Most Recent Build

Best Build

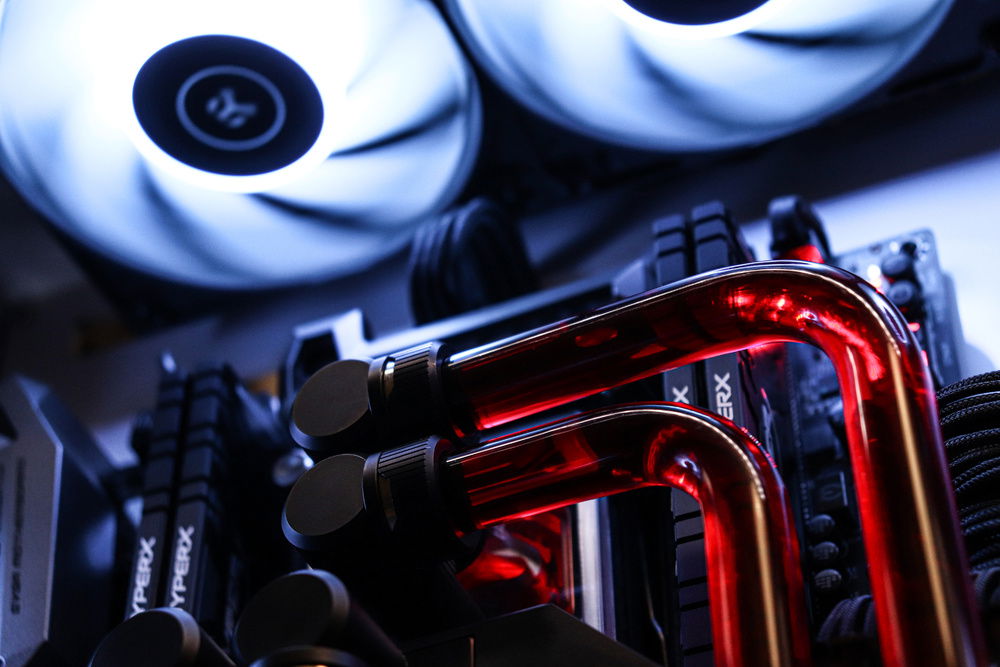

Project Supernova

Project supernova was like a F1 race.

Every bit it’s important. Every small detail matters to the success of the whole build.

Starting from the screws to each precise measurement I took, everything had the same crucial importance.

It required so many skills and techniques, and full time dedication. The whole project took almost 9 months from start to finish.

Everything had to be prefect: every tube has only one way to be connected so standard assembling techniques couldn’t be applied on this build.

I had to re-engineer almost every mounting routine I knew. The radiator to distribution plate tubes for example: I had to slide the radiator and the distribution plate out of the case, install the tubes, slide back in the whole assembly, and secure everything with screws.

Designing Project Supernova my goal was to respect proportions in order to give the project a global sense of harmony and balance between each component.

Project Supernova can’t be categorized as a modding project. It had an engineering vibe since the first day I worked at it. Everything is custom built, the case, the distribution plate and the cable combs on the back.

It was a matter of creating multiple products from scratch, all this excluding testing and prototyping steps from the usual product designing routine. No mistakes were allowed.

Every bit it’s important. Every small detail matters to the success of the whole build.

Starting from the screws to each precise measurement I took, everything had the same crucial importance.

It required so many skills and techniques, and full time dedication. The whole project took almost 9 months from start to finish.

Everything had to be prefect: every tube has only one way to be connected so standard assembling techniques couldn’t be applied on this build.

I had to re-engineer almost every mounting routine I knew. The radiator to distribution plate tubes for example: I had to slide the radiator and the distribution plate out of the case, install the tubes, slide back in the whole assembly, and secure everything with screws.

Designing Project Supernova my goal was to respect proportions in order to give the project a global sense of harmony and balance between each component.

Project Supernova can’t be categorized as a modding project. It had an engineering vibe since the first day I worked at it. Everything is custom built, the case, the distribution plate and the cable combs on the back.

It was a matter of creating multiple products from scratch, all this excluding testing and prototyping steps from the usual product designing routine. No mistakes were allowed.

Color(s): Aluminum Black Red White

RGB Lighting? Yes

Theme: Industrial

Cooling: Custom Liquid Cooling

Size: E-ATX

Type: General Build

Hardware

CPU

$ 139.99

Motherboard

$ 478.86

Memory

$ 244.05

Graphics

$ 1,049.00

Storage

$ 177.00

Seagate - Barracuda Compute (ST1000DM010) (3x)

Form Factor: 3.5 Inch

Interface: SATA 6 Gb/s

Capacity: 1 TB

PSU

$ 120.44

Cooling

$ 100.00

Cooling

$ 29.95

Cooling

$ 103.99

Cooling

Cooling

$ 212.41

Cooling

Cooling

$ 226.21