LUMI

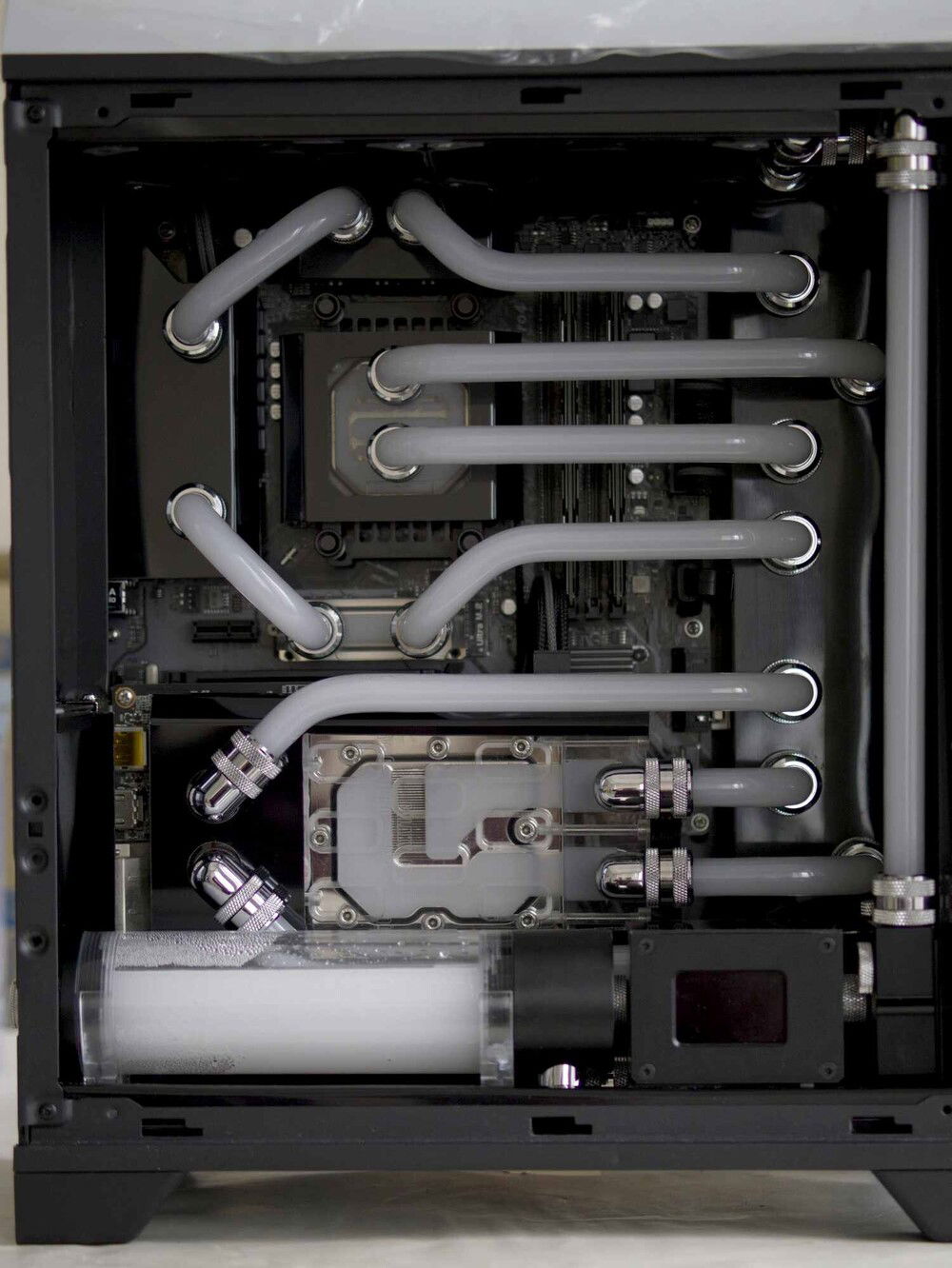

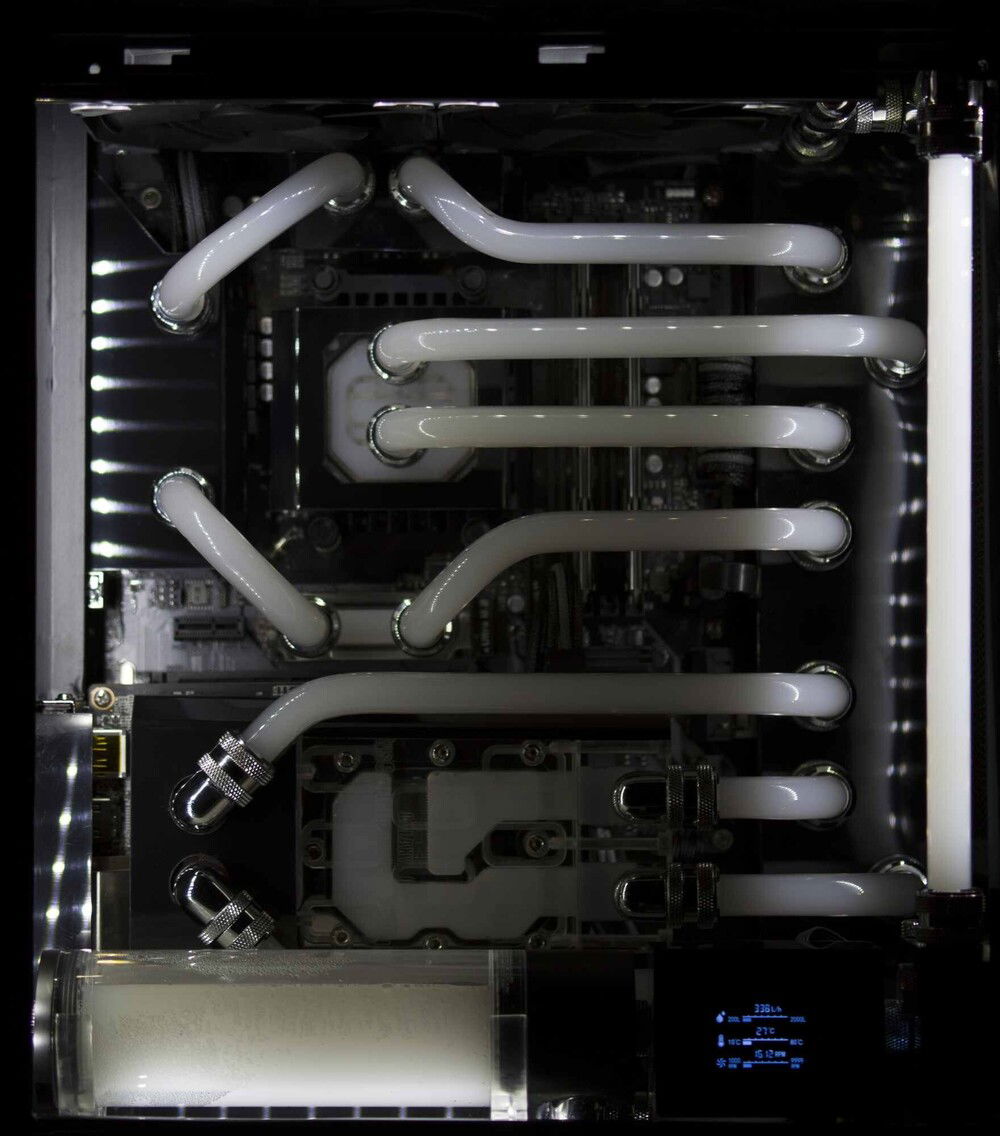

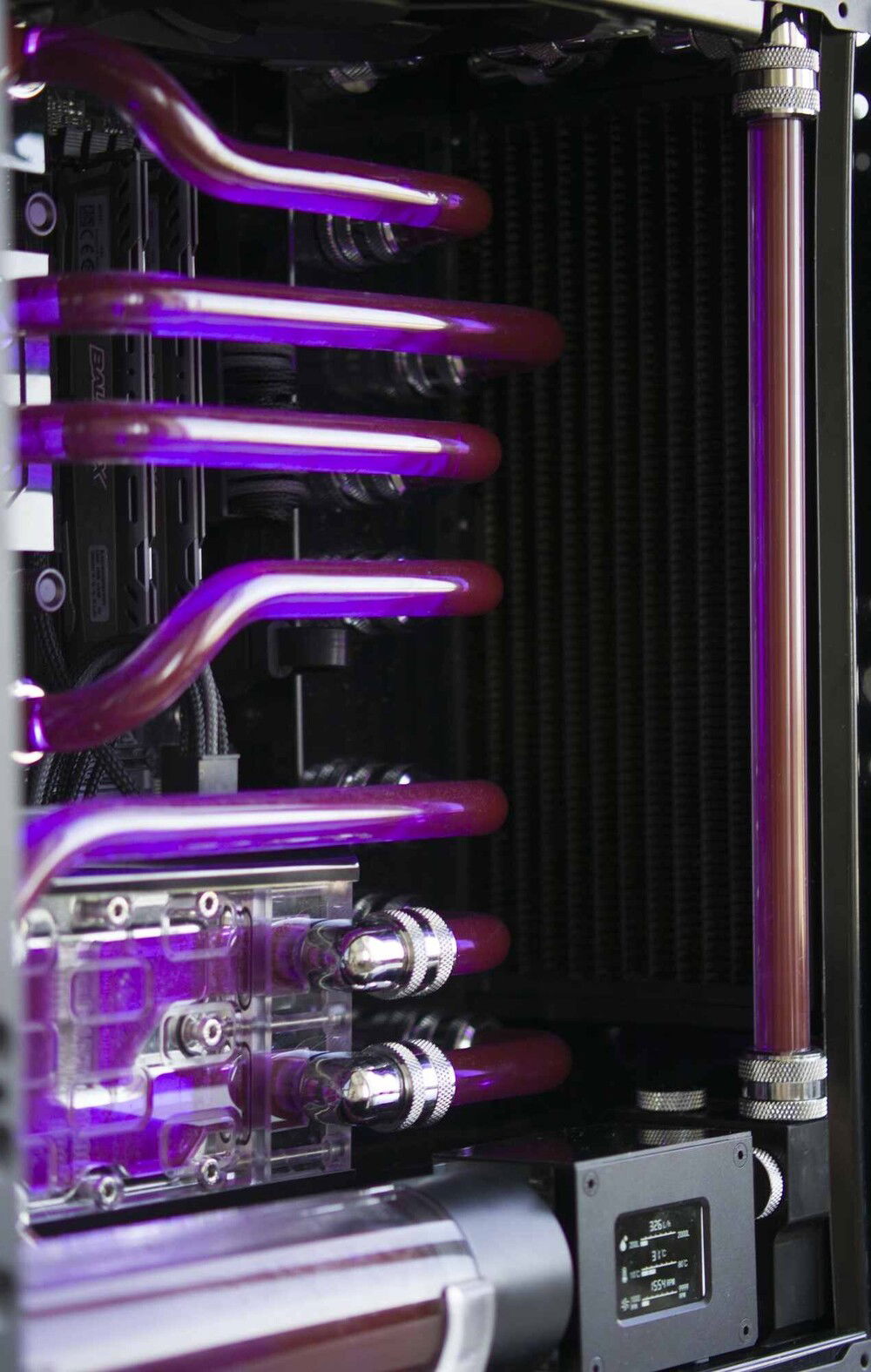

This was my first attempt at modding and water cooling. This case was made in 2019. I used only simple hand tools to build it. No special goals, just tried to make it as clean as possible. But in the process as usual I got carried away, new ideas came, and tried to realize them all. The interior space had to be completely redesigned, remove the compartment under the PSU, replace the PSU itself with a server 1U, added a second 240mm radiator at the top of the case, as well as added a design for vertical installation of the video card.

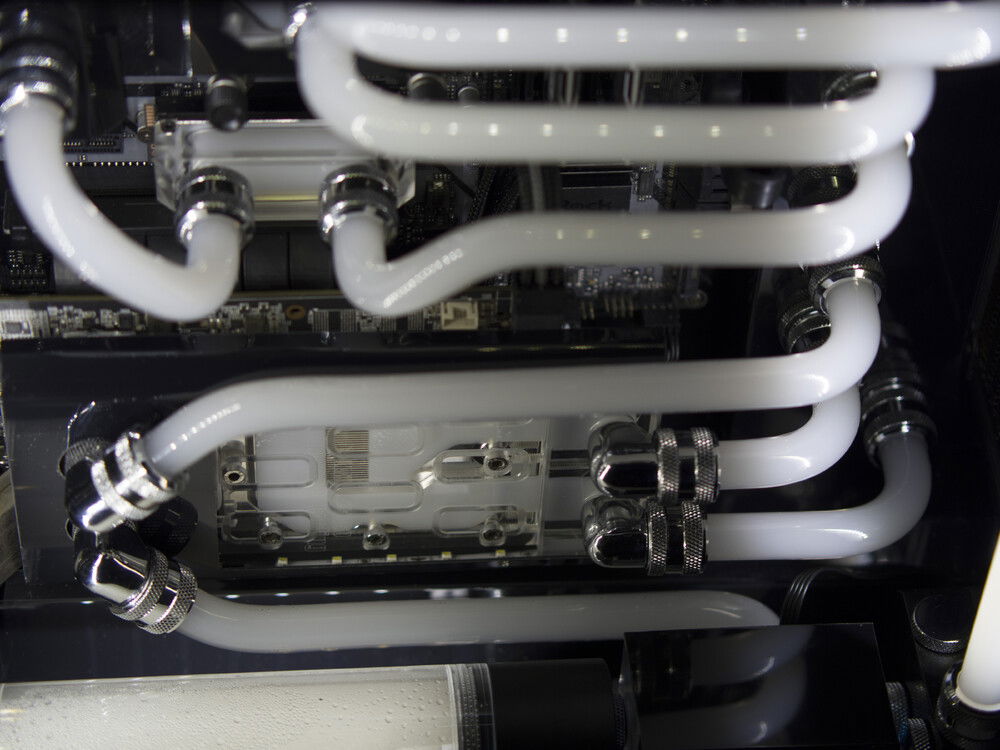

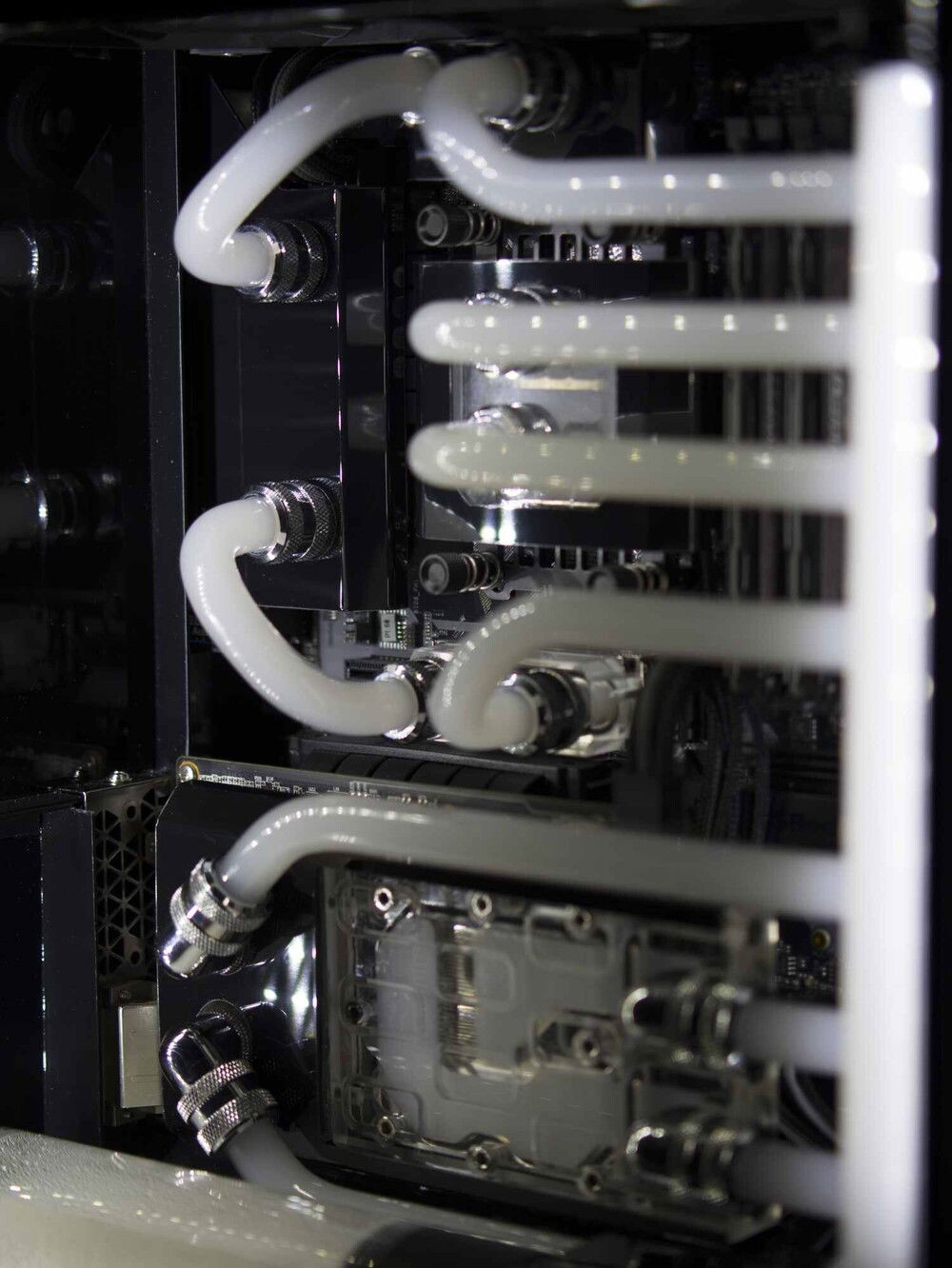

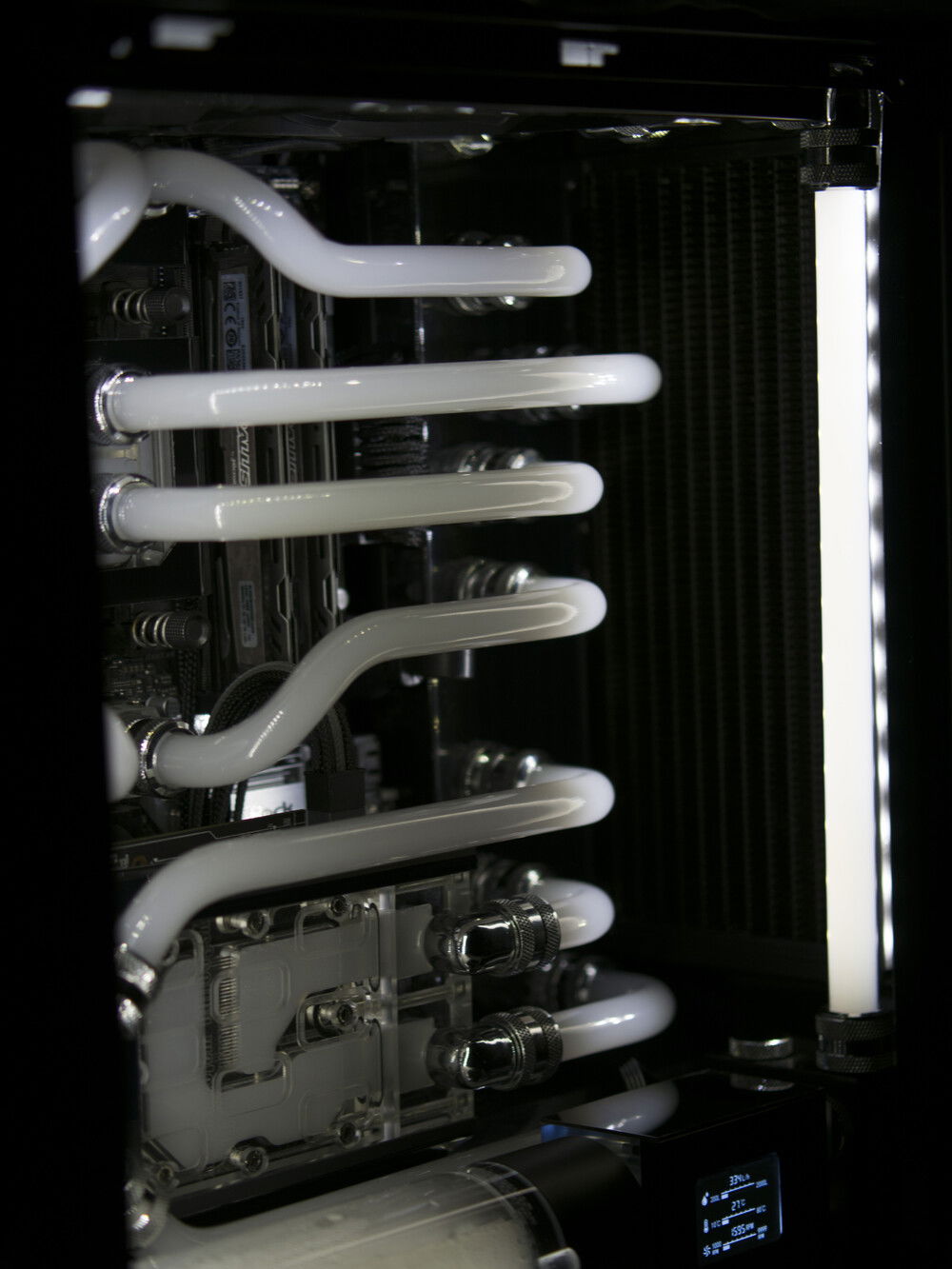

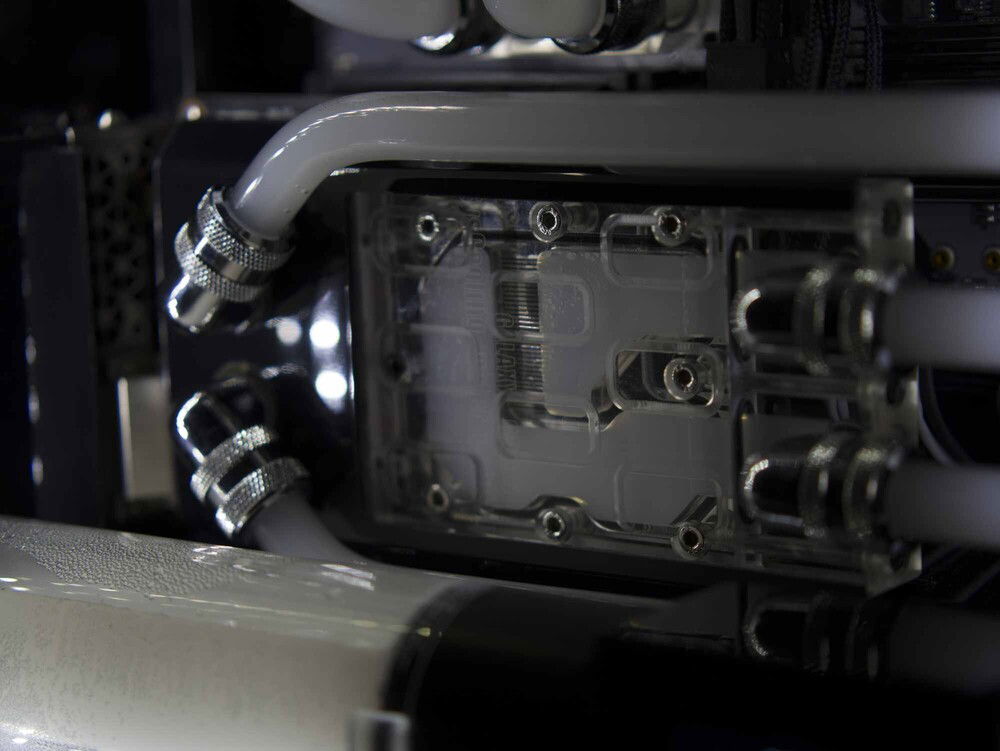

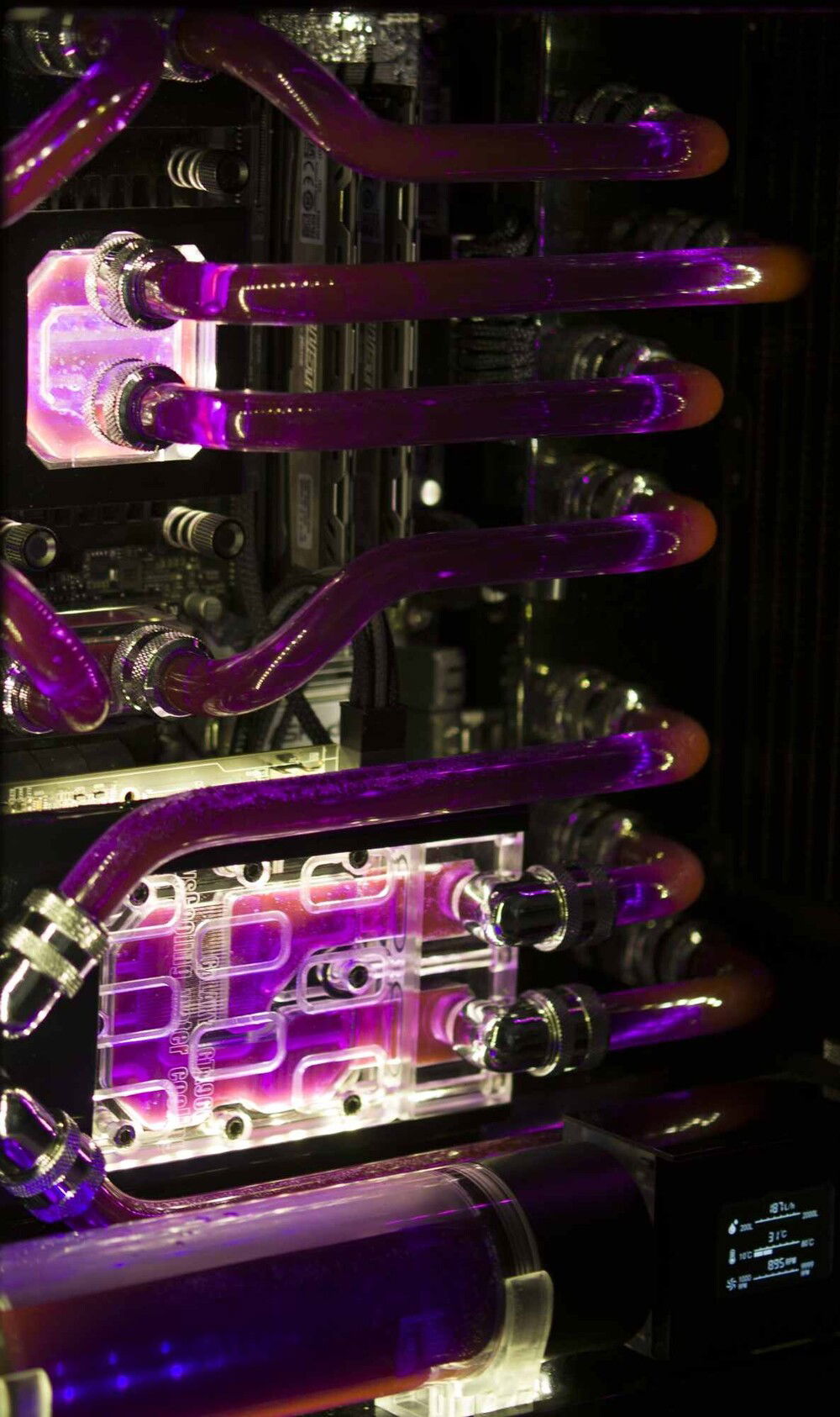

With the video card it turned out to be a rather unconventional solution. There was no fullcover waterblock for my video card. I thought I would just change it for another one, but then I saw a semifull waterblock from another card on sale. After studying the design of PCB I realized that if I turn this waterblock to 90 degrees it can be used. And so it turned out to be, it fit almost without any modifications. But the VRM remained without cooling, so I added a standard 6cm long waterblock. To combine these two different looking waterblocks into one design I added a thin plastic cover.

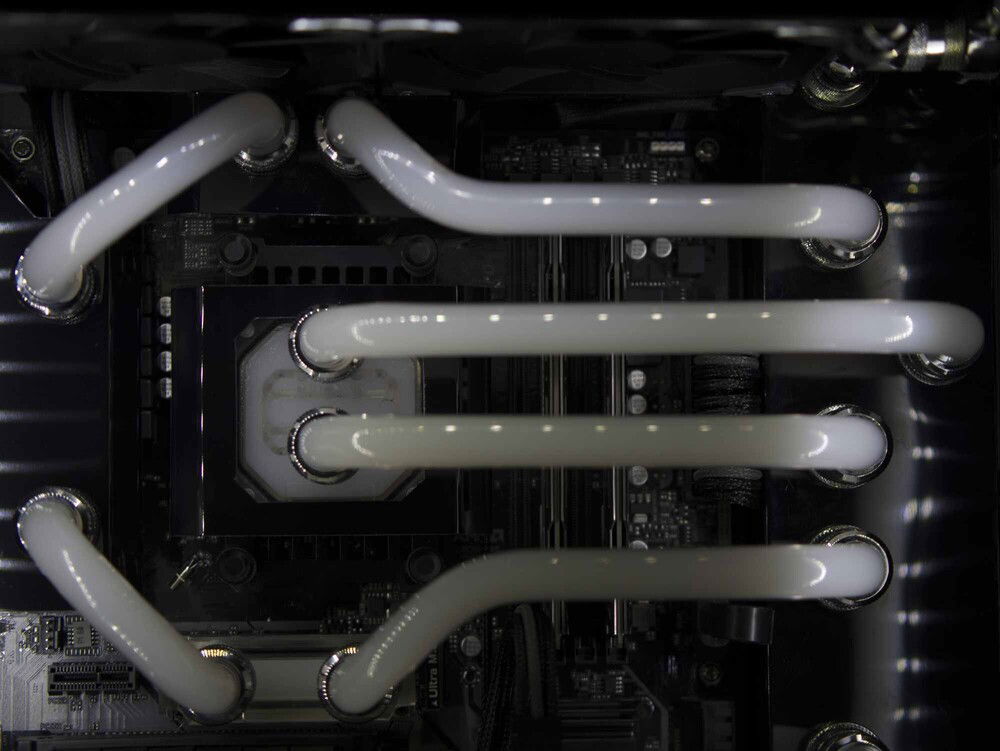

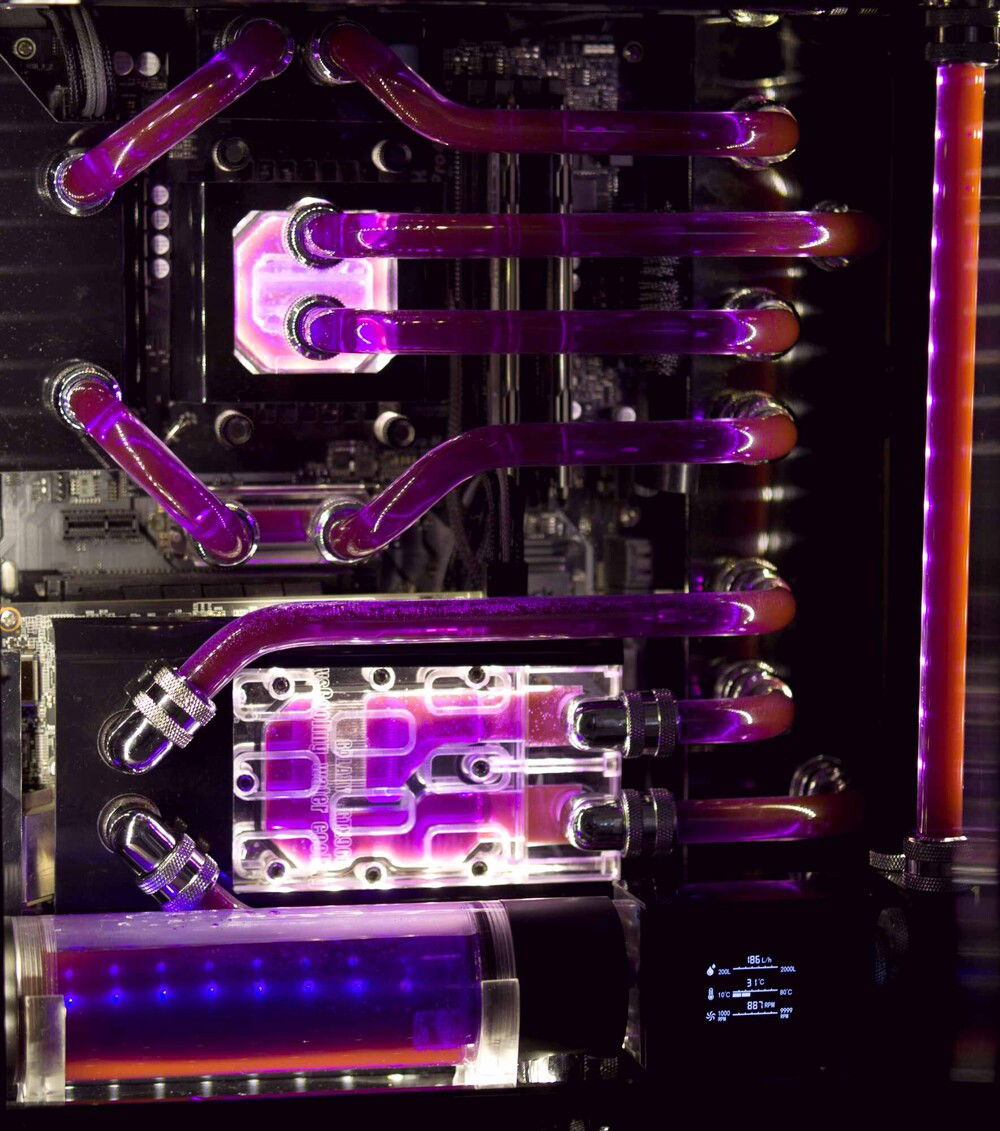

It worked out about the same with the motherboard. I chose a board with the most symmetrical location of the VRM relative to the socket. I added two standard waterblocks, 8cm and 6cm, to the VRM. And there was also a waterblock on the M.2 to maintain the symmetry of the layout. I also covered all waterblocks with thin plastic to keep everything in the same style.

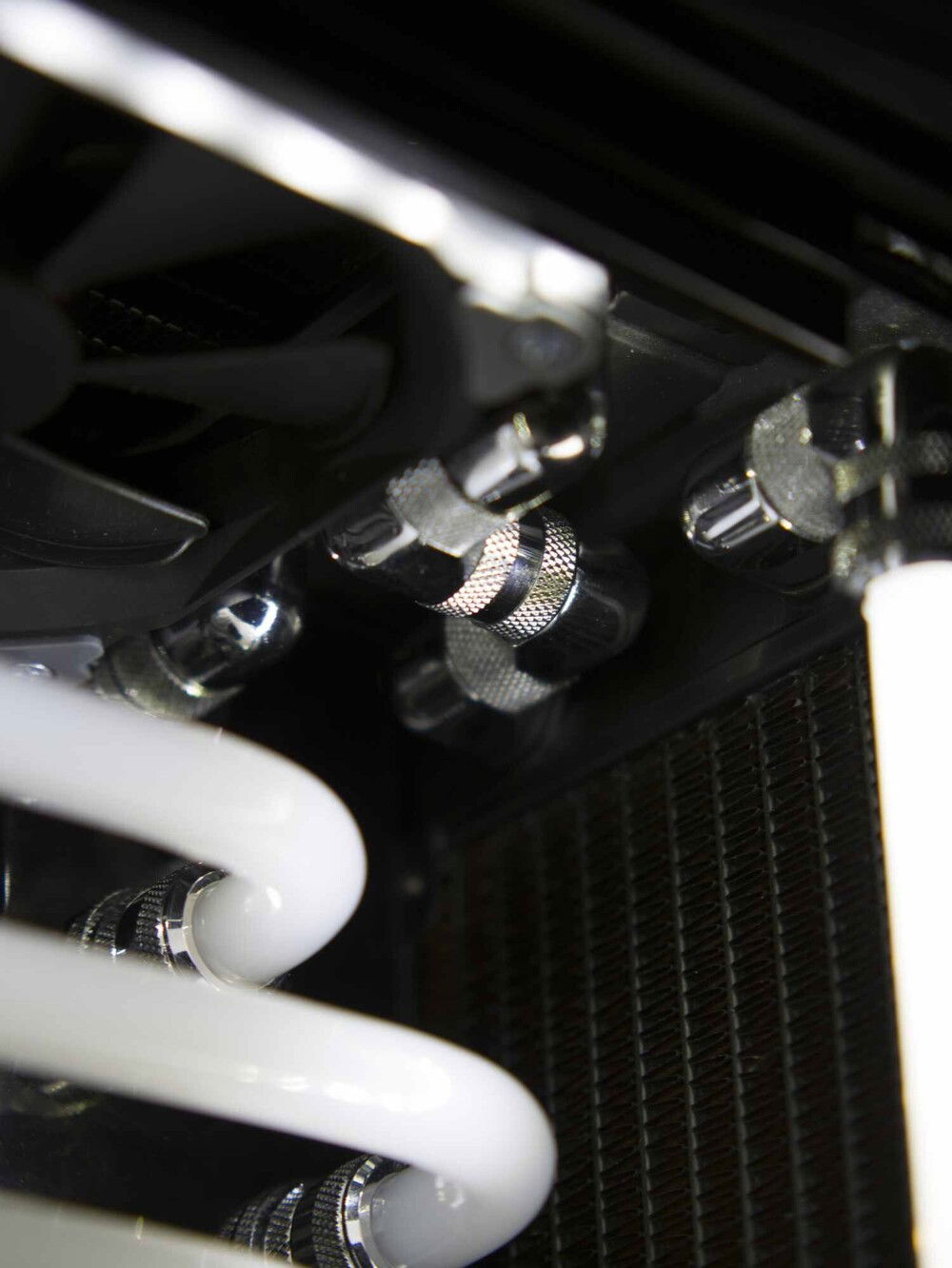

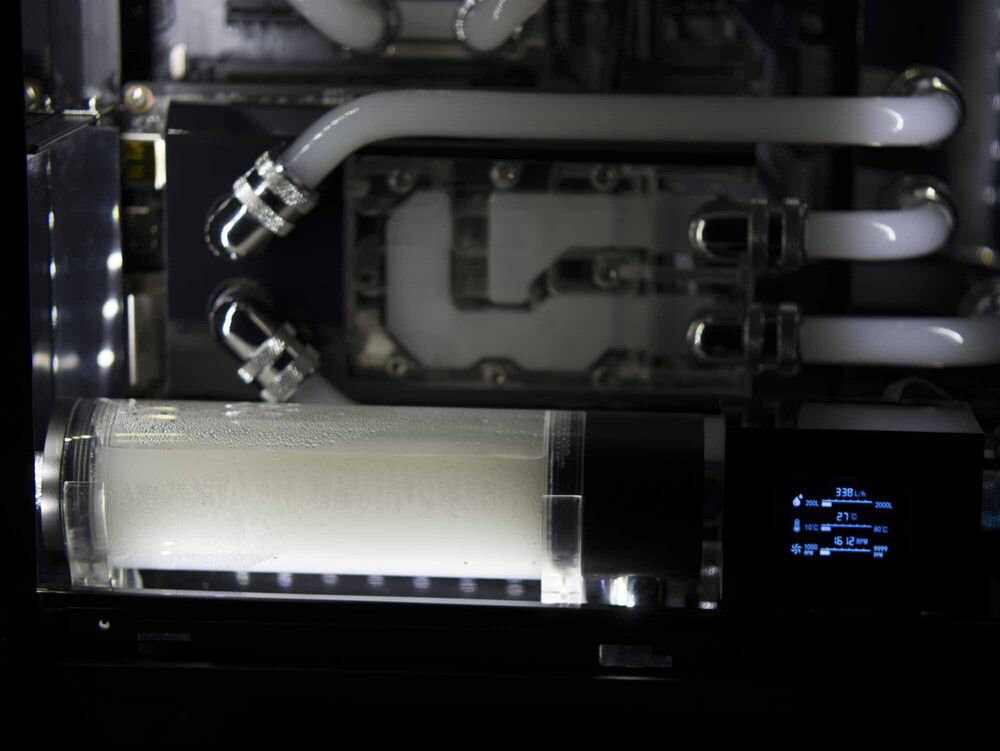

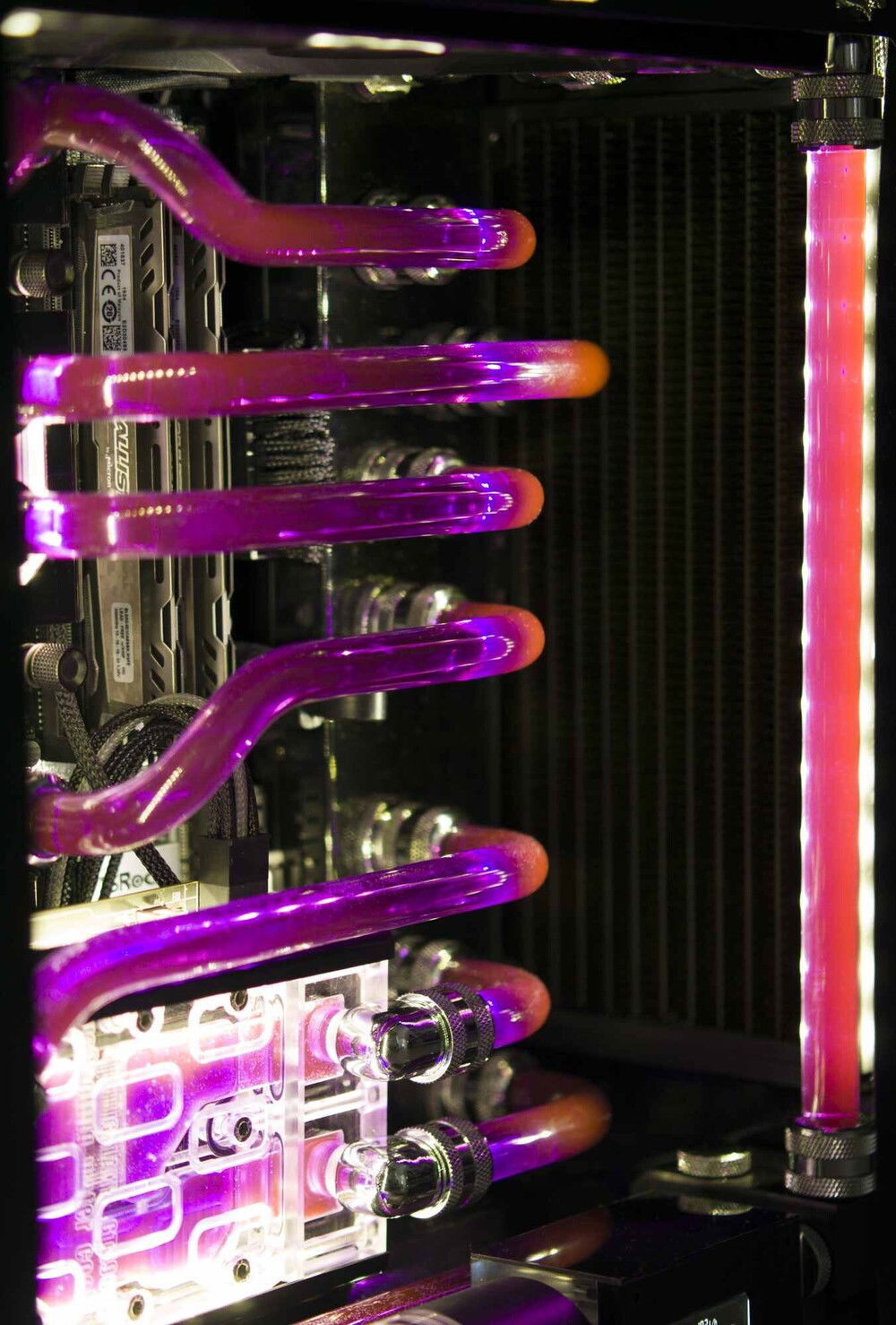

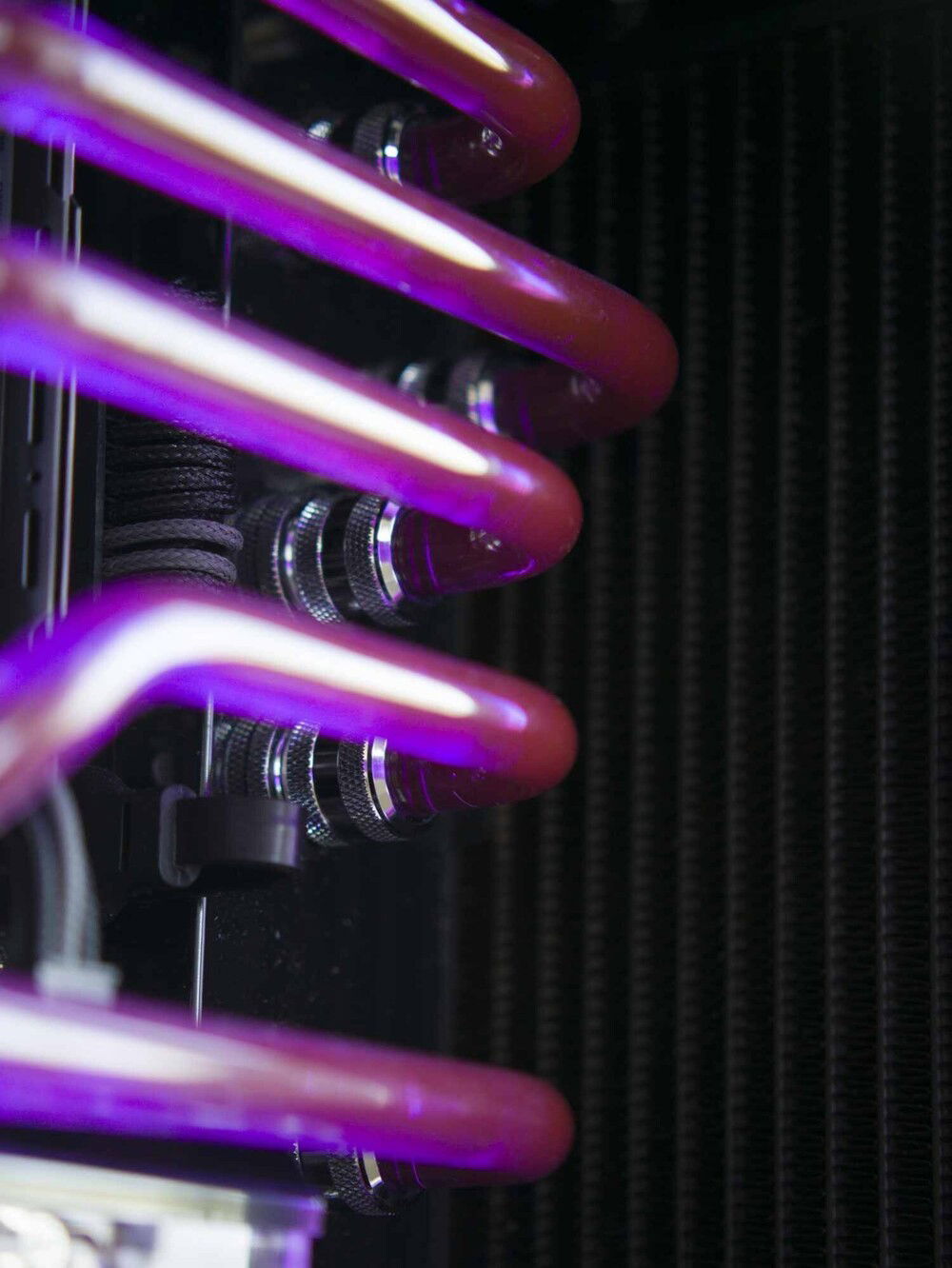

Really wanted to apply a distro plate, but I had no way to fabricate one. So I used pass-through fittings and regular 90 degree fittings on the back side. Because of the height of these 90 degree fittings, the radiators no longer fit in their places. So I made a custom mount for them. It turned out pretty accurate and I was able to connect both radiators with just the fittings.

As a result, cooling turned out to be quite complicated: оverall 6 waterblocks, CPU and m.2 by Barrow, semifull for video galaxy 960, 2 universal VRM blocks for mobo and one for VRM video, 2x240mm radiators, pump Syscooling P60, flow speed meter from Freezemod, model LSJ-ZN, PETG tubes 10/14.

Despite the large amount of work, the hardest part of this case was the planning. The planning itself proved to be difficult, with the closer to the end of the project, the more complex it became. A lot of things had to be coordinated so that nothing got in the way. By simplifying in one place, it was easy to overcomplicate in several other places. That's why this case turned out to be a set of very many compromises. Of course, there are many things I would like to do differently, some things I would do differently now, but without experience it is very difficult to do something well thought out from the start.

With the video card it turned out to be a rather unconventional solution. There was no fullcover waterblock for my video card. I thought I would just change it for another one, but then I saw a semifull waterblock from another card on sale. After studying the design of PCB I realized that if I turn this waterblock to 90 degrees it can be used. And so it turned out to be, it fit almost without any modifications. But the VRM remained without cooling, so I added a standard 6cm long waterblock. To combine these two different looking waterblocks into one design I added a thin plastic cover.

It worked out about the same with the motherboard. I chose a board with the most symmetrical location of the VRM relative to the socket. I added two standard waterblocks, 8cm and 6cm, to the VRM. And there was also a waterblock on the M.2 to maintain the symmetry of the layout. I also covered all waterblocks with thin plastic to keep everything in the same style.

Really wanted to apply a distro plate, but I had no way to fabricate one. So I used pass-through fittings and regular 90 degree fittings on the back side. Because of the height of these 90 degree fittings, the radiators no longer fit in their places. So I made a custom mount for them. It turned out pretty accurate and I was able to connect both radiators with just the fittings.

As a result, cooling turned out to be quite complicated: оverall 6 waterblocks, CPU and m.2 by Barrow, semifull for video galaxy 960, 2 universal VRM blocks for mobo and one for VRM video, 2x240mm radiators, pump Syscooling P60, flow speed meter from Freezemod, model LSJ-ZN, PETG tubes 10/14.

Despite the large amount of work, the hardest part of this case was the planning. The planning itself proved to be difficult, with the closer to the end of the project, the more complex it became. A lot of things had to be coordinated so that nothing got in the way. By simplifying in one place, it was easy to overcomplicate in several other places. That's why this case turned out to be a set of very many compromises. Of course, there are many things I would like to do differently, some things I would do differently now, but without experience it is very difficult to do something well thought out from the start.

Color(s): Black

RGB Lighting? No

Theme: none

Cooling: Custom Liquid Cooling

Size: Micro-ATX

Type: General Build

Hardware

CPU

$ 99.00

Motherboard

Memory

Storage

$ 29.99

PSU

$ 175.84

Case

Approved by: