Frozen Steam

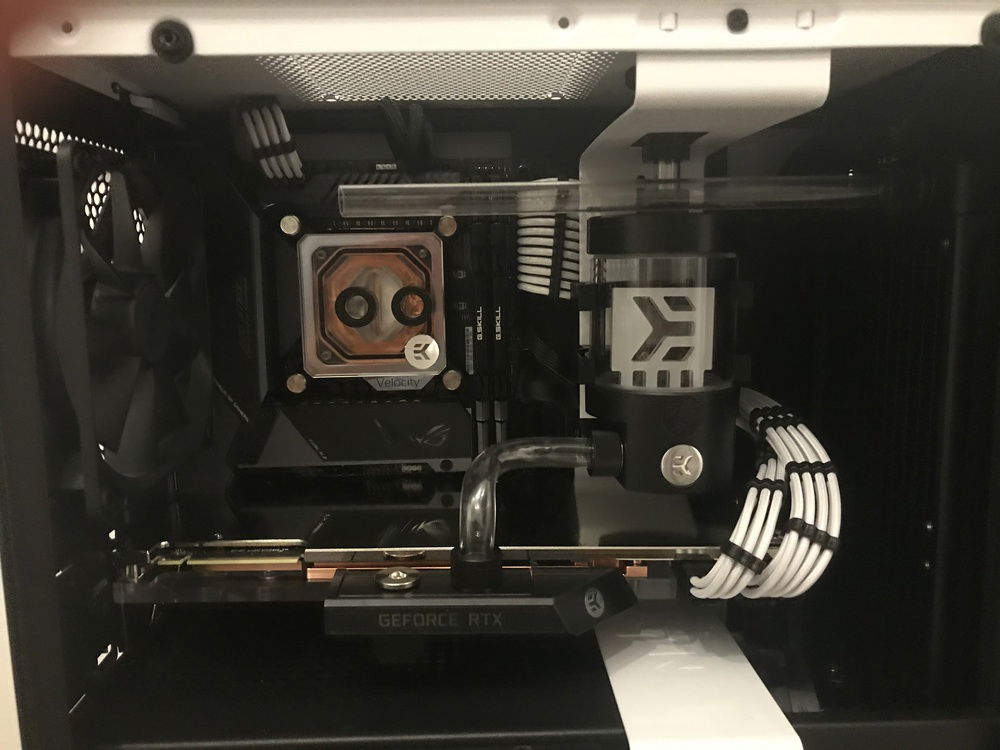

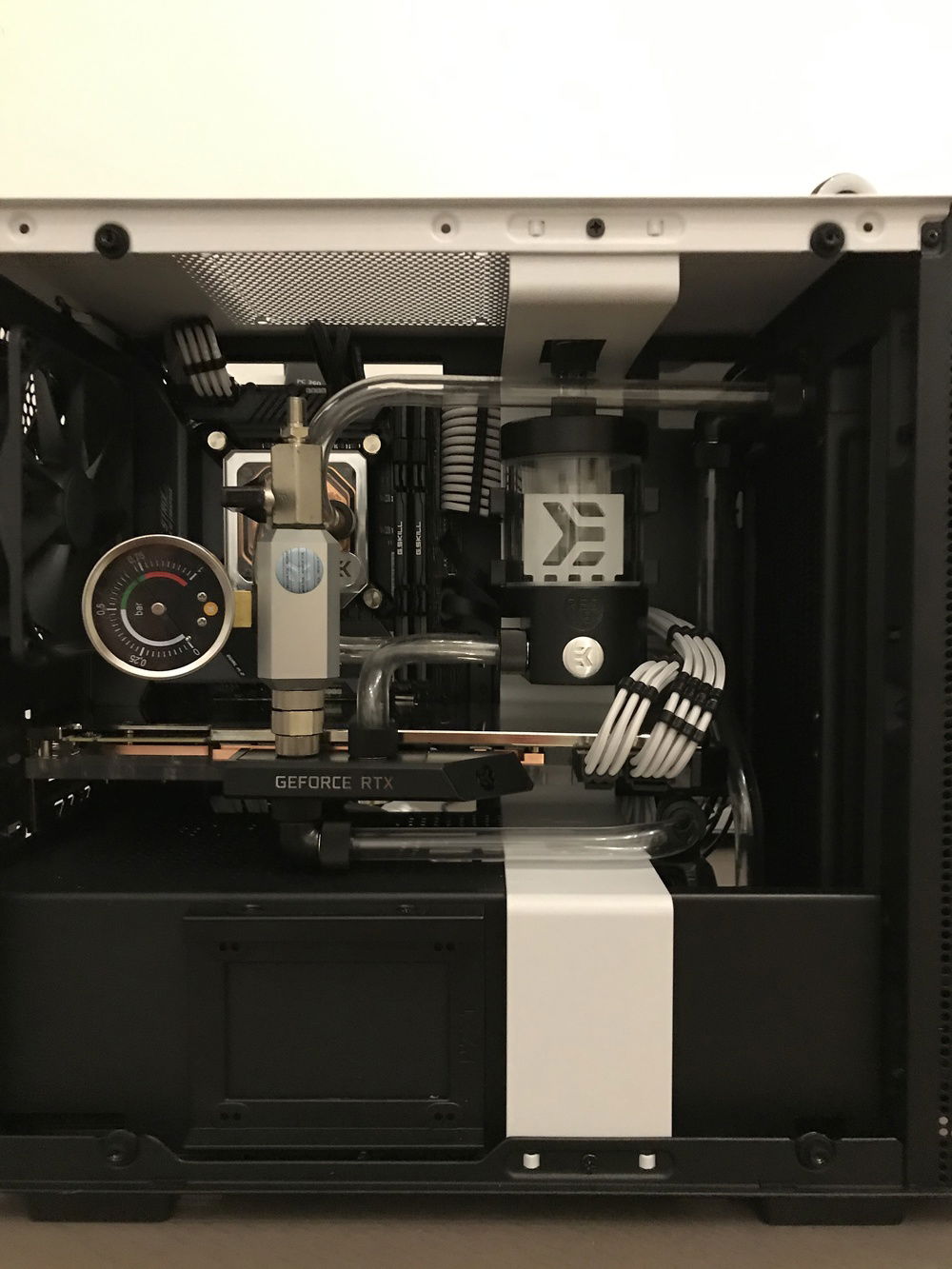

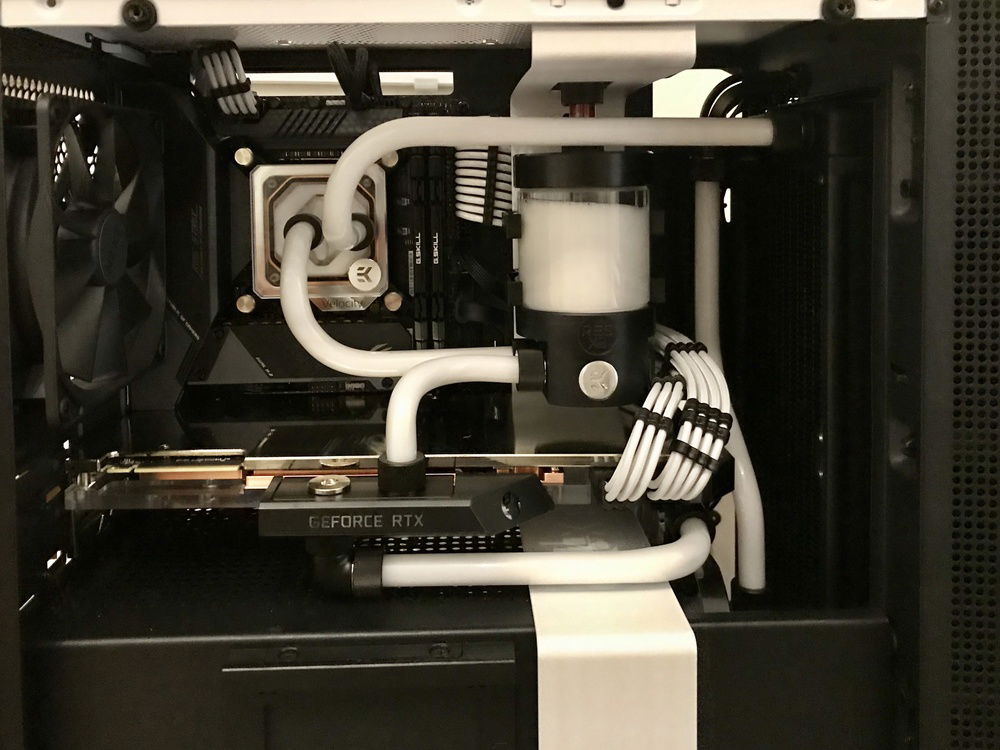

The design principal of this build was to combine high performance and maximum silence in the smallest space as possible.

Basic setting:

Dreamed of a water-cooled gaming system since I became 16 years old (now I am more then twice that old), now the pandemic was the perfect time to work on this.

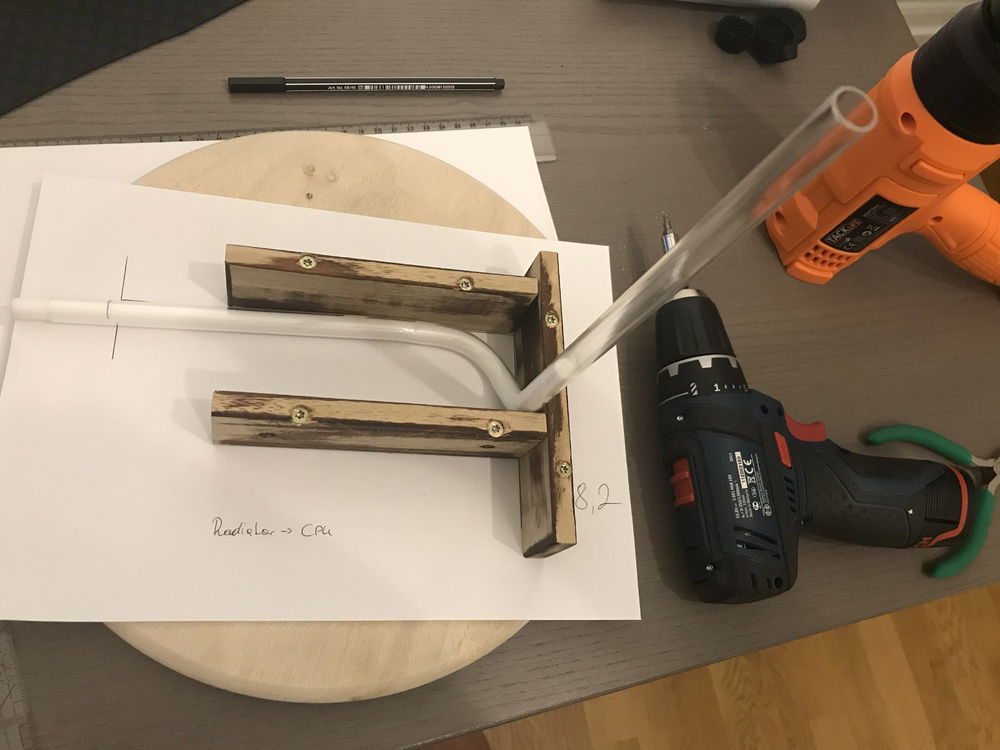

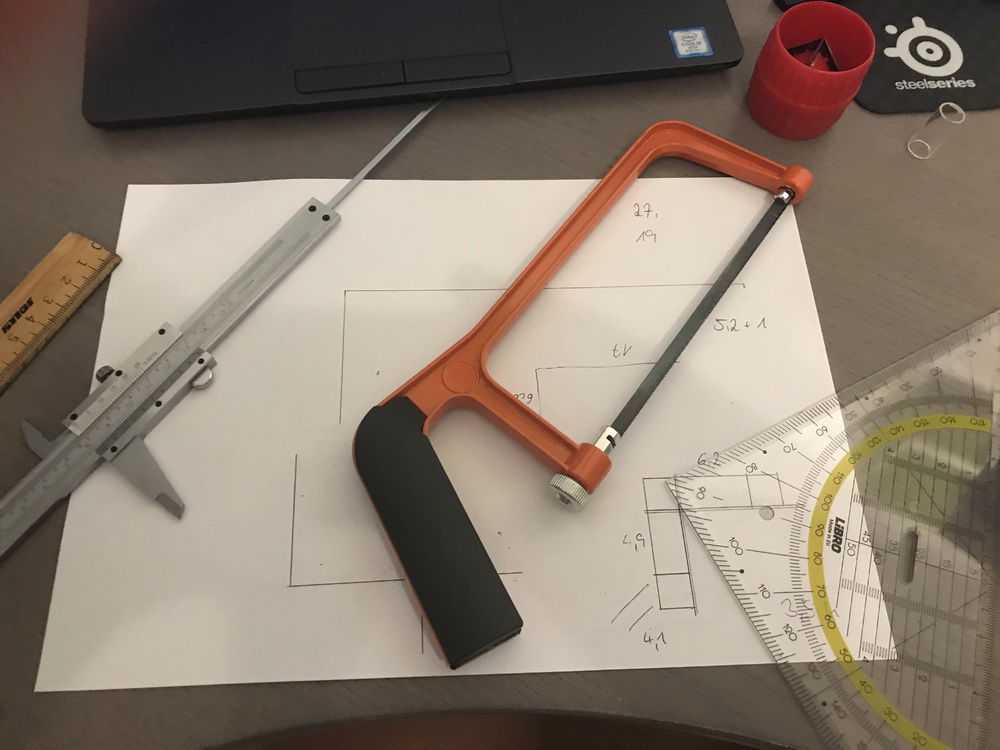

Although I build all my previous PCs myself, this was the first one with liquid cooling and I decided to go for hard tubing as I simply like it more than soft tubing.

Anyway as bending hard tubes is not that easy at first time, I was during this journey sometimes not sure if this was maybe too ambitious.

Finally I spend around 25 hours on this build and guess will stay with liquid cooling in future as well.

Basic setting:

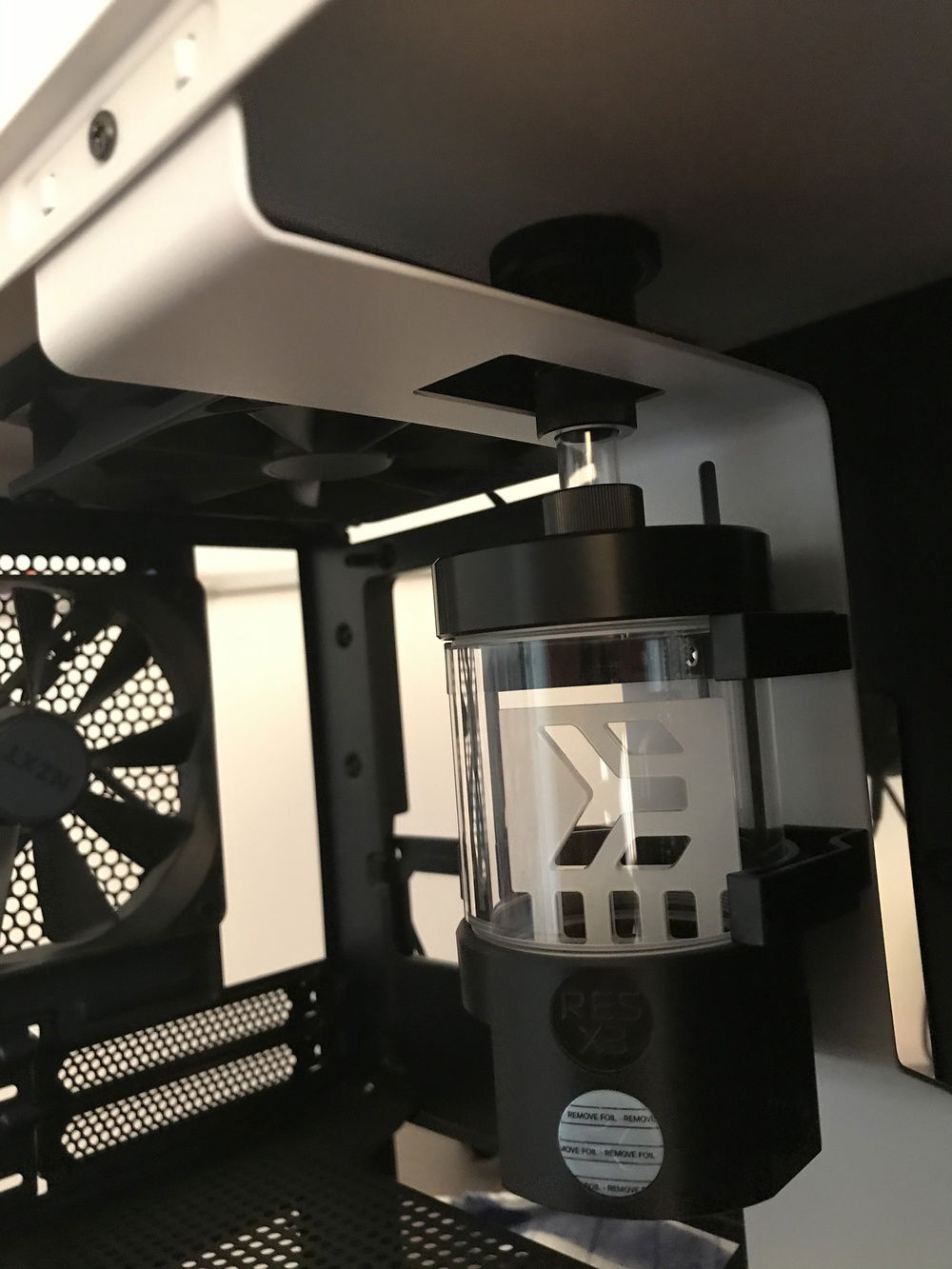

- Hide pump behind buttom panel

- Fill port on top of the case

- Drain port bottom of case

Dreamed of a water-cooled gaming system since I became 16 years old (now I am more then twice that old), now the pandemic was the perfect time to work on this.

Although I build all my previous PCs myself, this was the first one with liquid cooling and I decided to go for hard tubing as I simply like it more than soft tubing.

Anyway as bending hard tubes is not that easy at first time, I was during this journey sometimes not sure if this was maybe too ambitious.

Finally I spend around 25 hours on this build and guess will stay with liquid cooling in future as well.

Color(s): Black White

RGB Lighting? Yes

Theme: Steampunk

Cooling: Custom Liquid Cooling

Size: Mini-ITX

Type: General Build

Contests

This build participated in 2 contests.

| Rank | Contest | Date |

|---|---|---|

| #440 | EK 10K Challenge | ended |

| #165 | SFFPC meets builds.gg Contest | ended |

Hardware

CPU

$ 299.00

Motherboard

$ 499.00

Memory

$ 239.40

Graphics

$ 699.00

Storage

$ 171.23

Case

$ 69.99

Case Fan

$ 56.00

Cooling

$ 186.04

Cooling

$ 90.77

Cooling

$ 222.18

Cooling

$ 149.99

Keyboard

$ 143.37

Mouse

$ 40.97

Estimated total value of this build:

$ 2,860.62

Approved by: