Autonomous Mo-Ra

I had several ideas for my new build when I was planning it. First of all - I want ultimate performance, hence it should be parts like RTX 4090 and i9-13900ks. That's a lot of heat to dissipate, so of course it should be water cooled and had enough radiator surface area. I was also considering AMD and 5950x3d since 3d cache has benefits for gaming including aviasims, but I wanted to try delid and there was no ready solutions for delided ryzen on the market, only DIY ones.

Secondly I have a standing desk in my setup, in order for it to work - I either need extremely long cables if I place PC on the floor, or I need to place PC on the desk, which limits both weight and size of the PC. I don't like the idea of long cables because I already have a monitor arm and it uses about 150cm of cable. With PC standing on the floor I need additional 150 cm of cable to route it through table's cable guide and about 40-50 cm to reach the PC and make a radius. That means 3m cable is about 40-50cm short. But the next step for both USB 3.0 and DP cable is 5m with excessive 150cm of cable to hide somewhere, which is tough. Hence PC should be on the desk or should be somehow connected to the desk and move with it.

And I found the solution for that quite a long time ago - I can hang PC using table frame:

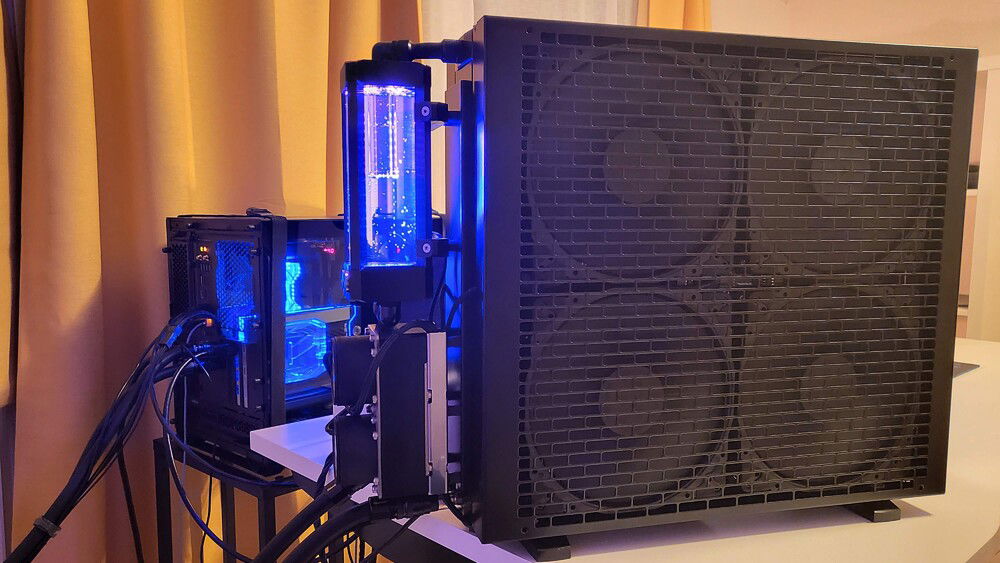

As result - I need most compact and light case for ATX components with no spare place required for cooling and apart from some SFF examples O11 Air Mini is the best choice for that. And I need external radiator and Mo-Ra is a well-known solution for that.

Second problem: how do I actually make Mo-Ra work?

For liquid - there is no such question, there are bunch of pass-throughs and quick disconnect fittings. But what about power? I need to power up two pumps and eight fans, that is more than 65w combined. I can use external power supply, but in that case I need second wall socket near radiator and I need to turn it on manually every time I turn on my PC. So the power need to be transferred from PC somehow.

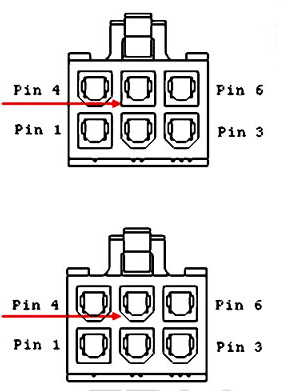

The answer I found is to use PCIe 6pin extender: many PSU manufacturers uses similar but quite different 6pin connector for their original sata/molex cables: PCIe 6pin connector has 2 square and 4 rounded pins while PSU connector has 3 square and 3 rounded pins.

You can connect PCIe extender into PSU - but you can't connect sata cable into extender. My original plan was to either swap connectors between extender and PSU cable or cut square pin on PSU cable to make it round. But it turned out that I don't even need to do that: for PCIe 6pin extenders usually 3square/3round connector is used and it is compatible with both PCIe cables and PSU cables. From several custom cables shops I've contacted Reaper Cable agreed to make 3m and 1.5m extensions for me and also they were kind enough to neither additionally charge me for length and custom nature of request nor for using 16AWG instead of default 18AWG to mitigate voltage drop and leave it under ATX specs for 5m total length / 90w load.

To control fans and pumps I've decided to use Corsair Core XT: mostly because it uses sata connector similar to EKWB pumps while other popular solutions like aquacomputer uses molex. I definitely can order cable with 3 sata or 3 molex connectors from CableMod - but they don't allow to have mixed connectors like 2 sata and 1 molex and they are very rigid in terms of custom requests outside of configurator. I also don't want to use sata-to-molex adapter because I need to hide all the wires somewhere and there is not much space on Mo-Ra to do that.

AS for EKWB pumps I've chosen them simply because I used them in the past and I know that they can go down to 800 rpm using PWM control - while for example said aquacomputer can go down only to 2000 rpm.

In the end Mo-Ra's feet were just high enough to hide Core XT under the radiator and I've hide all the sata power wires and connectors under the pumps module.

Core XT uses two water temperature sensors. First one is located before radiator and used to control pumps: if water after PC components is hot that pretty much means we are transitioning from idle to load and we need to speed up circulation. Second sensor is located between reservoir and pump and treated as water temperature after radiator: it control fans with the same logic, if water after radiator is hot we need to increase airflow.

For communication with Core XT via iCUE I use USB extension and 9pin internal header to USB adapter. Though after setting everything up USB connection is optional. Fan curves and RGB LED settings are stored on the controller, since fan curves uses temperature probes - we don't need CPU or GPU temperature as input. And connection is needed either to switch pre-saved profiles or to read temperature data for sake of your own curiosity.

Two additional problems came from PC itself. Initially my plan was to use vertical bracket and since it has 3 PCIe slots - two slots can be used for GPU itself and one slot for PCIe passthrough behind GPU. With that all tubes would be hidden behind GPU. But it turned out PCIe Passthrough is thicker than standard PCIe slot, fittings only make it worse and it conflicts with GPU backplate. It is possible to place passthrough in front of GPU since waterblock is thinner than 2 slots - but in that case all tubes would be visible. I ended up drilling two 20mm holes to solve this and stick to original plan with tubes behind GPU.

Second problem was soft tubes kink. The distance between GPU and CPU waterblock was not enough to use 45 degree fittings on CPU block, not enough space to make radius. 90 degree fittings would solve this problem, but I wanted to face both fittings down in order to minimize visible tubes and also in order not to cover waterblock. To face them down you need to use 20mm extender, which doesn't look nice. In the end I found a solution to use 2x 45 degree fittings and made an S-shape curve with two radiuses behind GPU: this allows to bend soft tube without kinking and also allows to route both tubes from CPU waterblock in the same direction.

Secondly I have a standing desk in my setup, in order for it to work - I either need extremely long cables if I place PC on the floor, or I need to place PC on the desk, which limits both weight and size of the PC. I don't like the idea of long cables because I already have a monitor arm and it uses about 150cm of cable. With PC standing on the floor I need additional 150 cm of cable to route it through table's cable guide and about 40-50 cm to reach the PC and make a radius. That means 3m cable is about 40-50cm short. But the next step for both USB 3.0 and DP cable is 5m with excessive 150cm of cable to hide somewhere, which is tough. Hence PC should be on the desk or should be somehow connected to the desk and move with it.

And I found the solution for that quite a long time ago - I can hang PC using table frame:

As result - I need most compact and light case for ATX components with no spare place required for cooling and apart from some SFF examples O11 Air Mini is the best choice for that. And I need external radiator and Mo-Ra is a well-known solution for that.

Second problem: how do I actually make Mo-Ra work?

For liquid - there is no such question, there are bunch of pass-throughs and quick disconnect fittings. But what about power? I need to power up two pumps and eight fans, that is more than 65w combined. I can use external power supply, but in that case I need second wall socket near radiator and I need to turn it on manually every time I turn on my PC. So the power need to be transferred from PC somehow.

The answer I found is to use PCIe 6pin extender: many PSU manufacturers uses similar but quite different 6pin connector for their original sata/molex cables: PCIe 6pin connector has 2 square and 4 rounded pins while PSU connector has 3 square and 3 rounded pins.

You can connect PCIe extender into PSU - but you can't connect sata cable into extender. My original plan was to either swap connectors between extender and PSU cable or cut square pin on PSU cable to make it round. But it turned out that I don't even need to do that: for PCIe 6pin extenders usually 3square/3round connector is used and it is compatible with both PCIe cables and PSU cables. From several custom cables shops I've contacted Reaper Cable agreed to make 3m and 1.5m extensions for me and also they were kind enough to neither additionally charge me for length and custom nature of request nor for using 16AWG instead of default 18AWG to mitigate voltage drop and leave it under ATX specs for 5m total length / 90w load.

To control fans and pumps I've decided to use Corsair Core XT: mostly because it uses sata connector similar to EKWB pumps while other popular solutions like aquacomputer uses molex. I definitely can order cable with 3 sata or 3 molex connectors from CableMod - but they don't allow to have mixed connectors like 2 sata and 1 molex and they are very rigid in terms of custom requests outside of configurator. I also don't want to use sata-to-molex adapter because I need to hide all the wires somewhere and there is not much space on Mo-Ra to do that.

AS for EKWB pumps I've chosen them simply because I used them in the past and I know that they can go down to 800 rpm using PWM control - while for example said aquacomputer can go down only to 2000 rpm.

In the end Mo-Ra's feet were just high enough to hide Core XT under the radiator and I've hide all the sata power wires and connectors under the pumps module.

Core XT uses two water temperature sensors. First one is located before radiator and used to control pumps: if water after PC components is hot that pretty much means we are transitioning from idle to load and we need to speed up circulation. Second sensor is located between reservoir and pump and treated as water temperature after radiator: it control fans with the same logic, if water after radiator is hot we need to increase airflow.

For communication with Core XT via iCUE I use USB extension and 9pin internal header to USB adapter. Though after setting everything up USB connection is optional. Fan curves and RGB LED settings are stored on the controller, since fan curves uses temperature probes - we don't need CPU or GPU temperature as input. And connection is needed either to switch pre-saved profiles or to read temperature data for sake of your own curiosity.

Two additional problems came from PC itself. Initially my plan was to use vertical bracket and since it has 3 PCIe slots - two slots can be used for GPU itself and one slot for PCIe passthrough behind GPU. With that all tubes would be hidden behind GPU. But it turned out PCIe Passthrough is thicker than standard PCIe slot, fittings only make it worse and it conflicts with GPU backplate. It is possible to place passthrough in front of GPU since waterblock is thinner than 2 slots - but in that case all tubes would be visible. I ended up drilling two 20mm holes to solve this and stick to original plan with tubes behind GPU.

Second problem was soft tubes kink. The distance between GPU and CPU waterblock was not enough to use 45 degree fittings on CPU block, not enough space to make radius. 90 degree fittings would solve this problem, but I wanted to face both fittings down in order to minimize visible tubes and also in order not to cover waterblock. To face them down you need to use 20mm extender, which doesn't look nice. In the end I found a solution to use 2x 45 degree fittings and made an S-shape curve with two radiuses behind GPU: this allows to bend soft tube without kinking and also allows to route both tubes from CPU waterblock in the same direction.

Color(s): Black

RGB Lighting? Yes

Theme: none

Cooling: Custom Liquid Cooling

Size: ATX

Type: General Build

Hardware

CPU

$ 539.99

Motherboard

$ 489.99

Memory

$ 462.23

Graphics

$ 3,329.95

Case

$ 110.00

Case Fan

$ 59.80

Case Fan

$ 59.80

Case Fan

$ 306.48

Cooling

$ 20.58

Cooling

$ 63.00

Cooling

$ 36.10

Cooling

$ 197.98

Cooling

Cooling

$ 98.94

Cooling

$ 122.64

Cooling

$ 94.00

Cooling

$ 242.00

Cooling

$ 150.00

Cooling

$ 420.00

Accessories

$ 214.02

Approved by: