Project V

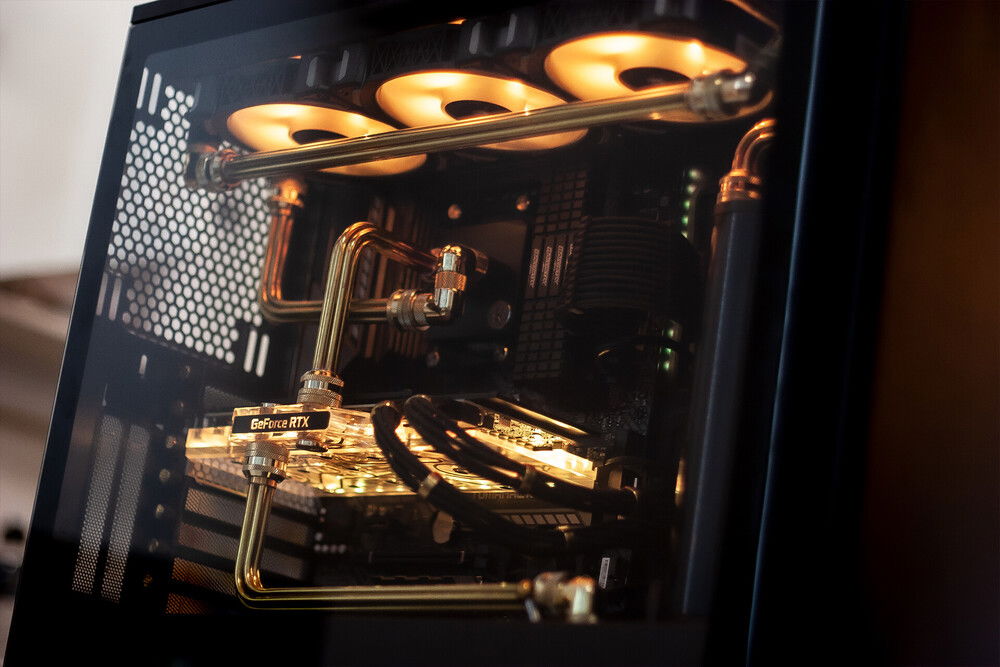

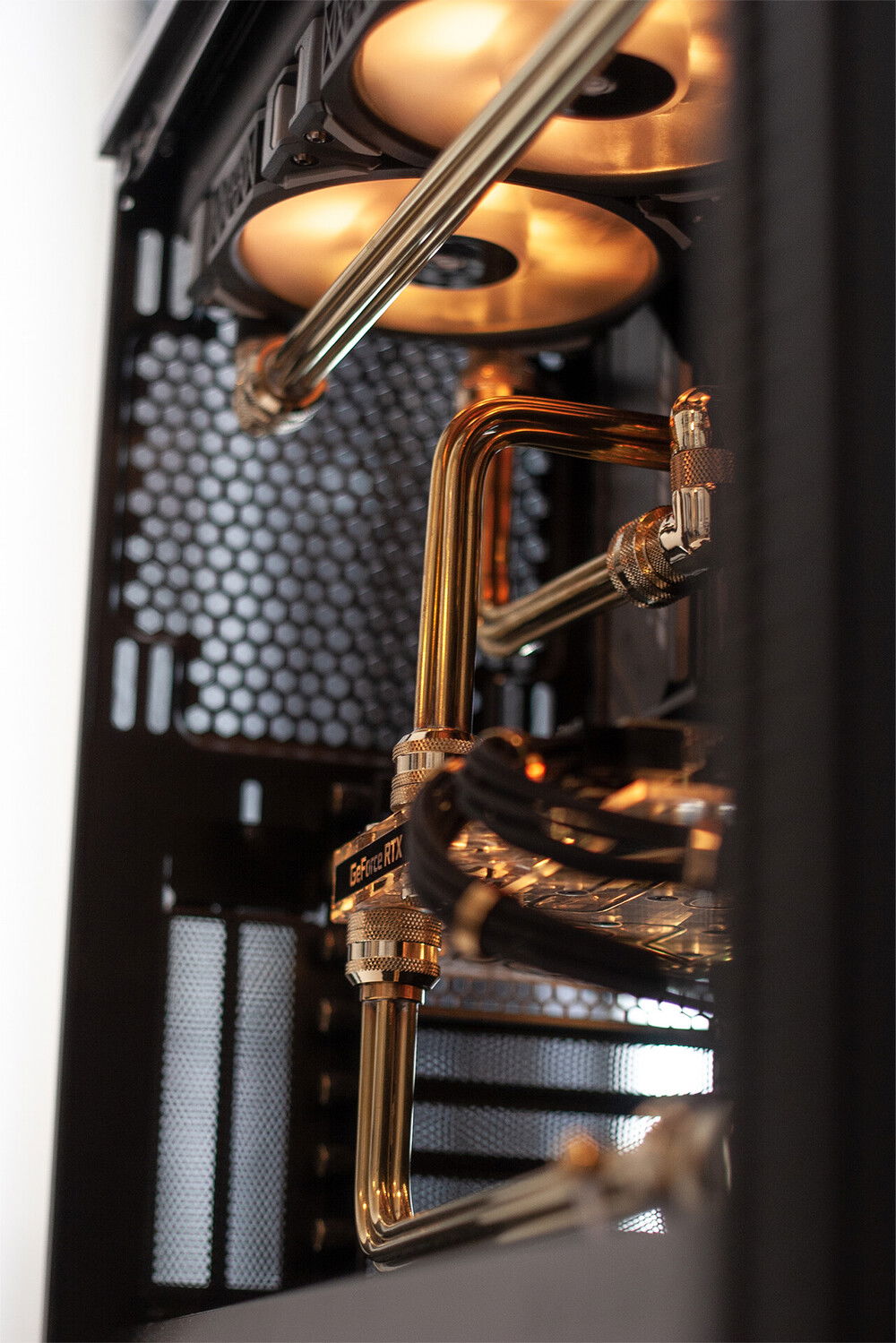

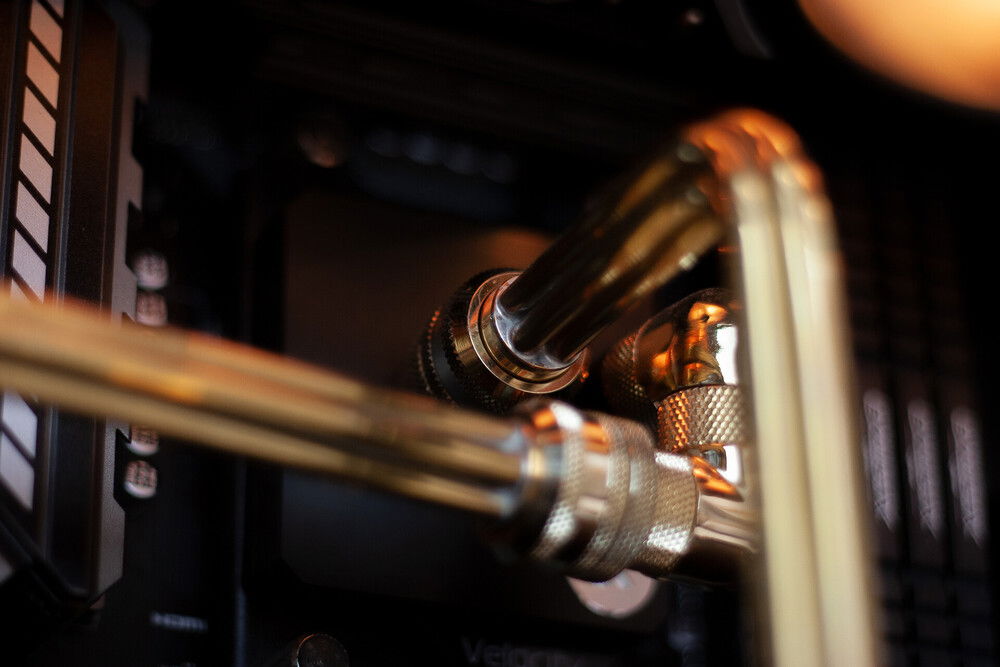

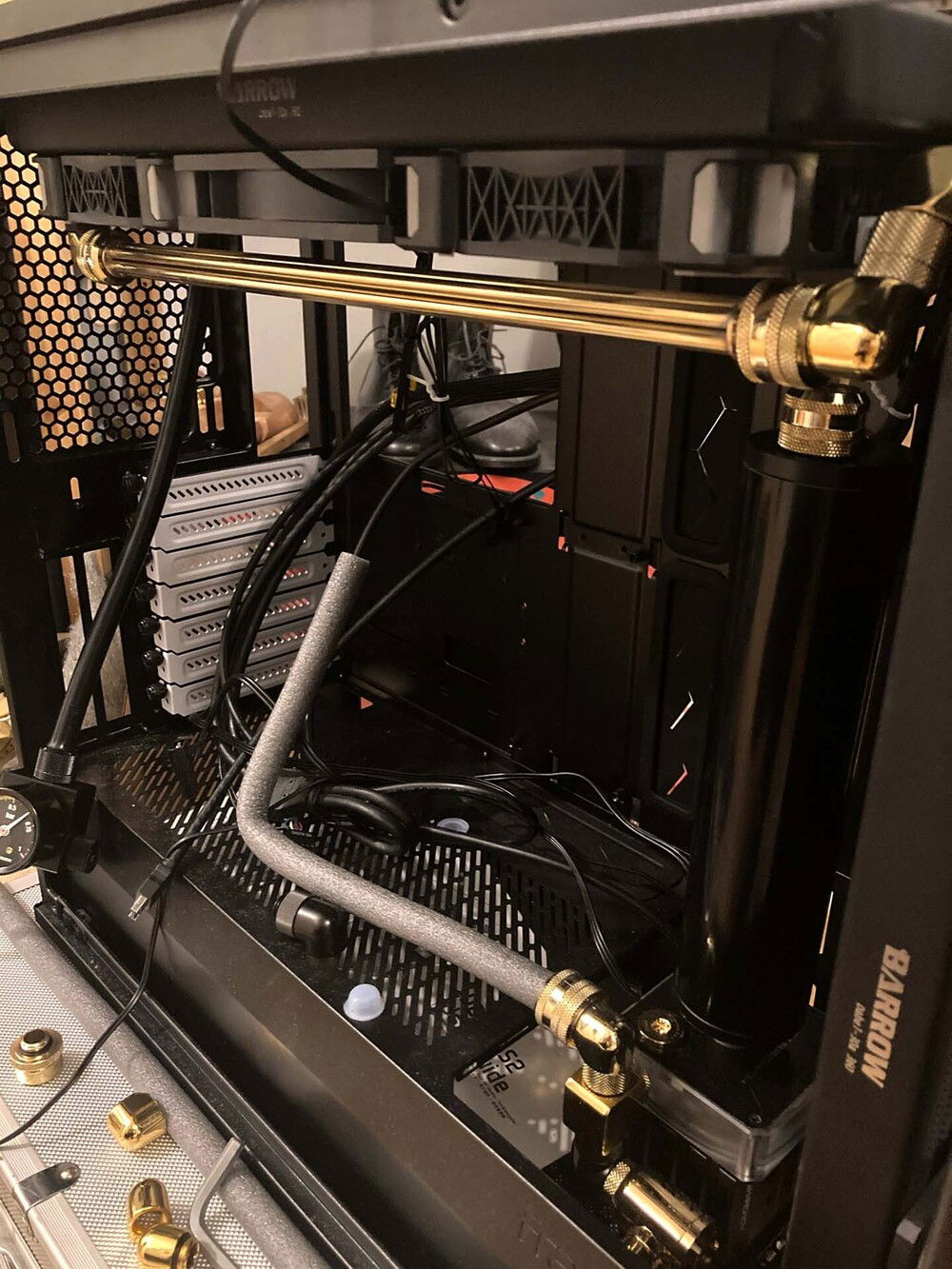

Polished brass build in Fractal Design's case. Each cooling line is made of five ⌀5mm pipes, hence the name V. Pipes are bent with custom made bending tool which had different radiuses for inner, outer and middle pipes.

Other custom stuff:

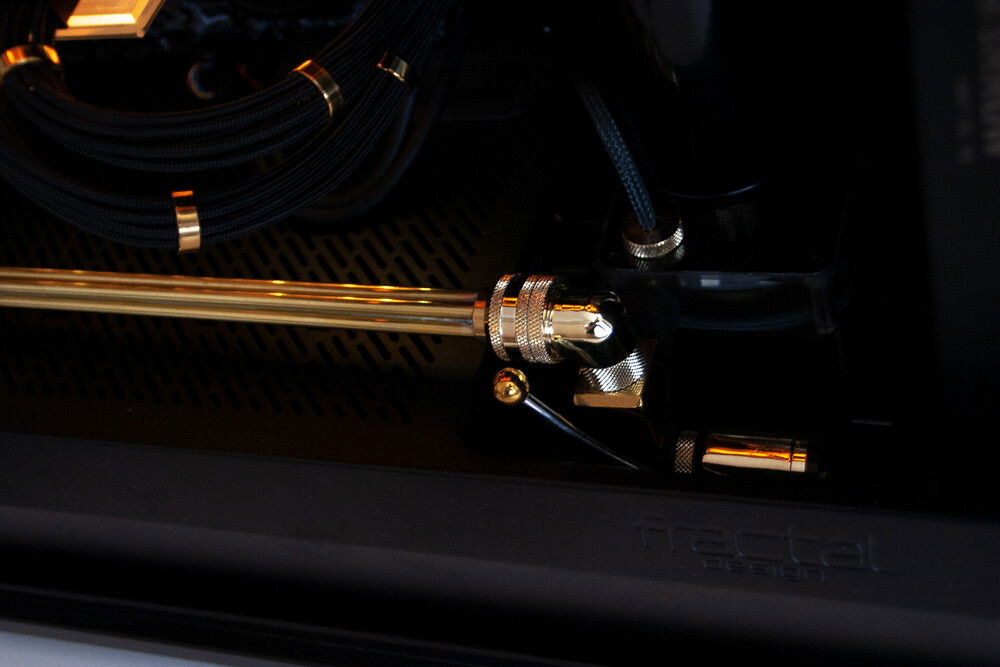

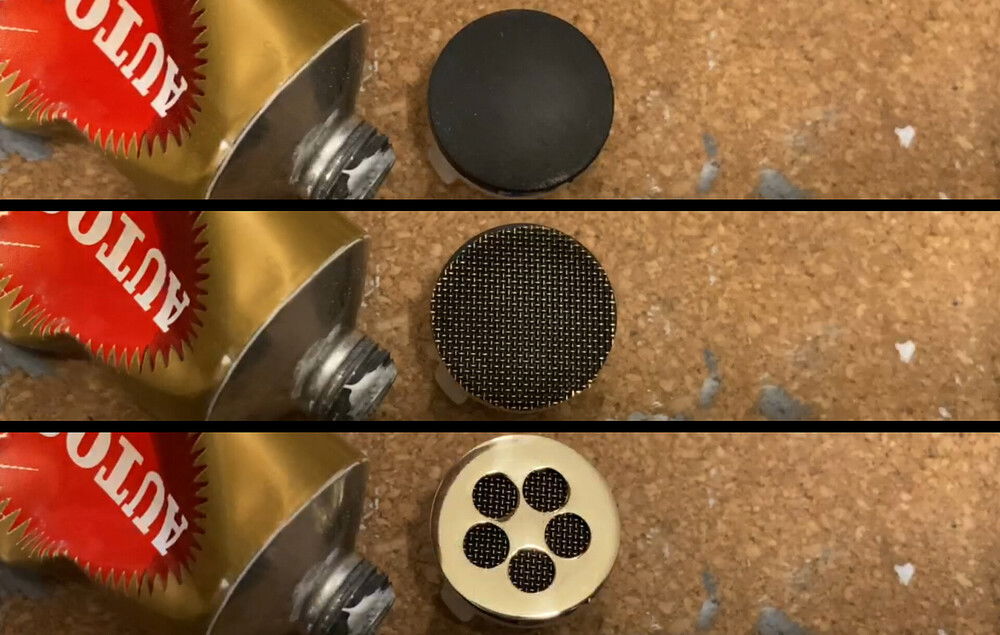

- Brass + mesh power button

- Brass cable 'combs'

- Brass mesh front & top filters

- Custom black reservoir

- Brass screw caps and other smaller things

Other custom stuff:

- Brass + mesh power button

- Brass cable 'combs'

- Brass mesh front & top filters

- Custom black reservoir

- Brass screw caps and other smaller things

Color(s): Black Gold

RGB Lighting? Yes

Theme: none

Cooling: Custom Liquid Cooling

Size: ATX

Type: General Build

Hardware

CPU

$ 248.00

Motherboard

$ 249.99

Memory

$ 241.45

Graphics

Case

$ 124.60

Case Fan

$ 63.00

Cooling

$ 93.50

Cooling

$ 89.99

Approved by: