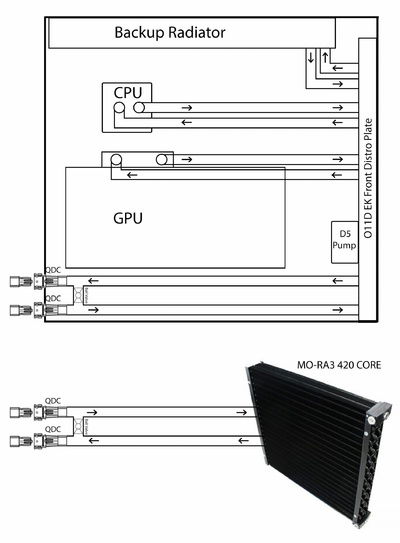

The Design

Initially the plan was to buy off the shelf components and hook them them up without must additional work. Acrylic tubes would be used and it would be a quick project.

Enter the water block for the video card: EVGA's Kingpin Hydro Copper. I first lucked out on buying the extremely rare and exclusive Kingpin 3090 Video card. Then fast forward to April 2021 I lucked out once again and scored the ultra exclusive pure copper water block for it. When I first laid my eyes on this beautiful piece of 8mm thick copper and heavy acrylic water block I decided to build something very special. I had to incorporate copper in the build. Copper is a gorgeous metal and there had to be a build idea to showcase that brilliance.

Computer Specifications

Case Lian Li O11 XL

CPU AMD Ryzen 9 5900x 12 Core 24 Thread 4.8GHz

Motherboard Asus Crosshair VIII X570 Dark Hero

Video Card EVGA Kingpin Nvidia RTX 3090 Hybrid

Fans Exhaust 3x Noctua NF-A12x15 PWM chromax.Black.swap @ 20% Speed Static

Fans Intake 2x Noctua NF-S12A PWM chromax.black.swap @ 20% Speed Static

Cables Custom Sleeved cables from Mainframe Customs

Boot Drive Samsung 980 Pro 1 TB NVME Gen 4

Storage Drive XPG SX8200 Pro 2 TB NVME Gen 3

PSU Seasonic Prime 1300W Plus Gold

Monitor Alienware AW3418DW 34" Ultra Wide 3440x1440

Water Cooling Components

CPU

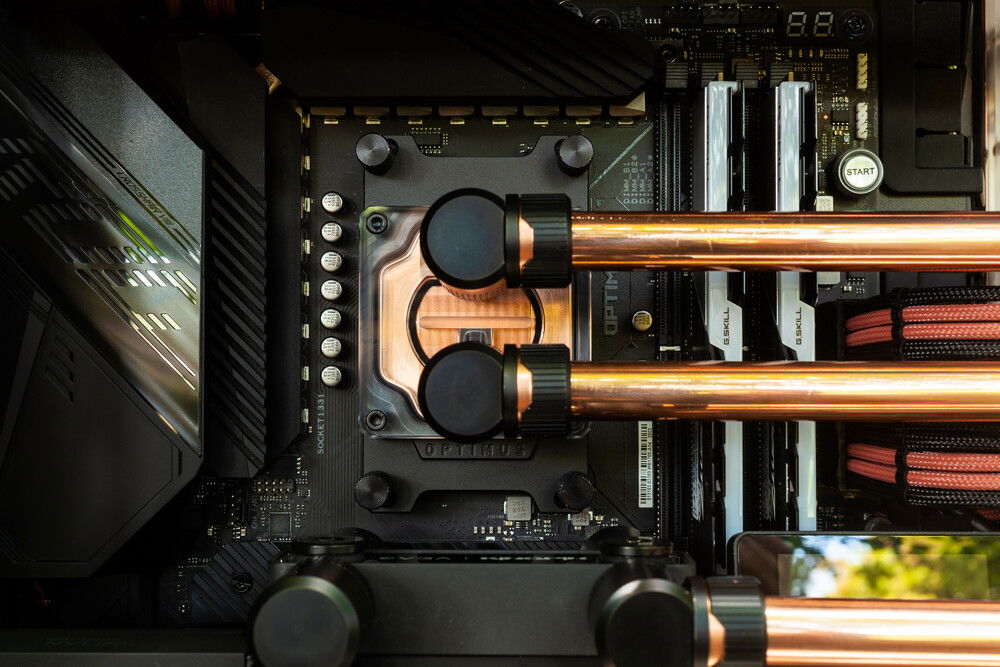

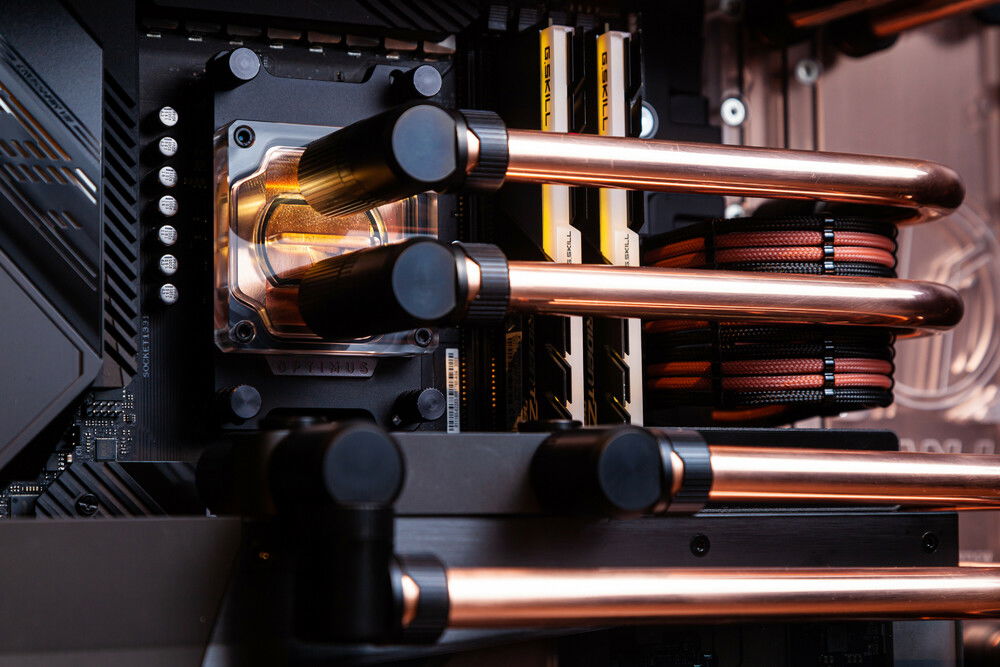

Optimus Foundation Block Acrylic + Black Aluminum / Raw Copper

EK Quantum Torque Rotary 90 x2

EK Quantum Torque MF Extender Static MF 28mm

EK-Quantum Torque Rotary Offset 3mm x2

EK Quantum HDC with custom painted accent rings x4

GPU

Kingpin Hydro Copper Block

MP5 Backplate Cooler (For rear VRAM)

EK Quantum Torque Rotary 90 x5

EK Quantum HDC with custom painted accent rings x7

EK Quantum Torque Rotary Offset 7mm

Bitspower 60° Rotary MF

EK Classic 90° FF x2

Internal Radiator

EK Coolstream PE

EK Quantum Torque Extender Static MF 14mm

Bykski B-TFC-CS OLED Flowmeter

Internal backup pump

EK D5 PWM G2 Pump

EK Quantum Inertia D5 Body, Digital RGB

EK Quantum Torque Rotary Offset 14mm

EK Quantum HDC with custom painted accent rings x4

Distribution Plate

Barrow LLO11-SDB-D5

Tubing

EK ZMT 12 meters (for external connection)

12x Barrow TGWG-14 14mm Copper pre-bent 90° rigid tube – Chrome, Reverse electroplated, sanded, buffed using jeweler's red polishing compound

External Radiator

Alphacool NexXxoS XT45 Full Copper 1260mm Super Nova Radiator

4x Thermaltake Technology Pure Series 200mm fan

Barrow SPG40A-X, 18W PWM Combination Pump

Bitspower inline filter

Coolant

EK Cryofuel Clear Concentrate x2 Biocide and Anti-Corrosion additive

Distilled water 2.5L

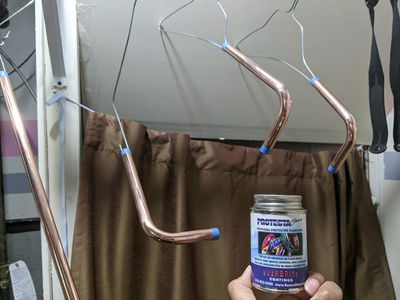

The Tubing

Perhaps the most striking part of this build is the tubing. There was a lot of research and work required to get it in it's final finish. Barrow TGWG-14 Pre bent 90 degree chrome tubing was used. Copper in it's raw finish quickly rusts to an undesirable brown color which is the reason why all computer specific tubing will have paint or electroplating on it. Mine came in chrome and looked like below:

The research began on how to cleanly strip the chrome plating off this otherwise pure copper tubing. The cleanest way would be to get it electrically stripped. I contacted some local electroplating shops and landed on

https://www.platinghouse.com/. Upon explaining my project, Mark at the shop was extremely friendly and accommodating. Simply based on the initial interaction I was positive this would be the place to support. He even walked me through the whole process at the shop.

The tubing was wrapped in electric wire and dunked it in a huge bath of electrolyte and after a couple of minutes I was greeted with a beautiful (but rough) pure copper tube. After reverse electroplating, the finish was very rough and had marks from the process. Mark and his team was kind enough to do an initial buffing using a heavy cut polishing compound and show me the process from start to end.

The final mirror shine polish was up to me so I bought a 80 ply unstitched buffing pad for my bench grinder along with red jeweler's polish. Note that all tubes were measured and cut before this process. Video below shows how I did the final polish.

Here is a closer shot of buffing. It is a time consuming but pretty fun process

Finished product

Next step is to seal the tubes using two coats of Everbrite's ProtectaClear solution. The ends were masked 10mm as it would be inserted into the water cooling fittings.

This is what happens to a unprotected copper tube after about one week Right: Polished and sealed Left: Polished and left unsealed.

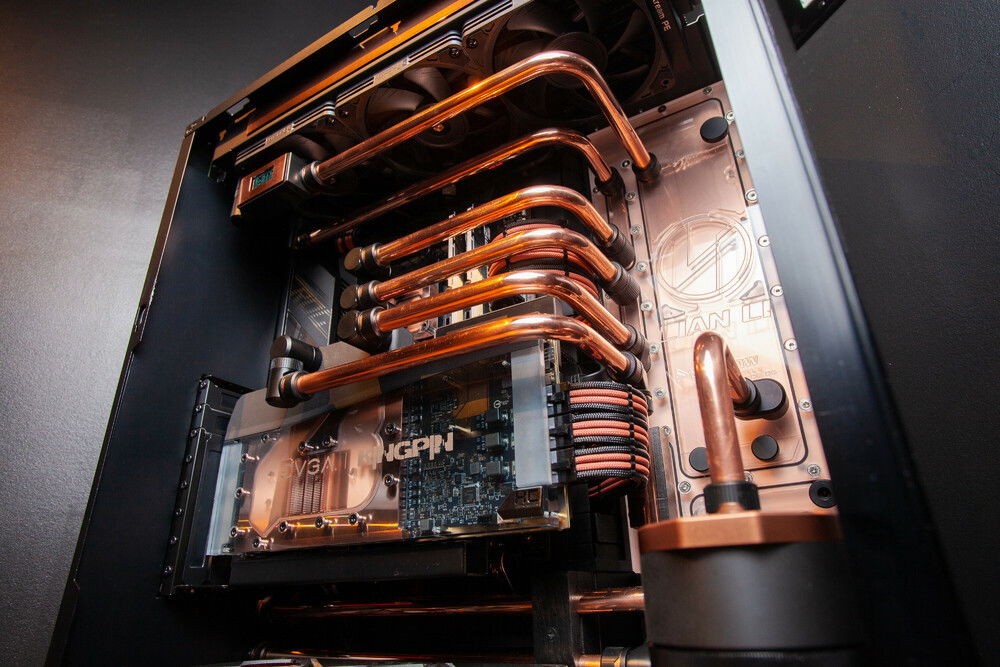

External Unit

The beast behind majority of the cooling is this Alphacool NexXxoS XT45 Full Copper 1260mm Super Nova Radiator. It is the biggest computer specific radiator I have seen. Most people use the MORA-3 but I decided to get this instead as it was cheaper. This unit does not have to look aesthetically pleasing because it will be living in a different room outside the office. The problem with this radiator is that there are no mounting options so I had to get creative and design something myself. It started with mounting aluminum L brackets to the radiator.

This contraption was born to hold the pump reservoir combo and the radiator in a small package.

Vertical piece of wood is there for mounting the external pump and reservoir combo

Painted black and assembled. There is a bitspower inline filter in there to catch any contaminants in the loop

ZMT Galore

To have the external cooling unit in another room I used 12 meters of 10/16mm EK ZMT (6 meter one way). ZMT stands for Zero Maintenance Tubing made of EPDM. As the name suggests it is popular for being the most stable rubber which does not release plasticizers or other contaminants in a water cooling loop.

This soft tubing was neatly run under the table and through the drywall into next room

Installed into the external cooling unit. Absolute chungus.

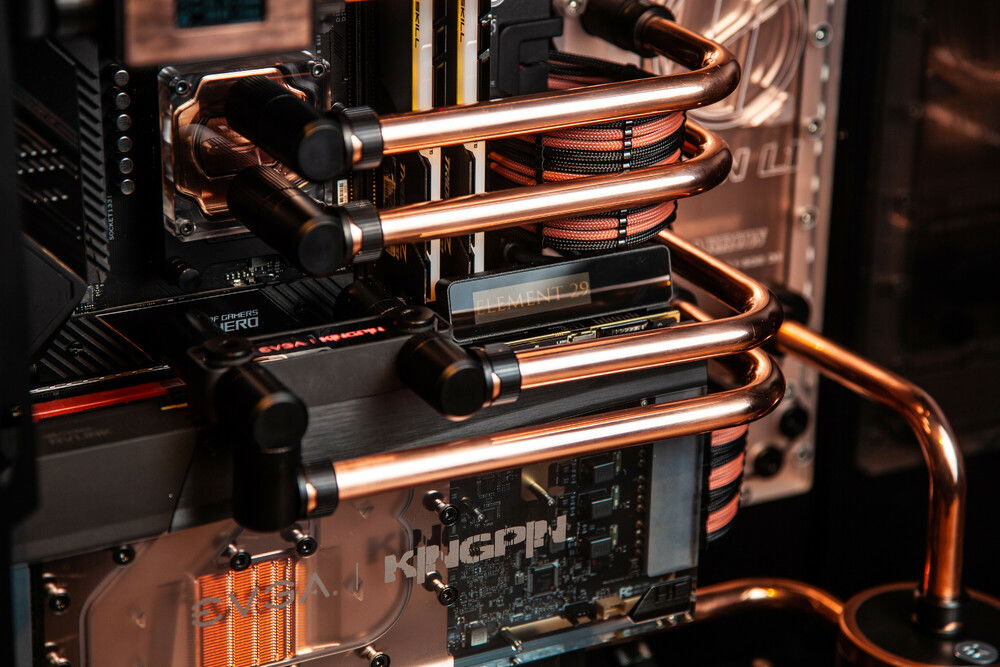

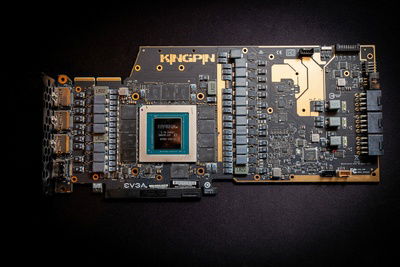

GPU Assembly

The EVGA Kingpin Nvidia RTX 3090 is Nvidia's latest and greatest offering for the gaming segment. The GA102-300 core has 28.3 Billion transistors packed in the die. This particular model "Kingpin" is the fastest model available in North America and has custom PCB that is designed to push the 3090 chip to it's limits in terms of overclocking. More details here:

https://www.evga.com/products/product.aspx?pn=24G-P5-3998-KR

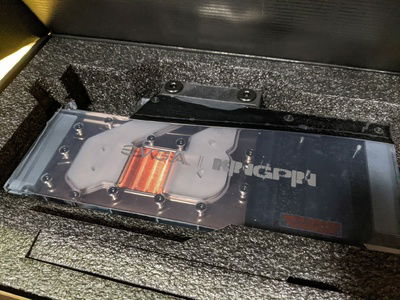

These cards can consume close to 500W under full load and generate a tremendous amount of heat. To take that I was able to get a hold of their custom made water block

Love at first sight. It weighs 3 LB and consists of a thick machined 8mm copper plate screwed to a heavy acrylic top. Absolute chonker.

The 3090 cards come with 24GB of Micron's blazing fast GDDR6x RAM. Half of the memory is located on the rear side of the card which can hit 110°C when left to cool using a conventional passively cooled backplate. This called for a custom made backplate cooling block made in the UK called "MP5 BPC" (backplate cooler).

Loads of thermal pad was used on the rear VRAM to siphon heat from the PCB into this MP5 block. Measurements were done by tracing a photocopy of the PCB to get a full coverage of all rear components. Thermalright Extreme Odyssey 12.8 W/mK pads were used due to their excellent heat transferring capability

The thickness of the various surface mounted components was measured

Memory Modules 1 mm

SMD Capacitors 2.00 mm

MLC Capacitors 1.24 mm

Based on these numbers, the appropriate thermal pad thickness was chosen

Here is the card fully assembled in this water cooling pancake

MP5 BPC installed in parallel

That is 6 LB in total just for the video card. Holy moly.

Results

All this work for what? Proof is in the puddings. Have a look at the temps below

Computer Temperature

Ambient Temp 22°C

Idle Coolant Temp 24°C

Coolant Flow Rate 2 L/min (120 L/h)

Overclocked 3090 @ +100 MHz Core Clock, It stayed at 2115MHz solid during the gaming tests

Cyberpunk (1/2 hour session)

Coolant Temp Under Load 29°C

CPU Temp 43°C

GPU Temp 43°C

GPU Hot Spot 59°C

Memory Junction Temp 53°C

Warzone (1/2 hour session)

Coolant Temp Under Load 29°C

CPU Temp 42°C

GPU Temp 42°C

GPU Hot Spot 60°C

Memory Junction Temp 52°C

Mining 6 hours

+1500 on memory

GPU Avg 37°C

GPU Hot spot 52°C

Memory Junction Temp 73°C

MEM1 43°C

MEM2 43°C

MEM3 46°C

As a test, the home thermostat was adjusted to bring ambient temp to 24°C. The coolant temperature rose to 26°C which means the Delta T for Coolant relative to ambient temperature is 2°C.

Ambient Temp 24°C

Idle Coolant Temp 26°C

Coolant Flow Rate 2 L/min (120 L/h)

+100 Core

Forza Horizon 4 (2 hour session)

Coolant Temp Under Load 31°C

CPU Temp Avg 45°C

GPU Temp Avg 45°C

GPU Hot Spot 61°C

Memory Junction Temp 56°C

Office Temperature and Acoustics

The most important question and why all this work was done; Is my office space still livable after lengthy compute heavy sessions? Answer is YES! The office no longer reaches 28°C like before. It stays to what the thermostat is set to (22°C). The best part is that there is no audible noise from the computer since the fans are set it 20% and all the heavy lifting happens in the other room by the external unit. This allows me to enjoy music in silence and not be bothered by white noise.

Conclusion

This project was a lot of fun from start to end. It was a great learning opportunity working with copper, working with rigid tubing and the parts associated with that ecosystem. It got a little tedious with the details at times but that was to be excepted. It took exactly 3 months from placing orders to getting the PC up and running. This is by far my most involved PC build I have done. The results were definitely worth the effort and this system will go on to serve many years of computing awesomeness. Thank you for taking your time to read through my build log.