Ultimate Home Made PC Desk - by Tankian the Man

For this build, I made a hand-drawn to note some ideas and next a 3D model in "SketchUp" to make sure all the measures and ideas work for the real world.

After having all the planning in 3D done I started to search for the best locations to get all materials I needed, but since isn't my first project I already have some "spots" with good pricing to look at.

Then the building phase starts, the part I like the most (ahaha), and in this particularly project it was a bit challenging because of the size of the desk. The raw build with wood and galvanized metal was pretty straight foward, was I said, I tried always to make sure all the measures are right before cutting anything, by the way I used MDF for the wood.

The most time-consuming part, and "less funny" was the preparation for the primer, it took me a lot of time to sand all the filling putty and make all the edges perfect, but after painting it was more that worth it. I used car related products, like putty, primer, water base coat and clear coat for this project, since my daily job is painting cars.

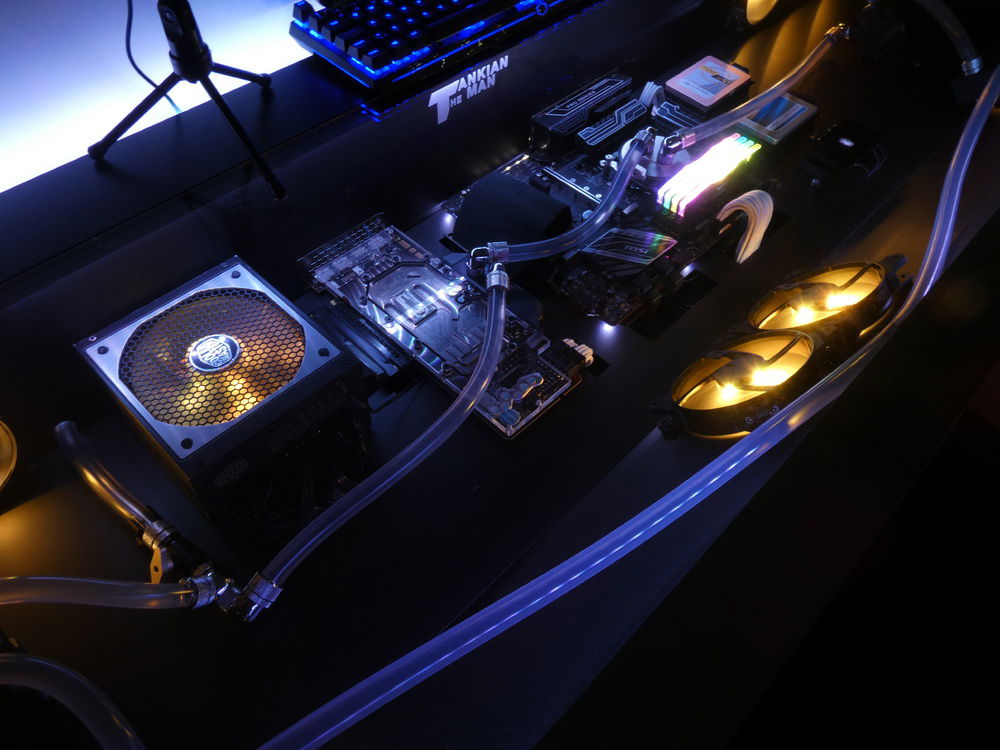

After getting everything done in the workshop, mounting all the components was a little challenging to, since it was the first time I mounted everything together, in the end everything matched was planned!

After having all the planning in 3D done I started to search for the best locations to get all materials I needed, but since isn't my first project I already have some "spots" with good pricing to look at.

Then the building phase starts, the part I like the most (ahaha), and in this particularly project it was a bit challenging because of the size of the desk. The raw build with wood and galvanized metal was pretty straight foward, was I said, I tried always to make sure all the measures are right before cutting anything, by the way I used MDF for the wood.

The most time-consuming part, and "less funny" was the preparation for the primer, it took me a lot of time to sand all the filling putty and make all the edges perfect, but after painting it was more that worth it. I used car related products, like putty, primer, water base coat and clear coat for this project, since my daily job is painting cars.

After getting everything done in the workshop, mounting all the components was a little challenging to, since it was the first time I mounted everything together, in the end everything matched was planned!

Color(s): Black

RGB Lighting? Yes

Theme: Futuristic

Cooling: Custom Liquid Cooling

Size: XL-ATX

Type: General Build

Contests

This build participated in 1 contest.

| Rank | Contest | Date |

|---|---|---|

| #88 | The builds.gg 10K Challenge | ended |

Hardware

CPU

$ 304.35

Motherboard

$ 350.00

Graphics

$ 1,446.00

Storage

$ 99.00

Storage

$ 79.99

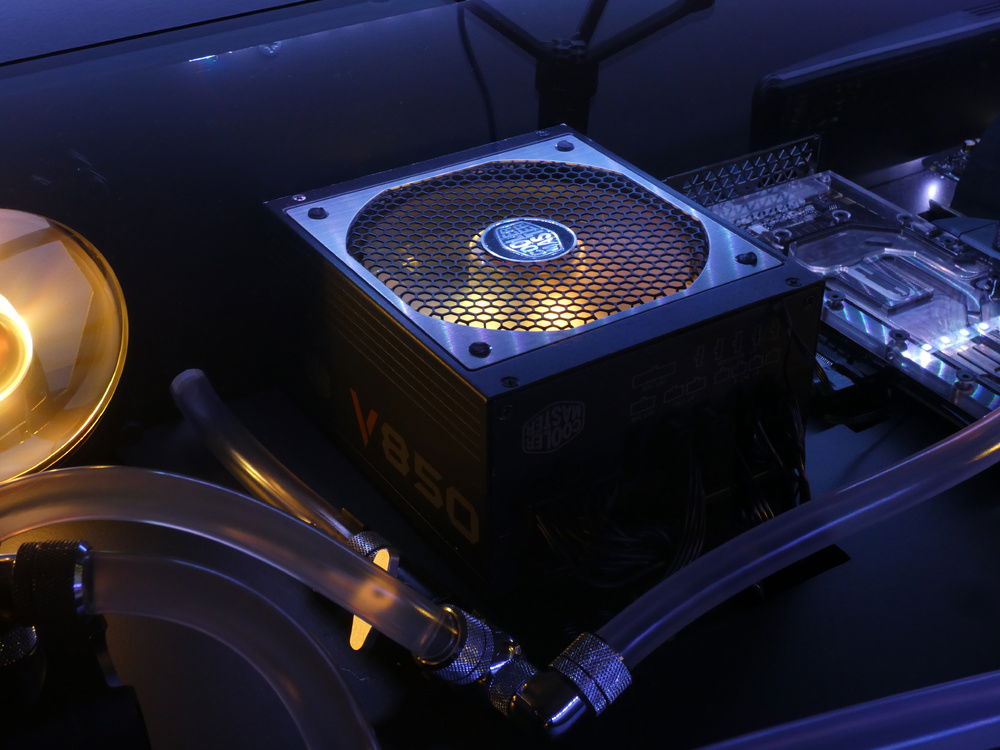

PSU

$ 126.99

Case Fan

$ 24.99

Cooling

Accessories

$ 26.93

Approved by: