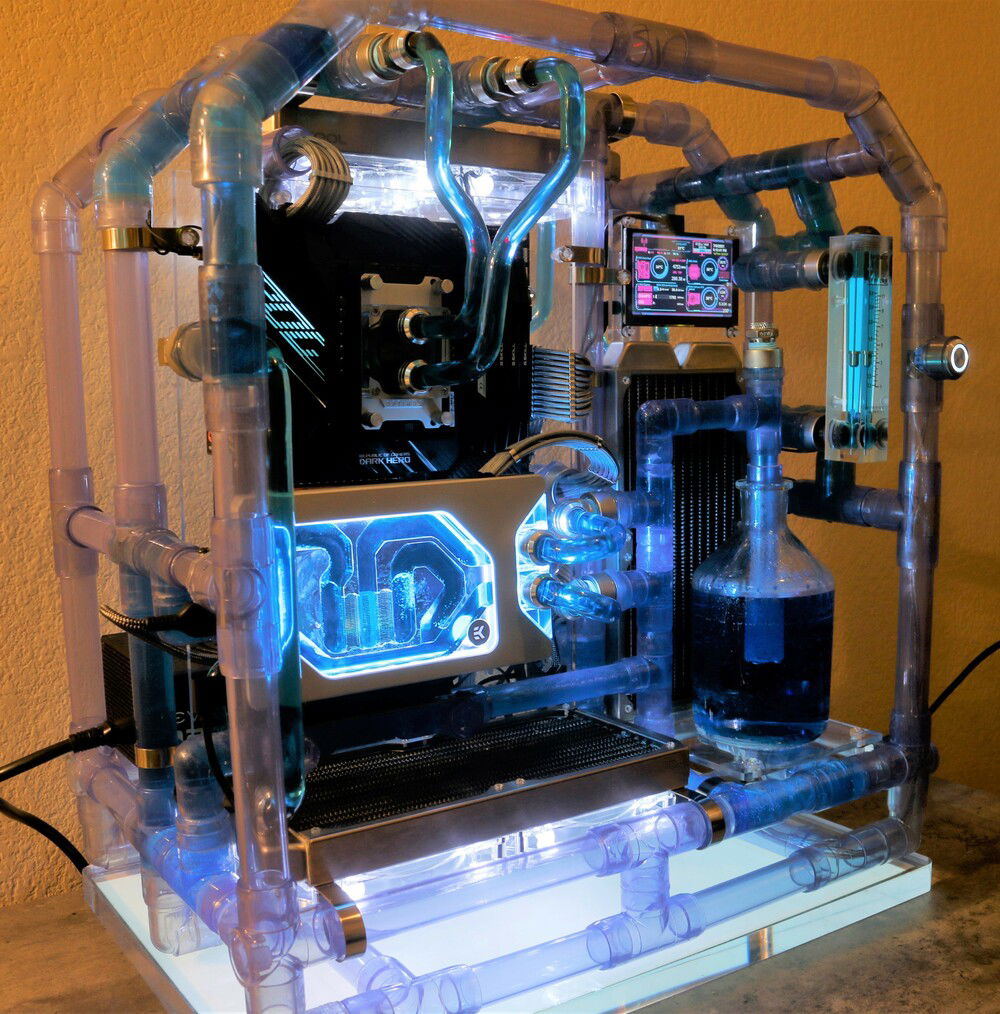

The Iceman

Case: Full custom, clear PVC pipes, acrylic backplate, custom GPU mount, etc…

CPU: 5900x

GPU: NVidia 3090 FE

Memory: 4x16GB G.SKILL Ripjaws DDR 3600

Motherboard: ASUS Dark Hero x570

GPU Waterblock: EK-Quantum Vector FE RTX 3090 - Special Edition Silver

CPU Waterblock: Optimus Foundation Pro-XE Nickel

Cables: CableMod - ModFlex - Silver (24 Pin, 4+8 Pin EPS, 12 Pin Micro PCI-E, SATA, Molex)

PSU: EVGA SuperNOVA P2 1200

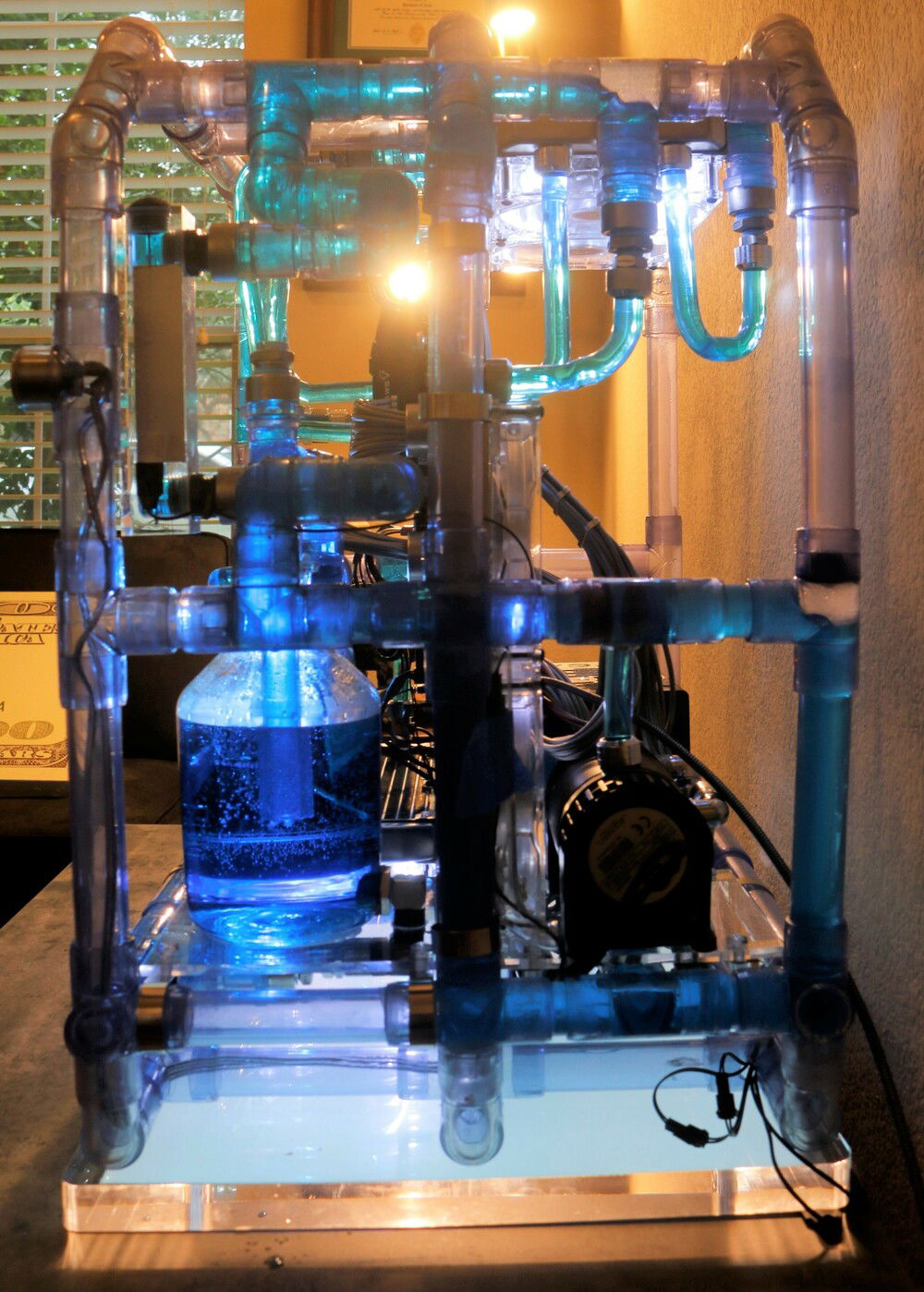

Pump: EKWB Dual D5

Fittings: Alphacool Eiszapfen 16mm, Stainless 1/4 NPT Fittings

Case Tubing: ¾” Clear PVC (UV)

Fitting Tubing: 16mm Monsoon PETG

Radiators: 3 x Alphacool NexXxoS ST30 280mm- Stainless

Fans: 6 x Anidees 140mm White LED Transparent Fan

Flow Meter: Mechanical ½”

Temperature Sensor: koolance Coolant Temperature Sensor - Inline (10k Ohm)

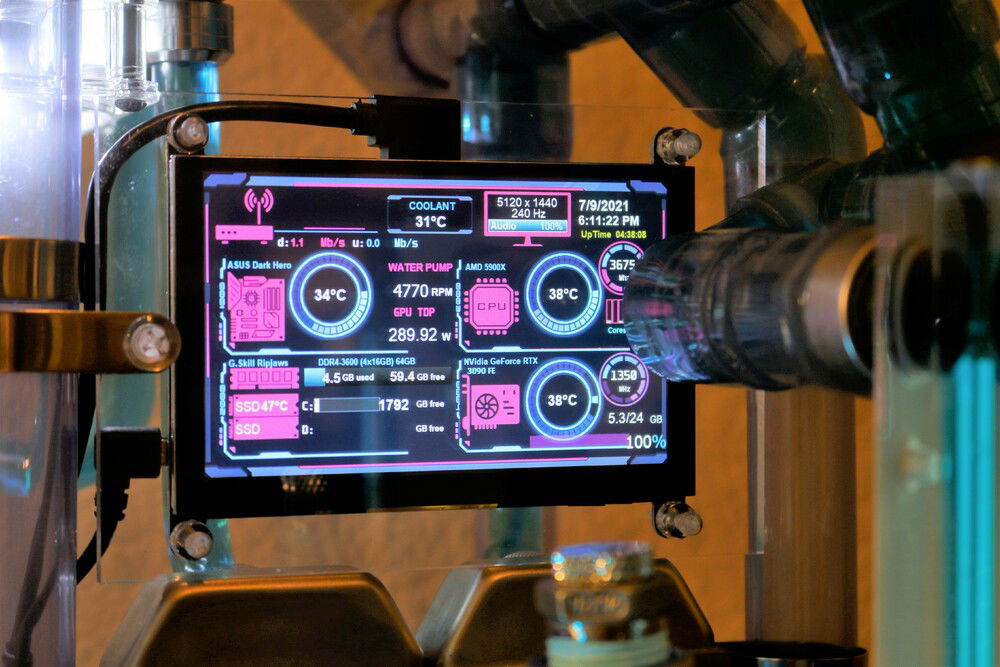

Sensor Panel: 800x480 (5 Inch) Monitor - HDMI (AIDA64)

Platform: Custom cut 24mm thick acrylic with a custom EL panel for underlighting

The obsession about watercooling has gotten real. It started escalating into copper with the Growler (https://builds.gg/builds/the-growler-29530) and that left me wanting to make the next build out of clear PVC. Why? Because you can see the flow of the coolant through the loop, and when your case is the distribution block, that has to be interesting.

The biggest challenge of this build is PVC.

1) Clear PVC is expensive and hard to get due to manufacturing shortages of all PVC due to the pandemic. Just try and buy generic white PVC fittings at Home Depot. They are cleared out. Clear PVC is only manufactured by a few companies and at times I was clearing out all of the stock of fittings.

2) PVC is "glue once stuck forever." That is down right nerve racking when you are cementing as many joints as this build requires. One mistake and I would have to throw away a huge amount of PVC and fittings. With challenge #1 above (availability), there are some big commitment moments in using PVC cement.

I genuinely had fun using pipes for interesting uses and cable routing in this build.

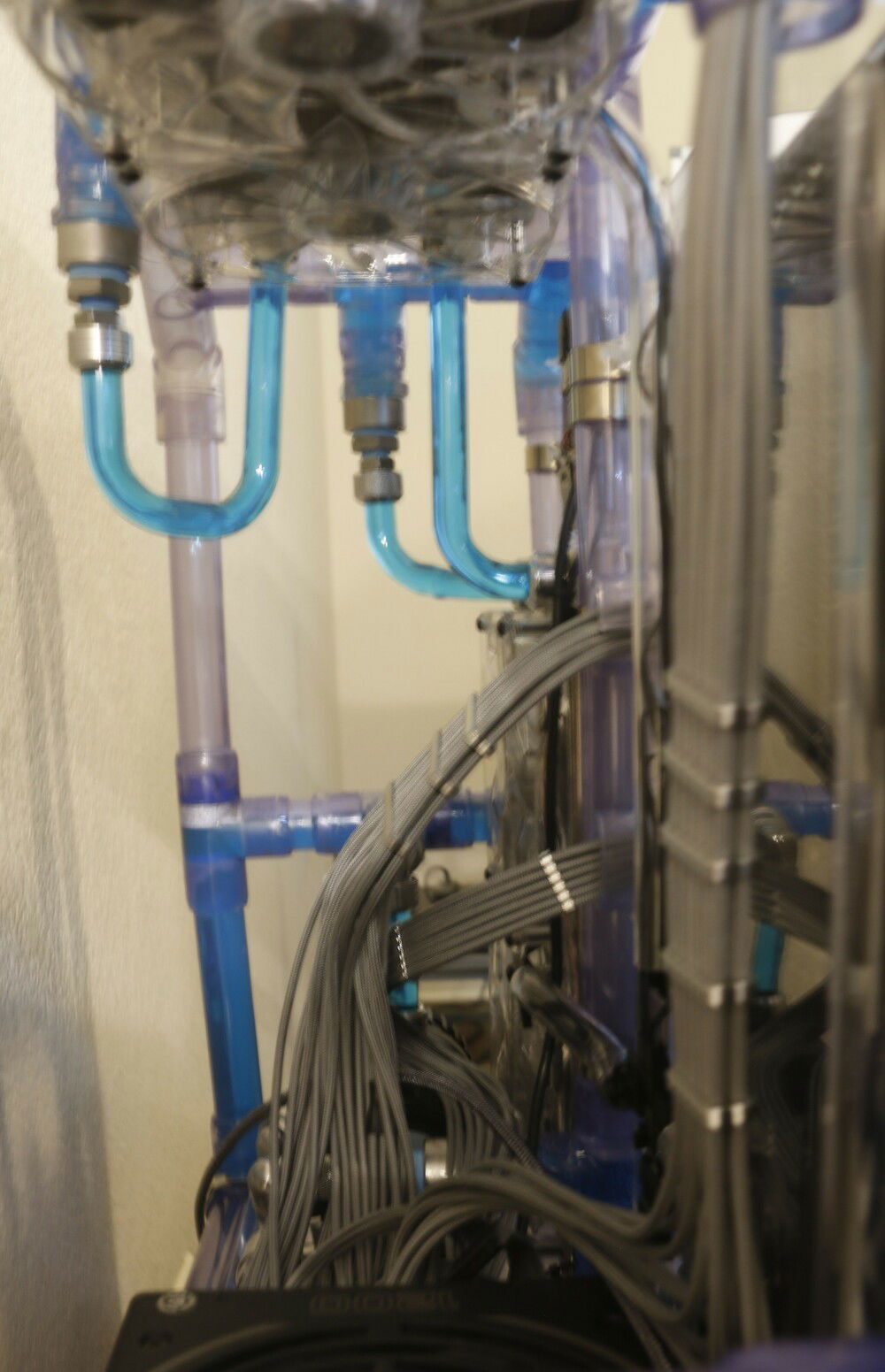

Check out the routing of the CableMod ATX 24-pin and the PCI-E cables. I was able to mount fittings through the acrylic backplate to have the cables run through those fittings to the front side of the case. The ModFlex cables work well for flexible routing like this as I had to squeeze the cables and cable combs though some small openings in the fittings.

In the back of the case, I used 16mm PETG to cleanly route the fan cables and some of the ancillary cables for the water pumps, temperature sensor, etc.

This was the first time I have used a sensor panel and AIDA64. I was impressed with how much information is out there about creating displays, availability of templates, etc... Ended up showing a lot of information in a 800x480 display.

The case is sitting on a custom cut 24mm (1") thick piece of acrylic with a custom EL panel underneath for illumination.

CPU: 5900x

GPU: NVidia 3090 FE

Memory: 4x16GB G.SKILL Ripjaws DDR 3600

Motherboard: ASUS Dark Hero x570

GPU Waterblock: EK-Quantum Vector FE RTX 3090 - Special Edition Silver

CPU Waterblock: Optimus Foundation Pro-XE Nickel

Cables: CableMod - ModFlex - Silver (24 Pin, 4+8 Pin EPS, 12 Pin Micro PCI-E, SATA, Molex)

PSU: EVGA SuperNOVA P2 1200

Pump: EKWB Dual D5

Fittings: Alphacool Eiszapfen 16mm, Stainless 1/4 NPT Fittings

Case Tubing: ¾” Clear PVC (UV)

Fitting Tubing: 16mm Monsoon PETG

Radiators: 3 x Alphacool NexXxoS ST30 280mm- Stainless

Fans: 6 x Anidees 140mm White LED Transparent Fan

Flow Meter: Mechanical ½”

Temperature Sensor: koolance Coolant Temperature Sensor - Inline (10k Ohm)

Sensor Panel: 800x480 (5 Inch) Monitor - HDMI (AIDA64)

Platform: Custom cut 24mm thick acrylic with a custom EL panel for underlighting

The obsession about watercooling has gotten real. It started escalating into copper with the Growler (https://builds.gg/builds/the-growler-29530) and that left me wanting to make the next build out of clear PVC. Why? Because you can see the flow of the coolant through the loop, and when your case is the distribution block, that has to be interesting.

The biggest challenge of this build is PVC.

1) Clear PVC is expensive and hard to get due to manufacturing shortages of all PVC due to the pandemic. Just try and buy generic white PVC fittings at Home Depot. They are cleared out. Clear PVC is only manufactured by a few companies and at times I was clearing out all of the stock of fittings.

2) PVC is "glue once stuck forever." That is down right nerve racking when you are cementing as many joints as this build requires. One mistake and I would have to throw away a huge amount of PVC and fittings. With challenge #1 above (availability), there are some big commitment moments in using PVC cement.

I genuinely had fun using pipes for interesting uses and cable routing in this build.

Check out the routing of the CableMod ATX 24-pin and the PCI-E cables. I was able to mount fittings through the acrylic backplate to have the cables run through those fittings to the front side of the case. The ModFlex cables work well for flexible routing like this as I had to squeeze the cables and cable combs though some small openings in the fittings.

In the back of the case, I used 16mm PETG to cleanly route the fan cables and some of the ancillary cables for the water pumps, temperature sensor, etc.

This was the first time I have used a sensor panel and AIDA64. I was impressed with how much information is out there about creating displays, availability of templates, etc... Ended up showing a lot of information in a 800x480 display.

The case is sitting on a custom cut 24mm (1") thick piece of acrylic with a custom EL panel underneath for illumination.

Color(s): Blue Silver White

RGB Lighting? Yes

Theme: Case Mod

Cooling: Custom Liquid Cooling

Size: XL-ATX

Type: General Build

Hardware

CPU

$ 276.60

Motherboard

$ 592.39

Memory

$ 957.60

Graphics

$ 1,519.99

Storage

$ 249.99

PSU

$ 278.02

Cooling

Cooling

Cooling

CableMod

Monitor

$ 1,344.99

Keyboard

$ 168.00

Approved by: