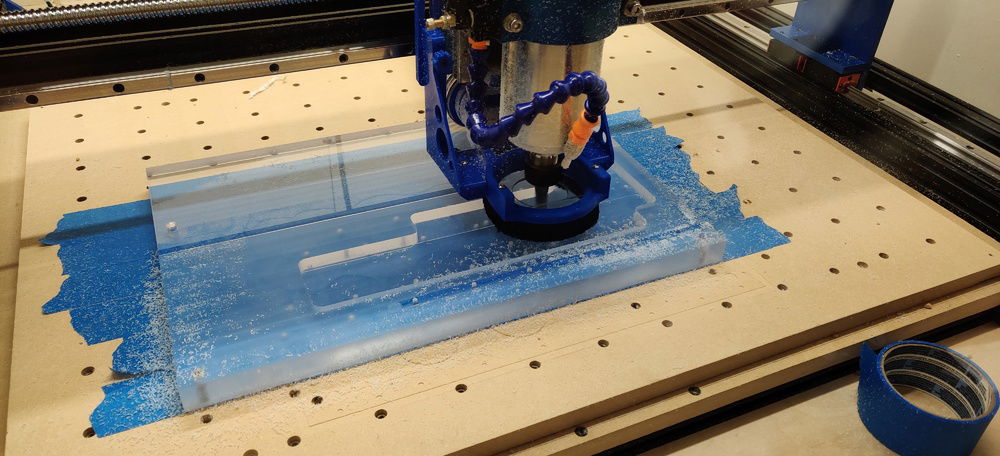

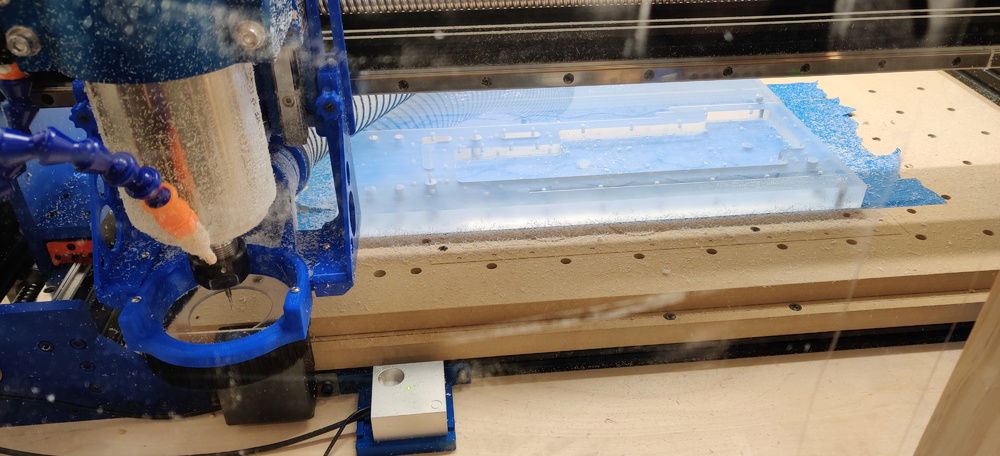

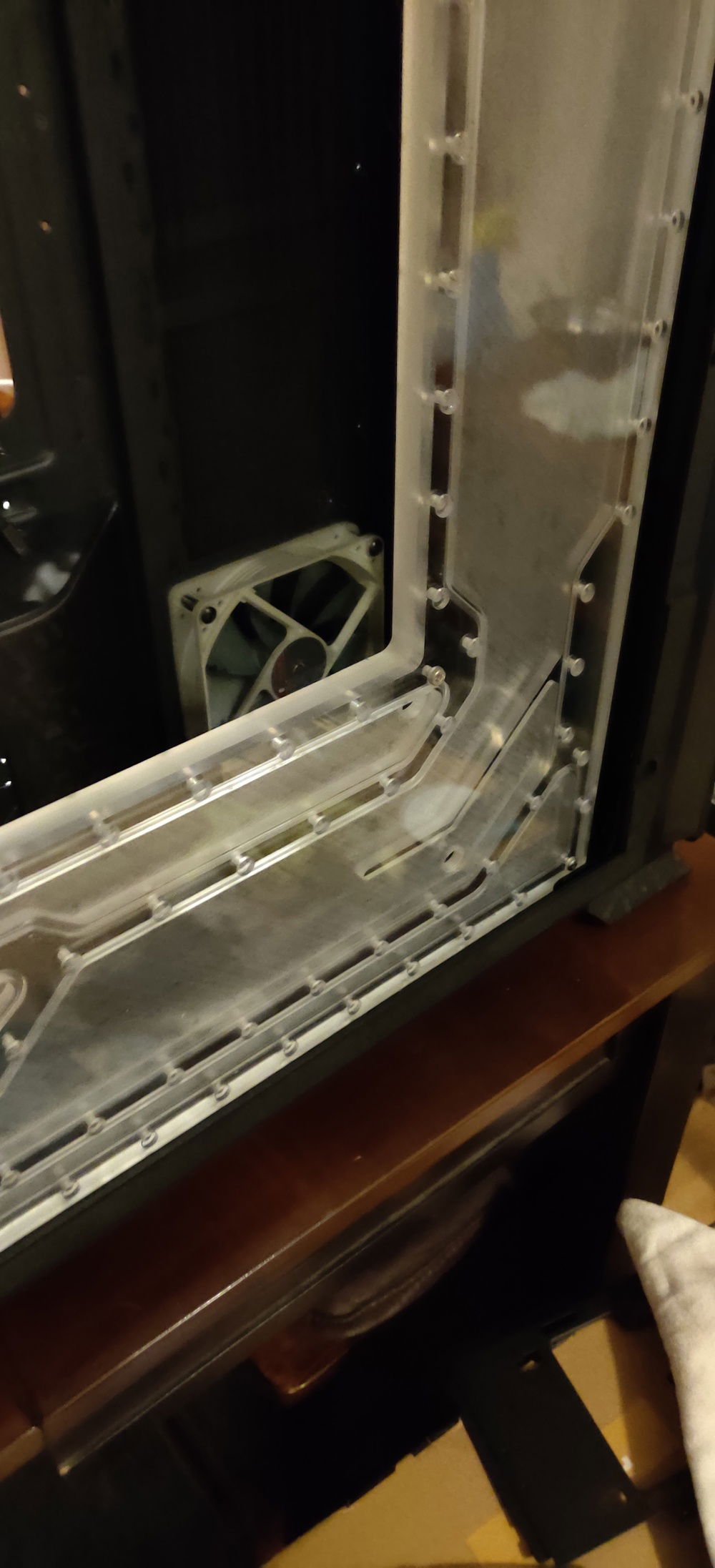

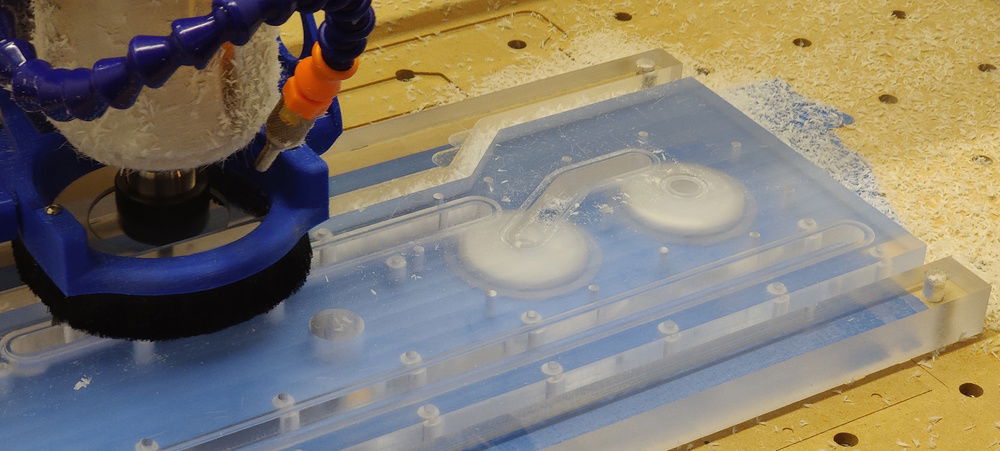

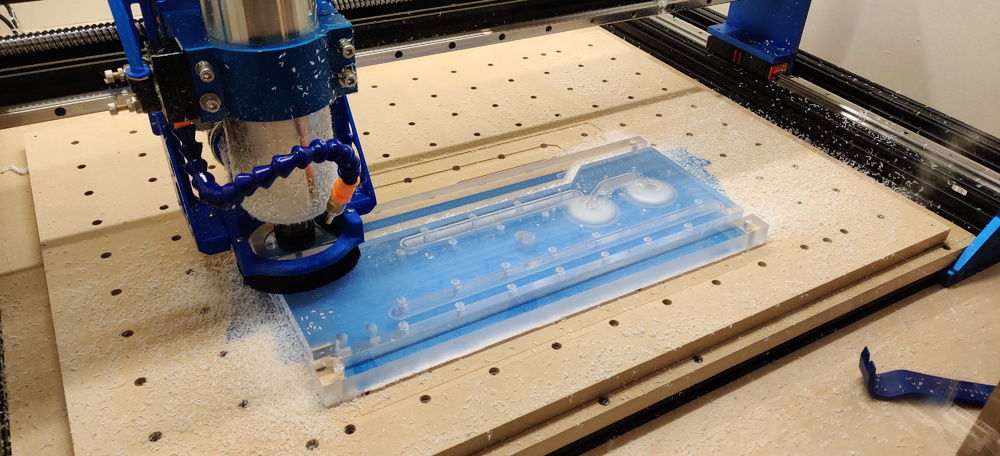

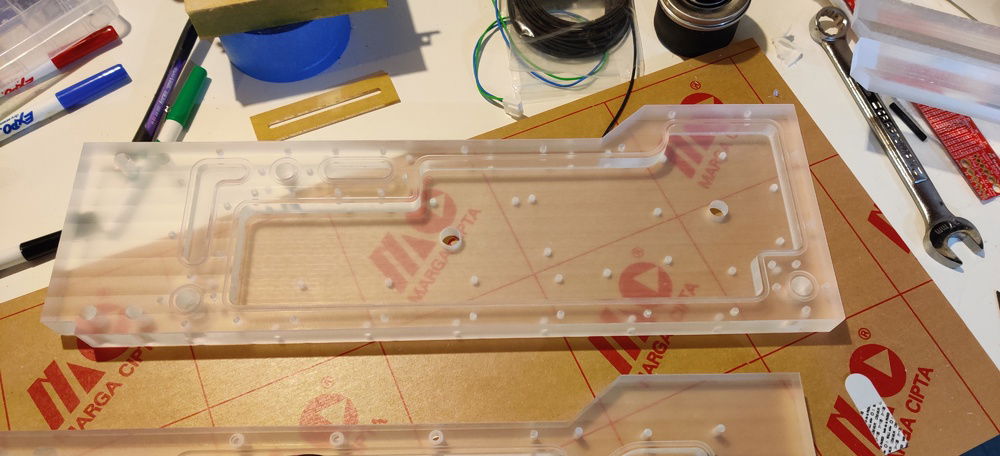

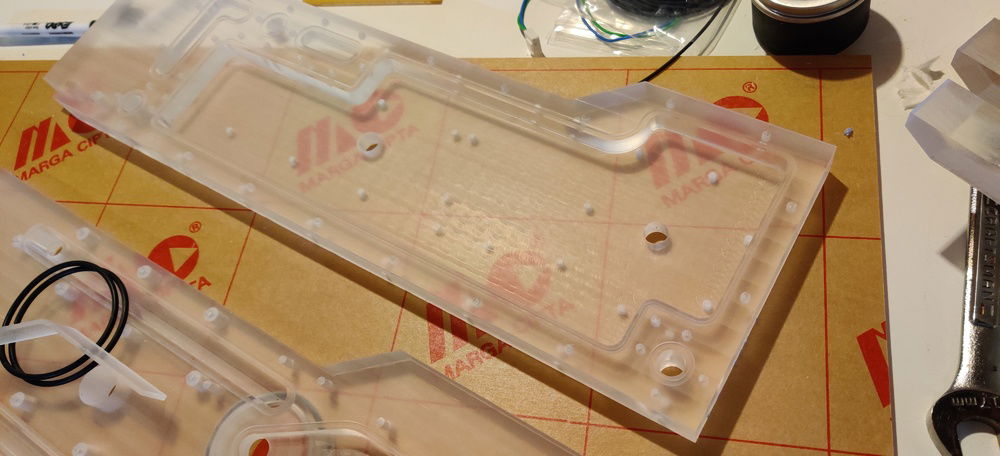

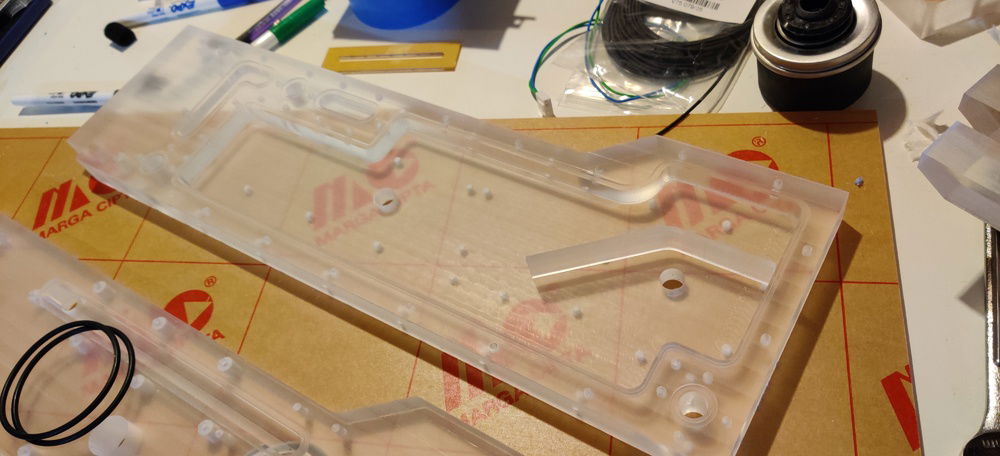

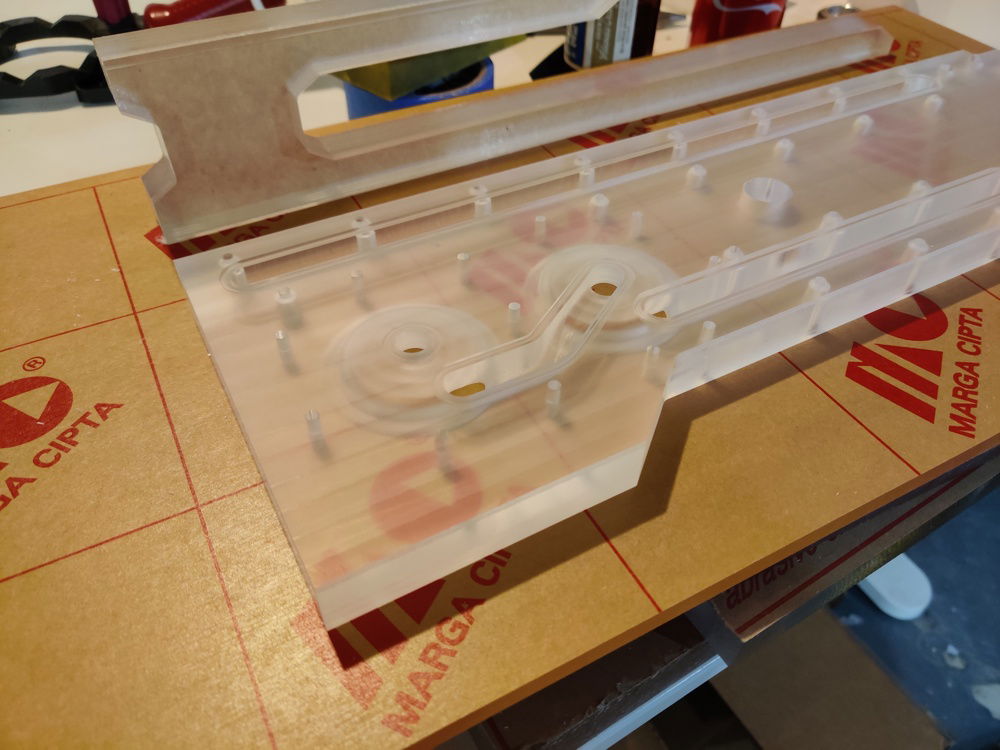

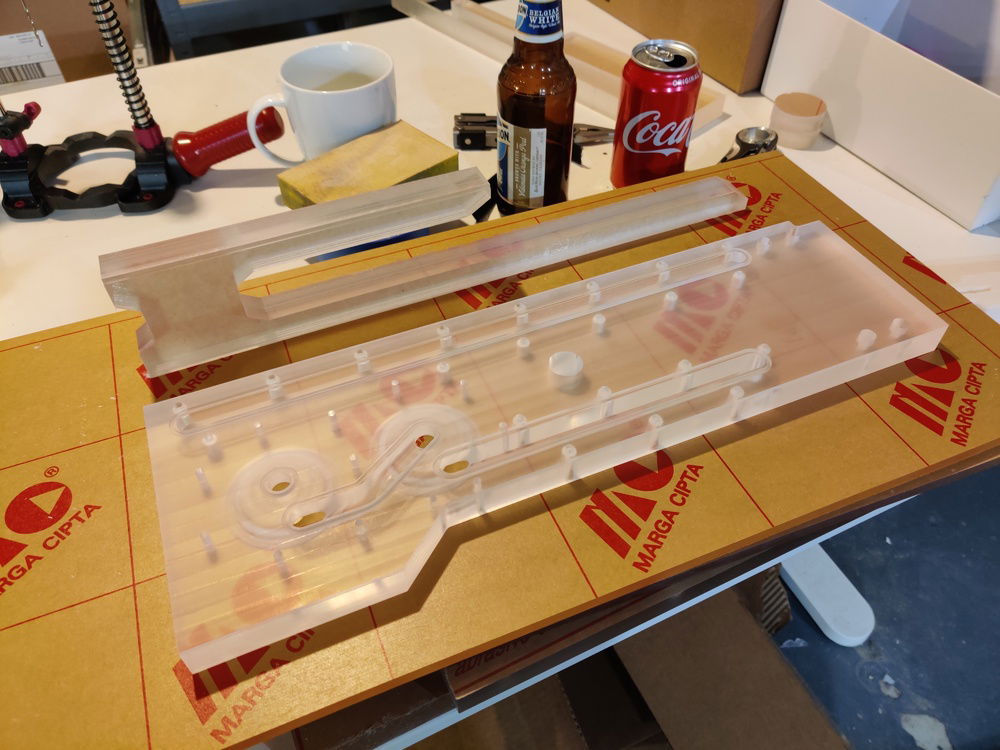

Bottom Distro Plate done!

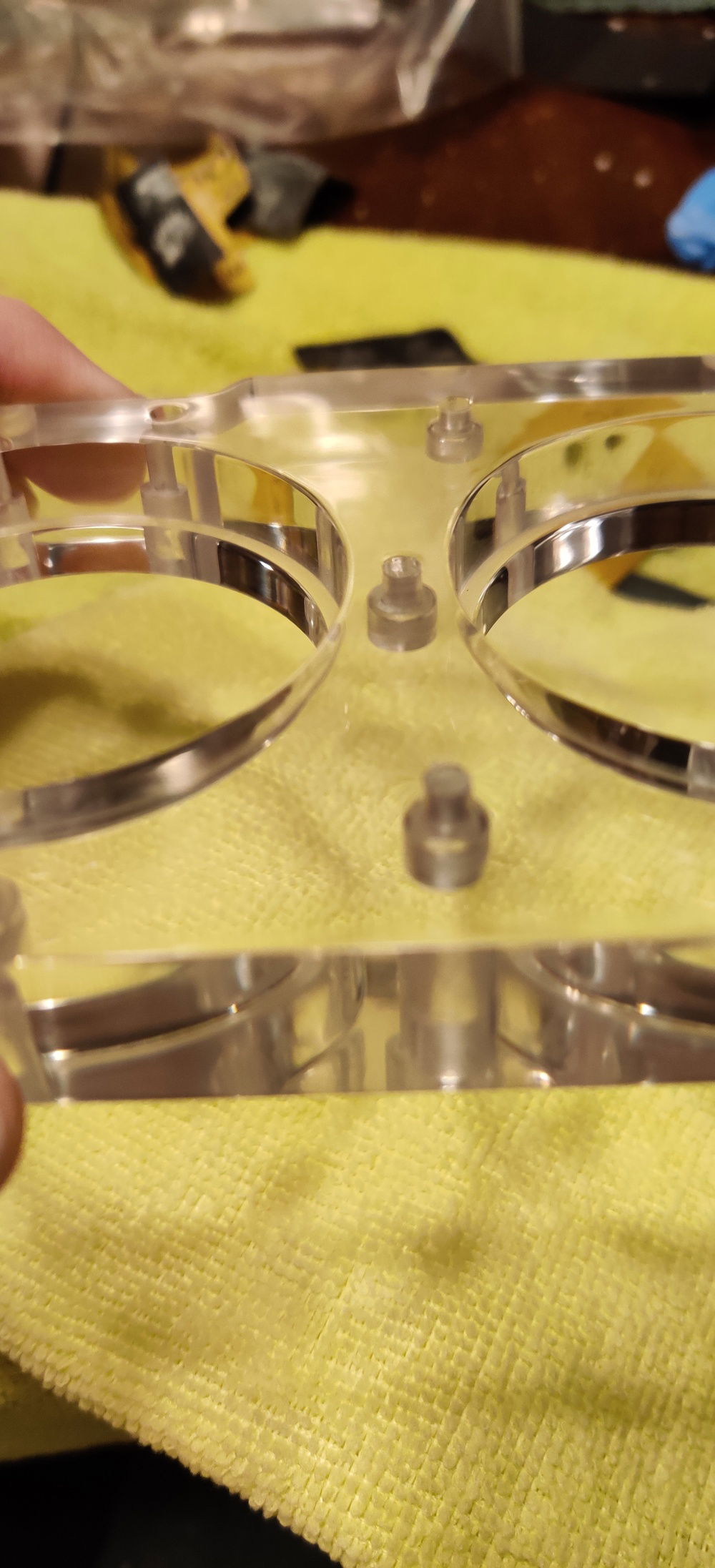

Mid Plate / Reservoir Plate Done!

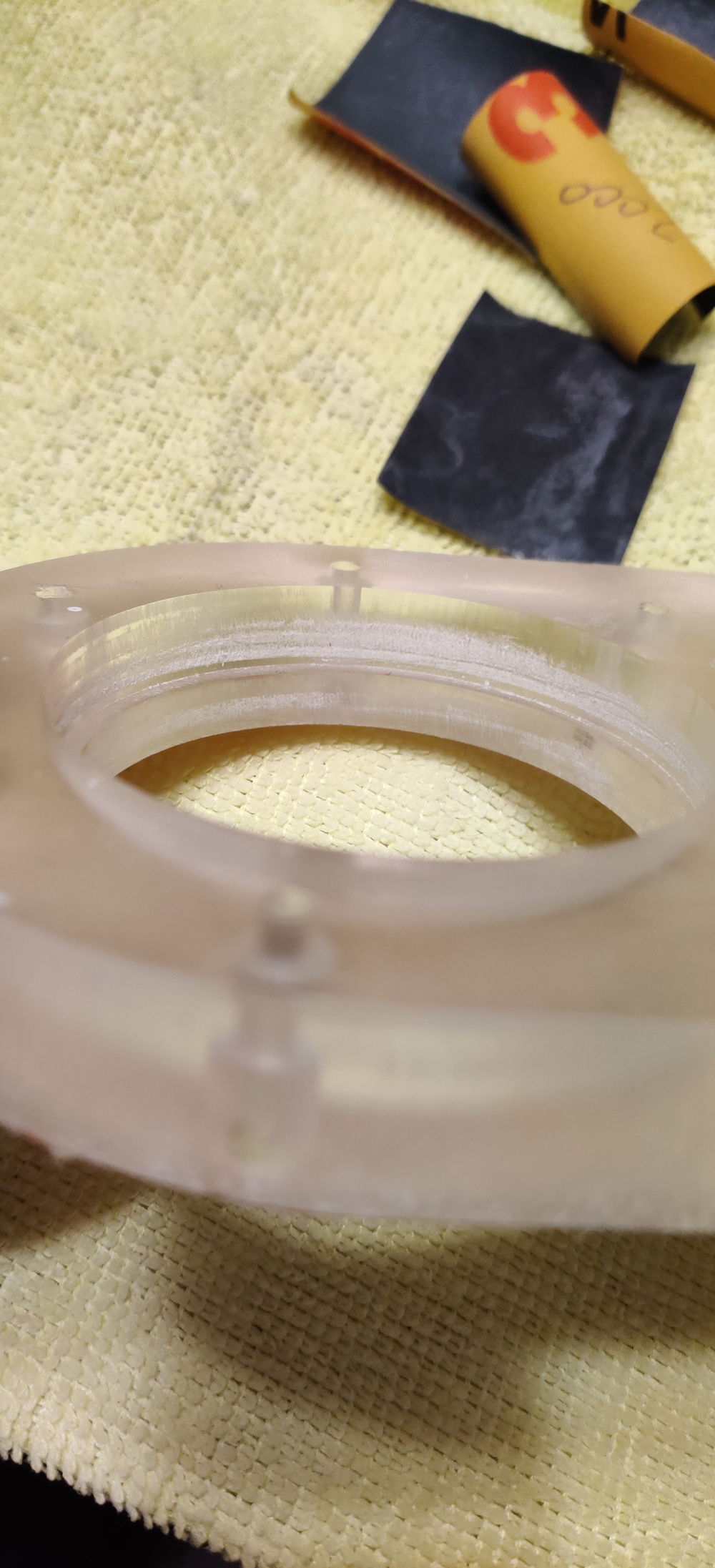

Sanding Hell

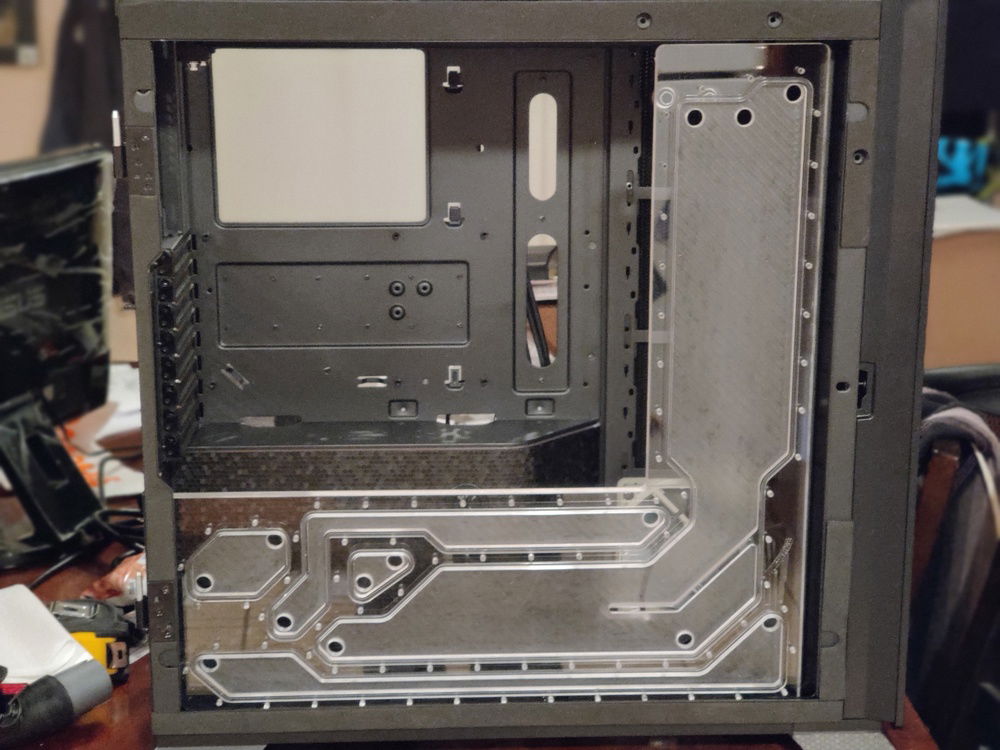

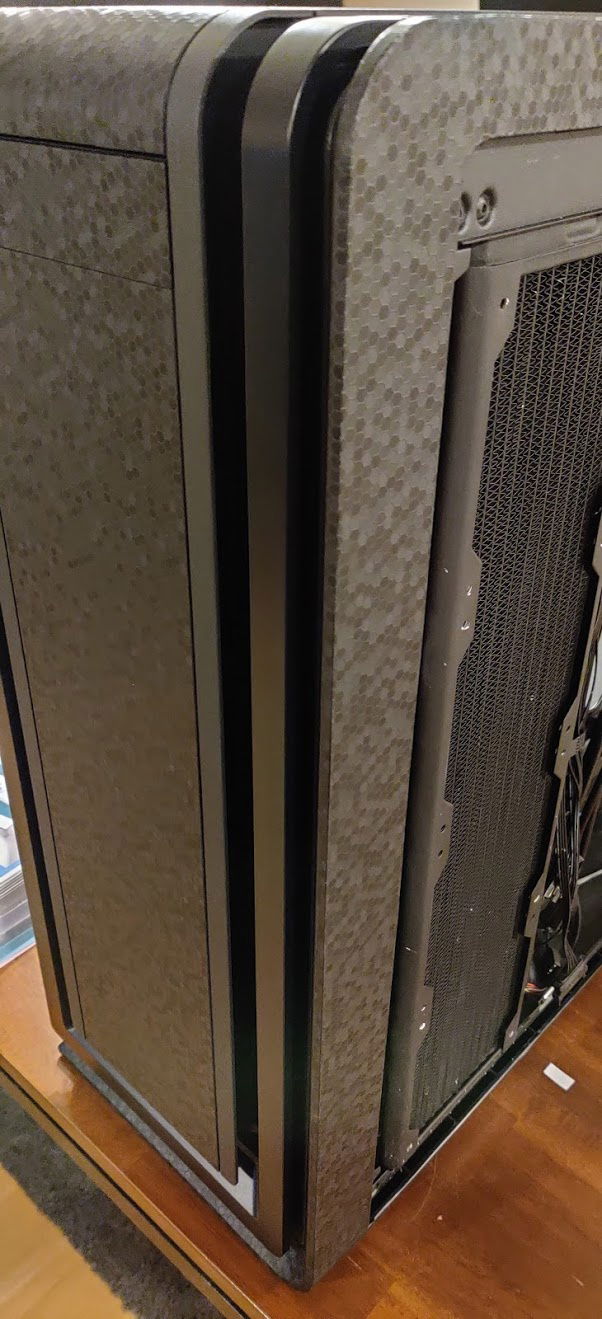

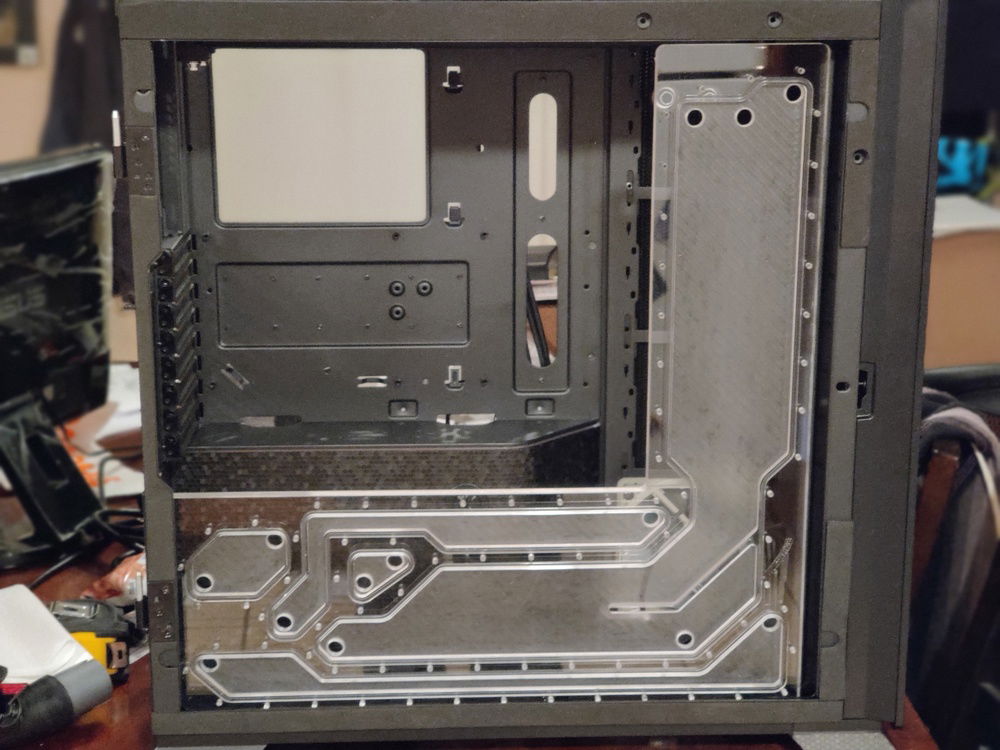

Case Work

Social Distancing for the win!

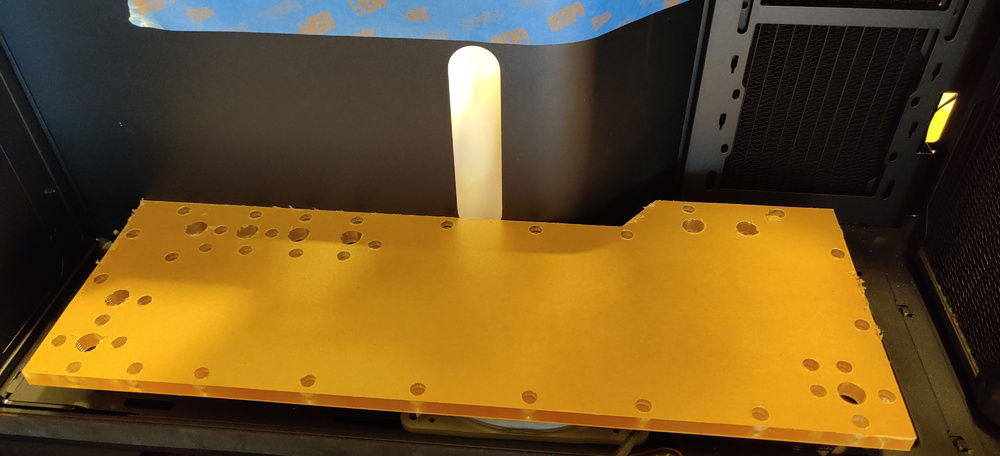

First Test Plate is done!

Acrylic and Bits!

Parts are in!

A year in the building.

Hardware

CPU

Motherboard

$ 888.74

Memory

Graphics

Case

Case Fan

$ 174.35

Case Fan

$ 17.95

Cooling

$ 197.98

Cooling

$ 34.29

Cooling

Cooling

Cooling

Cooling

Approved by: